Fresh-keeping process for frozen aquatic products

A process and aquatic product technology, applied in the field of frozen aquatic product preservation technology, can solve the problems of aquatic product meat quality, affecting aquatic product quality and edible value, nutrition loss, etc., to reduce the breeding of bacteria, improve the sterilization effect, and prolong the shelf life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

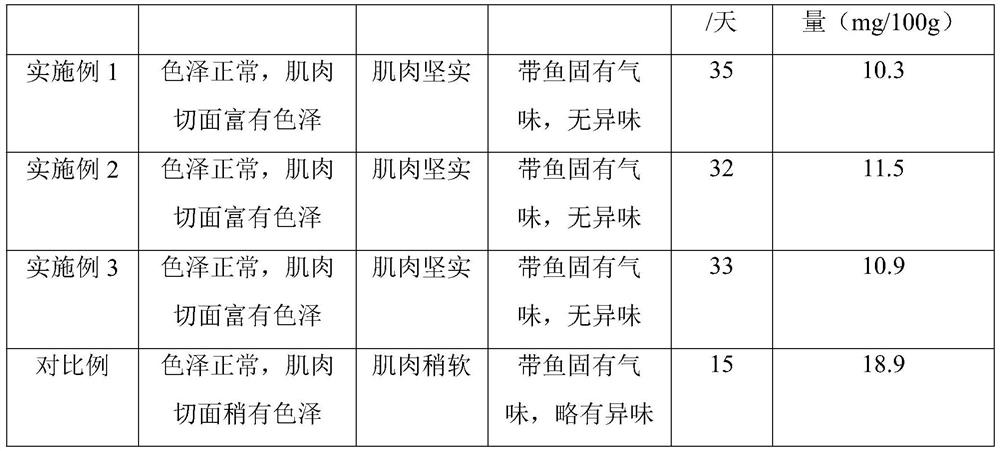

Embodiment 1

[0039]A frozen aquatic product preservation process, comprising the steps of:

[0040] S1. At room temperature, place aquatic products that have been fished for no more than 3 hours in clean water for cleaning, and then soak them in an appropriate amount of sterilizing solution for 30 minutes. Dirt on the surface; after soaking, fish out the aquatic product, wash the surface twice with clean water, drain the water on the surface, and then use ultraviolet rays to sterilize the front and back surfaces of the aquatic product;

[0041] S2. Take out the aquatic product after the ultraviolet sterilization treatment, and soak it in the preservative solution with an appropriate amount of low-temperature treatment, and the soaking time is 80 minutes; The product is placed in a low-temperature environment with a temperature of -18°C, so that a thin layer of fresh-keeping liquid ice film is formed on the surface of the aquatic product under low temperature conditions;

[0042] S3. Put t...

Embodiment 2

[0055] A frozen aquatic product preservation process, comprising the steps of:

[0056] S1. At room temperature, place aquatic products that have been fished for no more than 3 hours in clean water for cleaning, and then soak them in an appropriate amount of sterilizing solution for 40 minutes. Dirt on the surface; after soaking, fish out the aquatic product, wash the surface twice with clean water, drain the water on the surface, and then use ultraviolet rays to sterilize the front and back surfaces of the aquatic product;

[0057] S2. Take out the aquatic product after the ultraviolet sterilization treatment, and soak it in a fresh-keeping solution containing an appropriate amount of low-temperature treatment, and the soaking time is 100 minutes; The product is placed in a low-temperature environment with a temperature of -15°C, so that a thin layer of fresh-keeping liquid ice film is formed on the surface of the aquatic product under low temperature conditions;

[0058] S3...

Embodiment 3

[0071] A frozen aquatic product preservation process, comprising the steps of:

[0072] S1. At room temperature, place aquatic products that have been fished for no more than 3 hours in clean water for cleaning, and then soak them in an appropriate amount of bactericidal solution for 50 minutes. Dirt on the surface; after soaking, fish out the aquatic product, wash the surface with clean water for 3 times, drain the water on the surface, and then use ultraviolet rays to sterilize the front and back surfaces of the aquatic product;

[0073] S2. Take out the aquatic product after the ultraviolet sterilization treatment, and soak it in the preservative solution with an appropriate amount of low-temperature treatment, and the soaking time is 120min; The product is placed in a low-temperature environment with a temperature of -12°C, so that a thin layer of fresh-keeping liquid ice film is formed on the surface of the aquatic product under low temperature conditions;

[0074] S3. P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com