Electric flocculation and tubular micro-filtration coupled high-concentration brine deep defluorination device

A tubular microfiltration and tubular microfiltration membrane technology, applied in water pollutants, filtration treatment, water/sewage treatment, etc., can solve the problems of electrode coating corrosion, affecting the life of evaporative crystallizer, pitting corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

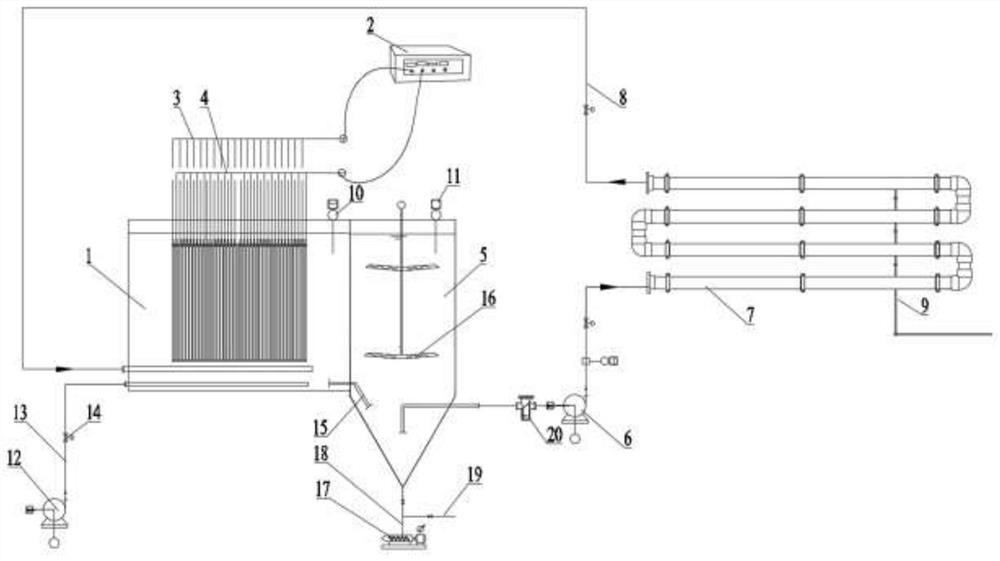

[0022] The specific implementation manner of the present invention will be described in more detail below with reference to schematic diagrams. The advantages and features of the present invention will be more apparent from the following description. It should be noted that all the drawings are in a very simplified form and use imprecise scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

[0023] Such as figure 1 As shown, this embodiment provides an electrocoagulation plus tubular microfiltration coupled high-concentration brine deep defluorination device for removing fluoride ions in high-concentration brine, including:

[0024] The electrocoagulation system includes a reaction cell 1 and an electrolytic assembly, the electrolytic assembly includes a periodic inverted DC power supply 2 and a plurality of positive electrode plates and a plurality of negative electrode plates located in the reaction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com