High-bearing bidirectional controllable locking mechanism

A locking mechanism and rod technology, applied in the field of robotics, can solve the problems of poor bearing capacity, complex structure, and single control function, and achieve the effect of simple and reliable control structure, large contact area, and strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

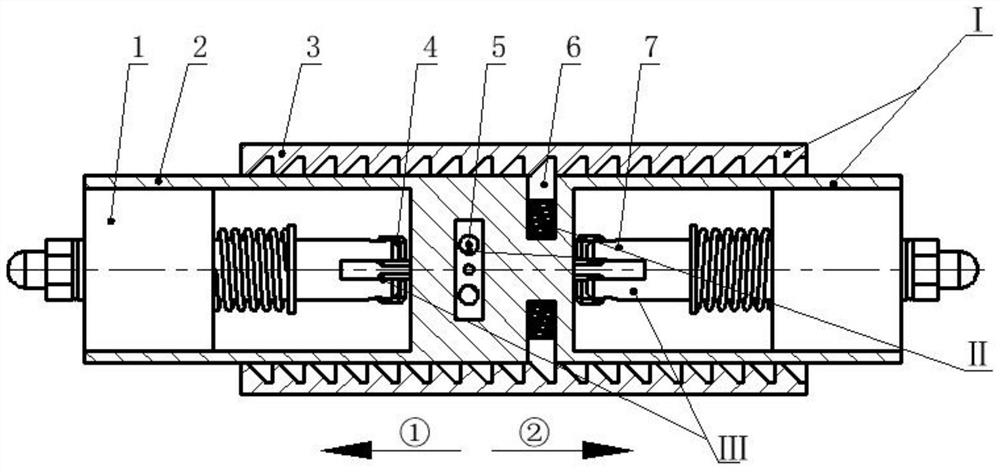

[0033] see figure 1 , a large-load two-way controllable locking mechanism, including an inner / outer rod group I, two pairs of spring slider groups II and two sets of actuators III; the inner / outer rod group I consists of two open ends The outer rod 3 is composed of a sliding sleeve and the inner rod 2, the two groups of actuators III are installed in the inner cavities at both ends of the inner rod 2, and the spring slider group II is installed in the middle of the inner rod 2 in the inner cavity. In the chute of the rod 2, it is connected with the actuator III through the wire rope 4; the actuator III drives the spring slider group II to reciprocate in the chute of the inner rod 2 under the working conditions of the specified combination. movement, to realize the engagement and release of the spring slider group II and the outer rod 3, and then to realize two-way sliding and locking. The locking mechanism of the present invention is applied in the deformable truss system, wh...

Embodiment 2

[0035] This embodiment is basically the same as Embodiment 1, and the special features are as follows:

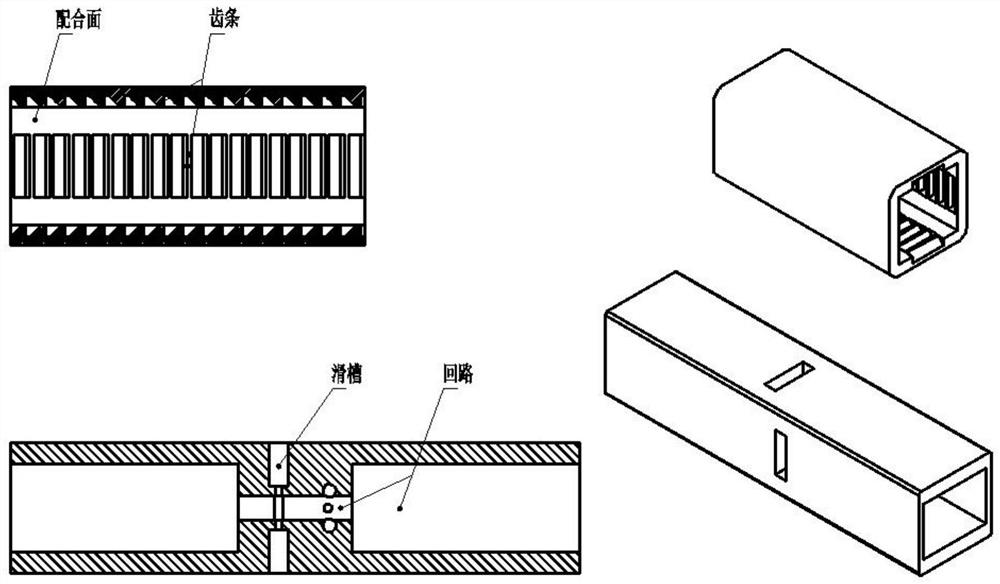

[0036] The inner wall of the outer rod 3 in the inner / outer rod group I is arranged with four sets of rack structures, and the two sets of rack structures that are parallel to each other have the same direction and the same pitch; the directions of the rack structures that are not parallel to each other Instead, the pitches are equal in size.

[0037] Between the inner wall of the outer rod 3 and the inner rod 2, needle rollers, or balls, or miniature sticks, or miniature pulleys are arranged as structures for anti-friction bearing and guiding.

[0038] The middle part of the inner rod 2 in the inner / outer rod group I is arranged with a guide chute for the slider 5 and the slider 6, and the two sliders 5, 6 are connected with the actuator 1, 7 through the wire rope 4 access.

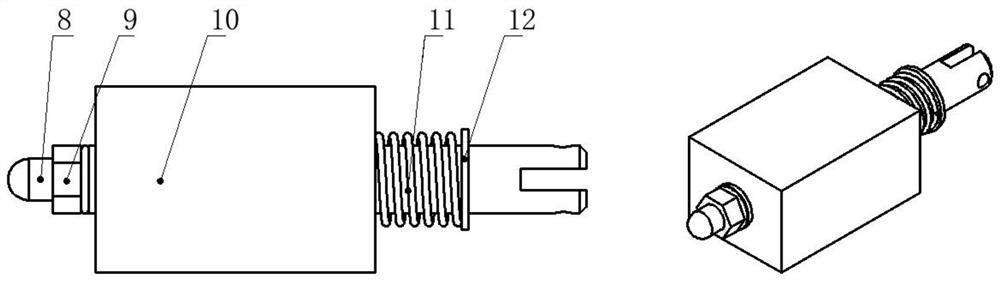

[0039] The spring slider group II is made up of a slider 13 and a spring 14. The front end of th...

Embodiment 3

[0048] Such as figure 2 with image 3 As shown, the inner / outer rod I is composed of an outer rod whose inner wall is a rack structure and an inner rod, and the inner and outer rods are matched by sliding contact.

[0049] Such as figure 2 with Figure 5 As shown, the spring slider group II is arranged in the chute of the inner rod, and the end of the slider is connected to the actuator through a wire rope. In the case of de-energization of the actuator, it locks with the rack structure of the outer rod. By controlling the two actuators, various working states can be controlled to control the sliding and locking of the two rods.

[0050] Such as figure 2 with Figure 4 As shown, the actuator III is composed of an iron core, a nut, an iron ring, a spring and a coil, etc., and is fixed on the inner rod.

[0051] The locking mechanism of this embodiment has four operation methods, including actuators 1 and 7 de-energized, actuators 1 and 7 working, actuator 1 working an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com