battery module

A battery module and battery technology, applied in the direction of batteries, battery components, secondary batteries, etc., can solve the problem of affecting the discharge power of the battery module, the limitation of the internal space size of the battery module, and the width and thickness of the connecting piece. Large problems, to avoid the situation of power limit in advance, optimize the structure and performance, the effect of short temperature transfer path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

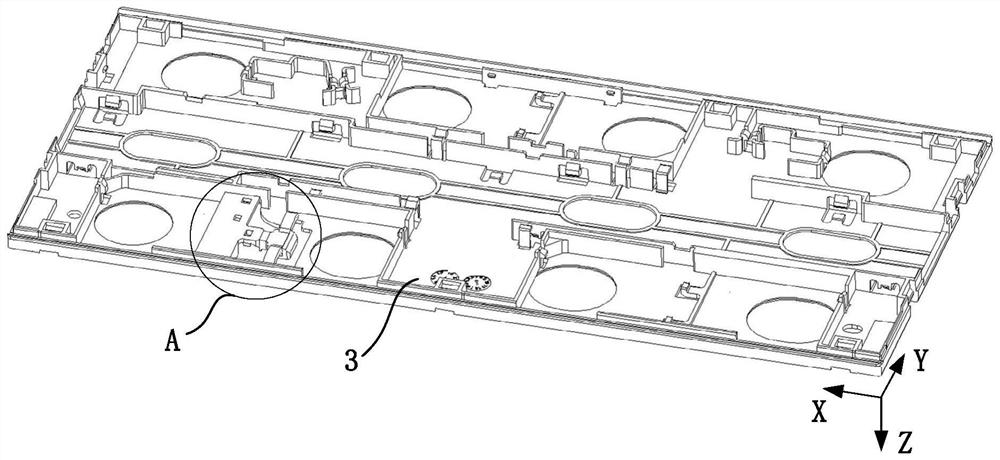

[0041] Combine below Figure 1 to Figure 15 The technical solution provided by the present invention is described in more detail.

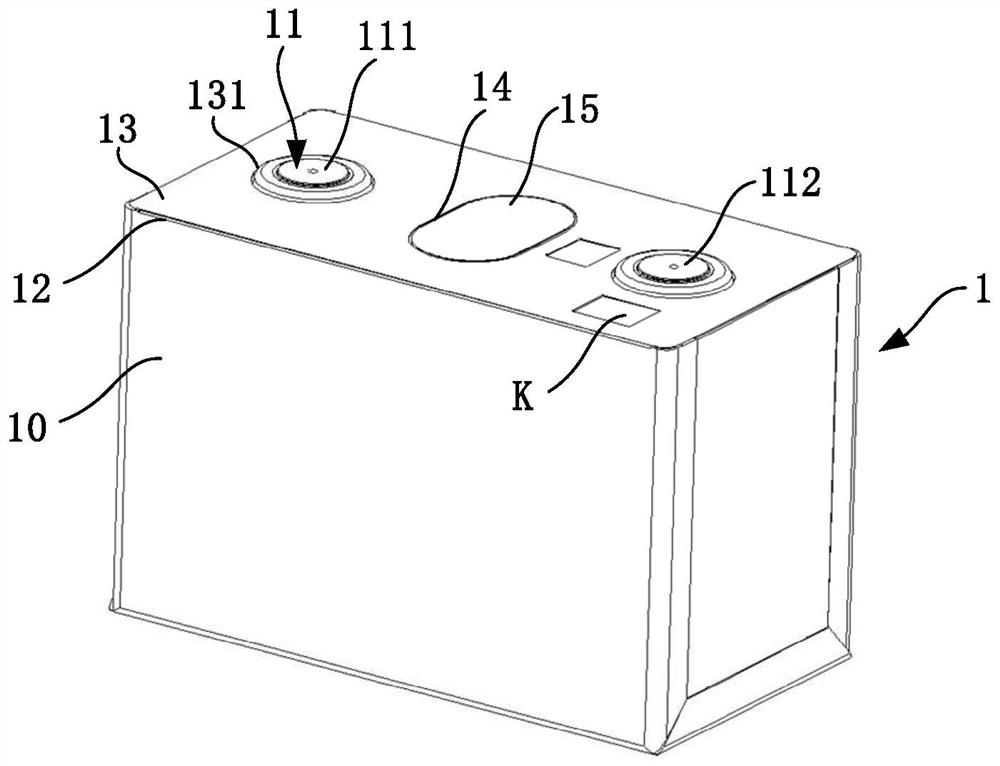

[0042] see Figure 1 to Figure 10 , the embodiment of the present invention provides a battery module, including a battery 1 , a connecting piece 2 , a wiring harness plate 3 and a heating assembly 4 . The battery 1 includes electrode terminals 11 and a top cover 12 . The connecting piece 2 is fixed to the electrode terminal 11 . The wire harness plate 3 is disposed on the top outside of the top cover 12 , and the wire harness plate 3 is provided with a mounting portion 31 and an elastic pressing portion 32 . The temperature collection component 4 is installed on the installation part 31 and is located between the wire harness plate 3 and the top cover 12 . Wherein, the elastic pressing part 32 is in contact with the connecting piece 2 , and the temperature collection assembly 4 is in contact with the top cover 12 .

[0043] The optional stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com