Method for analyzing micron-sized stamping bright spot defects of hot-dip galvanized automobile sheet

A technology of bright spot defect and analysis method, applied in the direction of analyzing materials, using wave/particle radiation for material analysis, measuring devices, etc., can solve the problem of stamping bright spot such defects that cannot be analyzed, etc., to facilitate the cause of the defect, easy to determine, design Scientifically rigorous results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033]Example 1 The hot-dip galvanized steel sheet in this example is HC180YD+Z, 0.7mm thick. The method for analyzing the stamping highlight defects of the micron-level hot-dip galvanized automobile sheet in this example includes the steps:

[0034](1) Simulated stamping

[0035]After simulated punching of the hot-dip galvanized steel sheet, it is cut into a punching sample of 1000mm×1000mm by a shearing machine.

[0036]The stamping highlight defect of micron-level hot-dip galvanized automobile sheet is a very concealed coating defect, which can not be found by naked eyes or a meter in the production stage, and usually occurs in the stamping process of automobile manufacturers. Therefore, in this embodiment, the hot-dip galvanized steel sheet is subjected to simulated stamping to make the stamping highlight defects appear.

[0037](2) Surface polishing

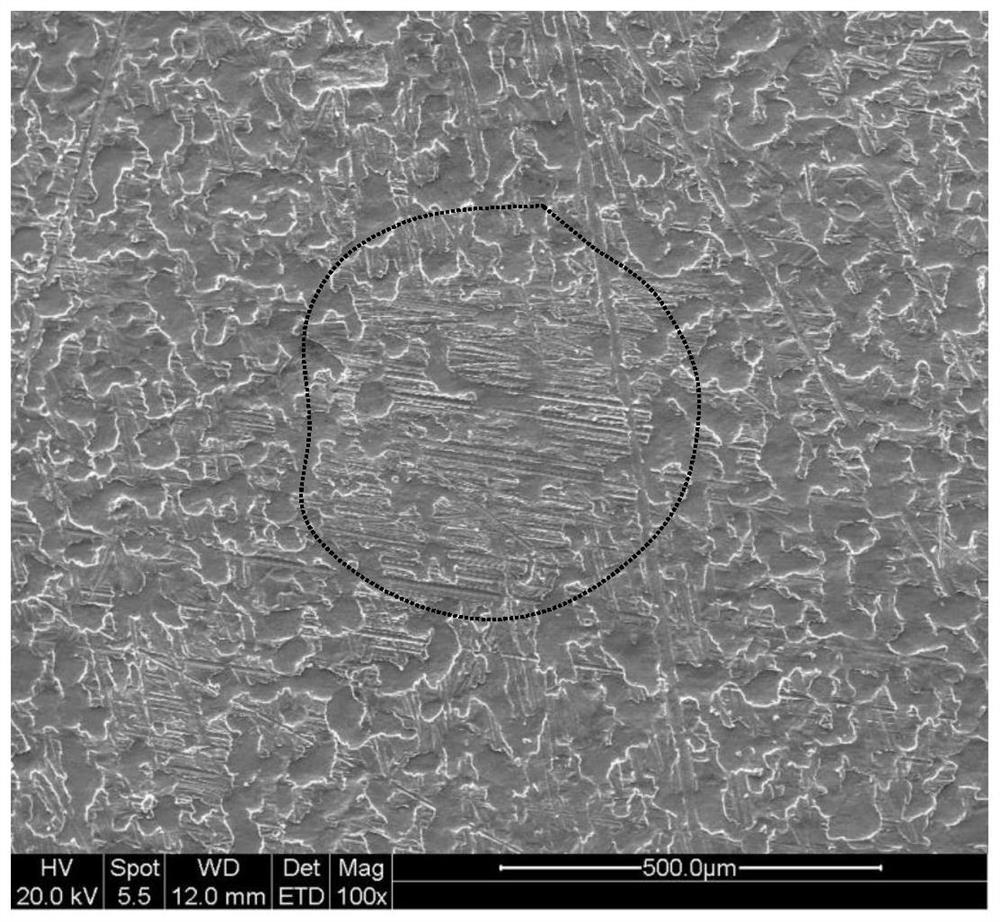

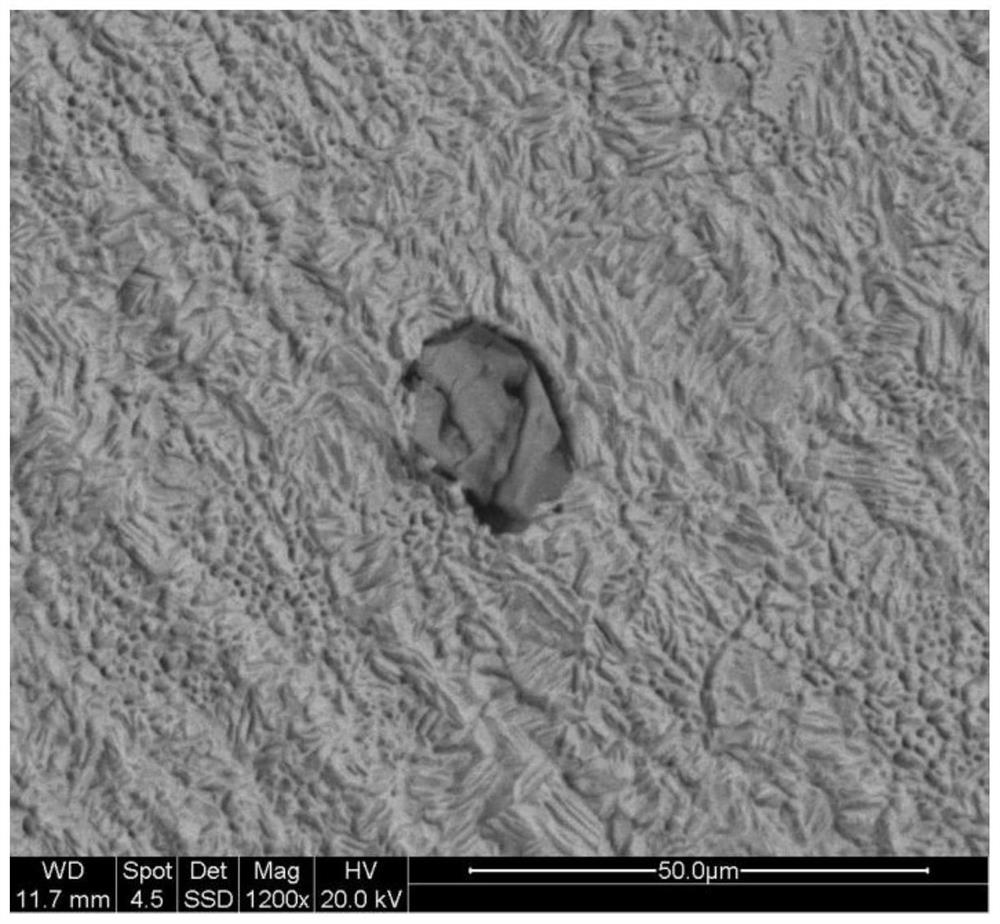

[0038]Place the stamped sample 2 on the observation table, which is composed of a stage and a fluorescent lamp with a lampshade, and then polis...

Embodiment 2

[0044]Embodiment 2 The hot-dip galvanized steel sheet of this embodiment is DC53D+Z, 0.8mm thick, and the method for analyzing the stamping highlight defects of the micron-level hot-dip galvanized automobile sheet of this embodiment includes the steps:

[0045](1) Simulated stamping

[0046]After simulated punching of the hot-dip galvanized steel sheet, it is cut into a punching sample of 1000mm×1000mm by a shearing machine.

[0047](2) Surface polishing

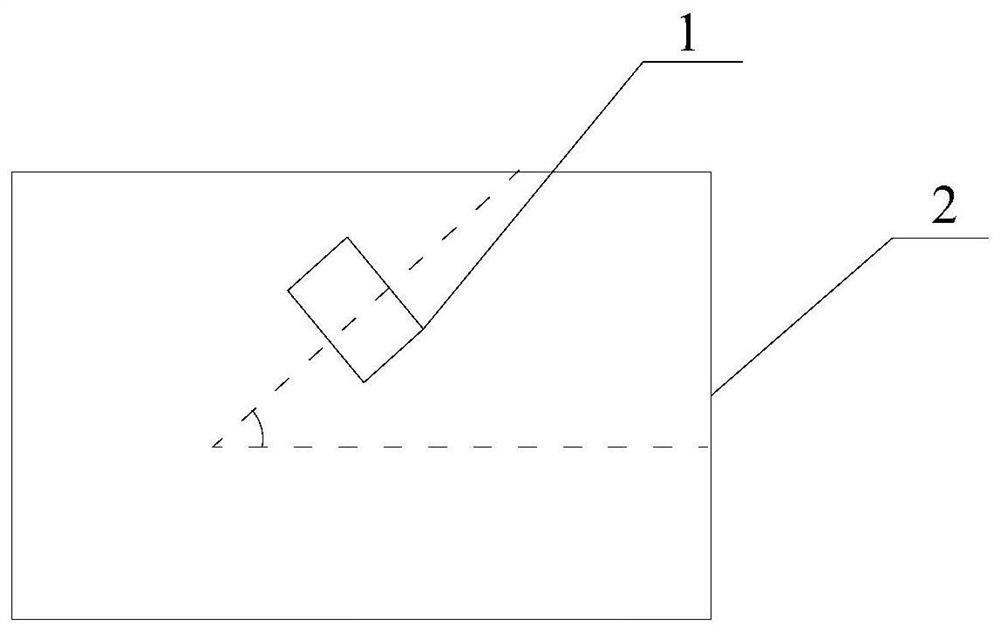

[0048]Place the stamped sample on the observation table, which is composed of a stage and a fluorescent lamp with a lampshade, and then polish the zinc layer on the surface of the stamped sample plate with a 1000-mesh oilstone.figure 1 As shown, keep the grinding direction at an angle of 30° with the rolling direction of the sample, and apply uniform pressure for unidirectional grinding. After the polishing is completed, press the sample plate surface and observe with the naked eye whether there are any bright spots under the illumination of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com