An aircraft model test attitude realization device

An aircraft model and attitude technology, applied in the field of aircraft model test attitude realization device, can solve the problem that the test project cannot achieve the required large angle of attack and large sideslip angle, and achieve scientific and rigorous design, ensure accuracy, and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

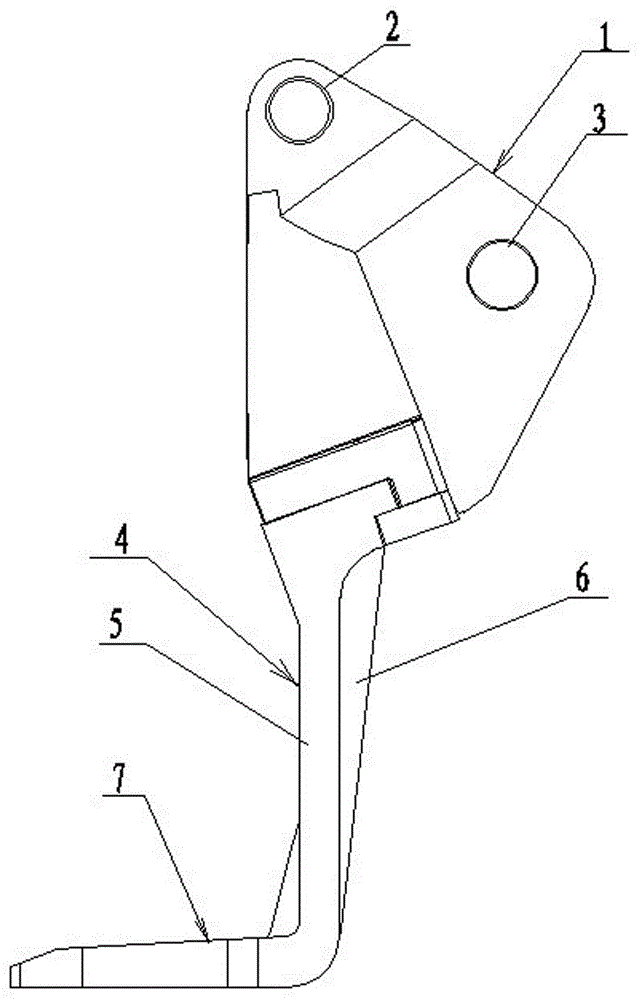

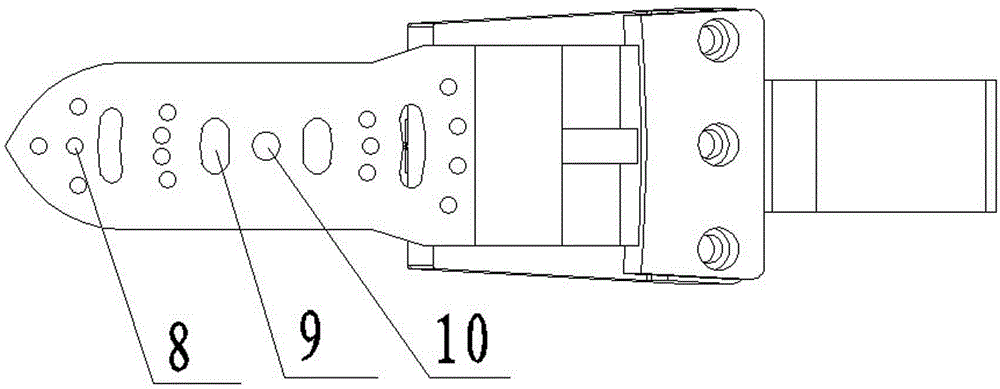

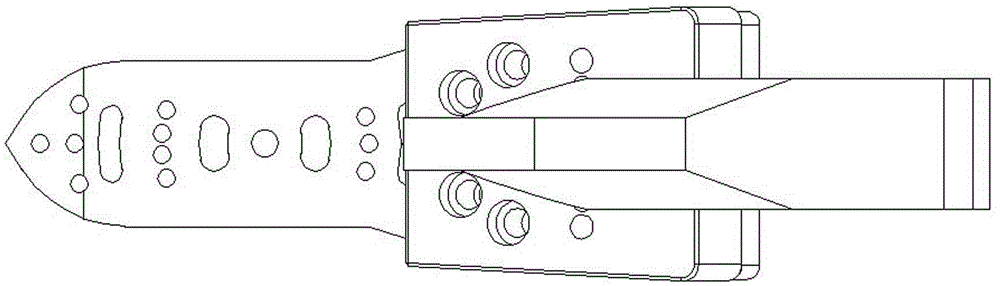

[0016] An aircraft model test attitude realization device includes a large joint 1, an extension section 4, and a pre-biased plate 7. The upper end of the large joint 1 is provided with two φ66 shaft holes 2 and φ62 shaft holes 3 for changing the angle of attack, and the lower end is provided with four M16 screw holes 12 and four φ14 pin holes 11 for changing the sideslip angle. The two φ66 shaft hole 2 and φ62 shaft hole 3 shaft holes at the upper end are connected with the shaft holes of the supporting plate four-bar linkage that changes the angle of attack in a known wind tunnel through two shafts, and can move with the four-bar linkage to change the angle of attack The four M16 screw holes 12 and the four φ14 pin holes 11 at the lower end of the large joint 1 are connected with the different screw holes and pin hole screw holes of the extension section 4 with screws and pins respectively, and can be connected with the extension section 4 through Different combinations of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com