Supercritical carbon dioxide sand-carrying coal seam fracturing device and method

A carbon dioxide, supercritical technology, applied in safety devices, container filling methods, container discharge methods, etc., can solve the problems of coal seam moisture freezing, hidden safety hazards in fracturing, complicated processes, etc., and achieve increased permeability and good flow diversion. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

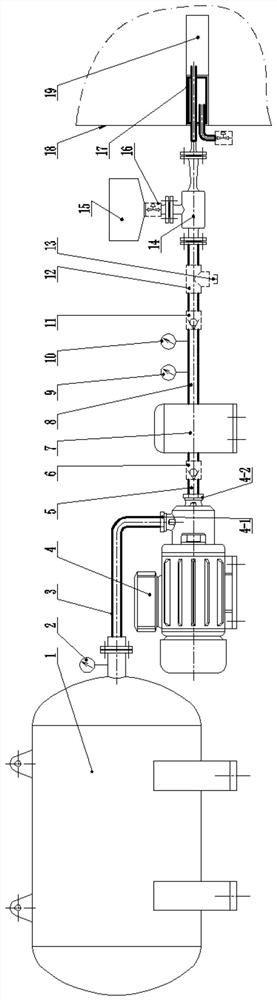

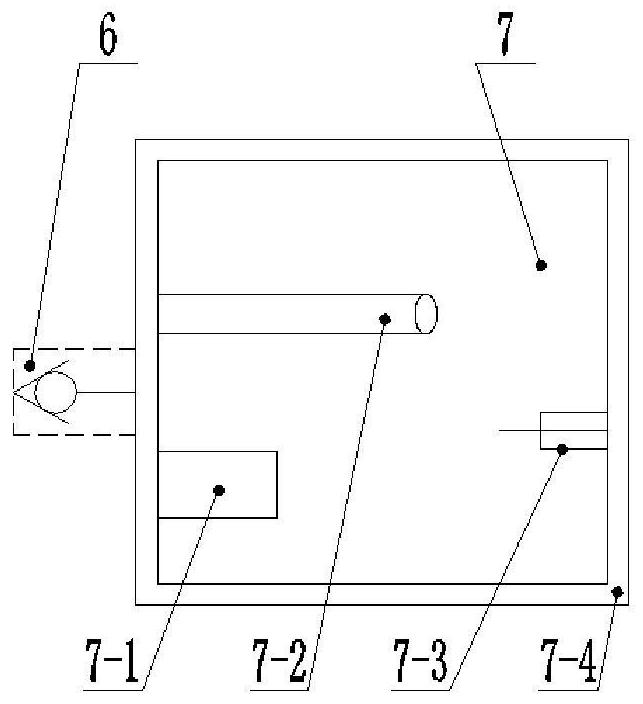

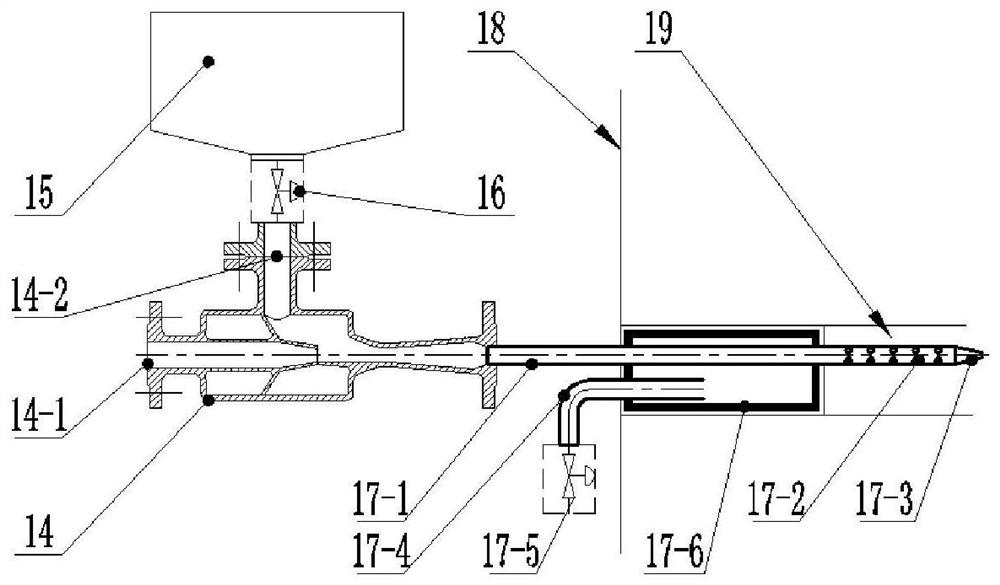

[0030] Such as figure 1 As shown, the present invention provides a supercritical carbon dioxide sand-carrying fracturing coal seam device, including liquid CO 2 Storage tank 1 , booster pump 4 , heating device 7 , high-pressure injector 14 , feeding barrel 15 , hole sealing device 17 , first hydraulic hose 3 , second hydraulic hose 5 and third hydraulic hose 8 . Wherein, the booster pump 4 includes a booster pump inlet 4-1 and a booster pump outlet 4-2, and the high-pressure injector 14 includes a working medium inlet 14-1, an injection medium inlet 14-2 and an outlet.

[0031] Liquid CO 2 A first pressure gauge 2 is provided at the outlet of the storage tank 1, and the liquid CO 2 The outlet of the storage tank 1 is connected to the inlet 4-1 of the booster pump through the first hydraulic hose 3, the outlet 4-2 of the booster pump is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com