Embedded and buckled type glass decorative brick and manufacturing method and equipment

A production method and technology of decorative bricks, applied in glass manufacturing equipment, glass pressing, glass molding, etc., can solve problems such as easy to fall off, achieve excellent quality, solve industry problems, and release thermal expansion stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

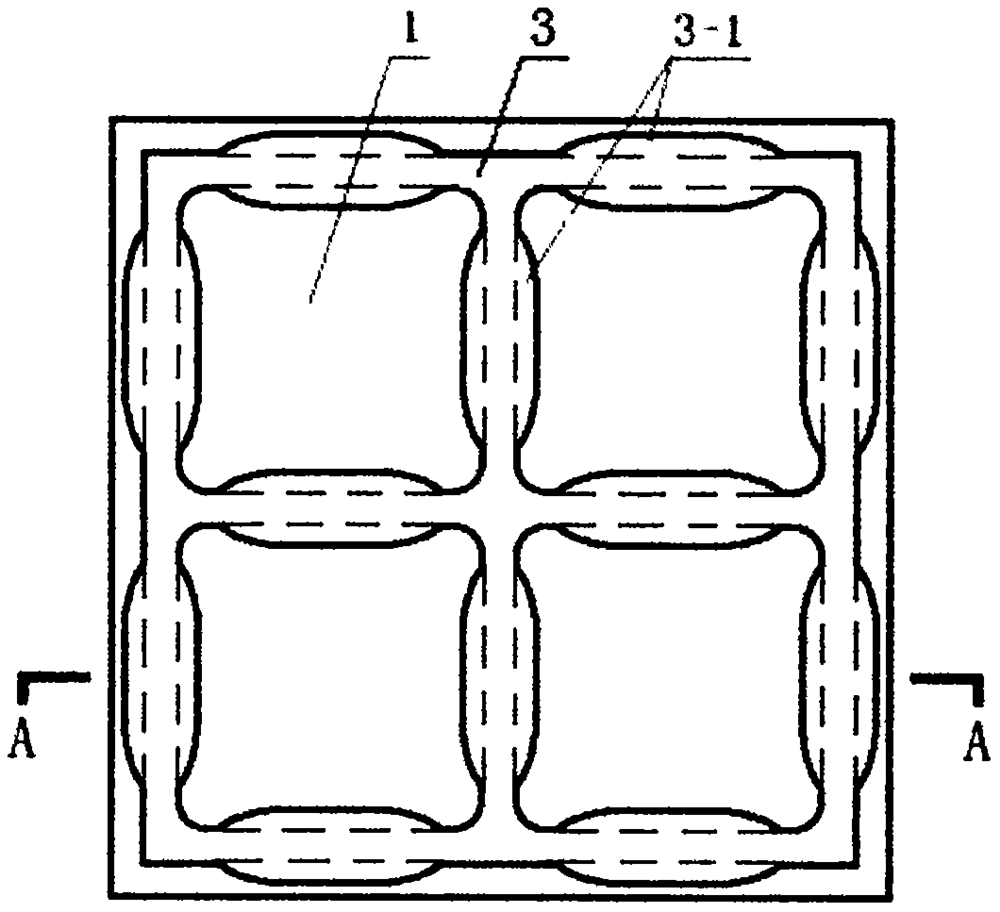

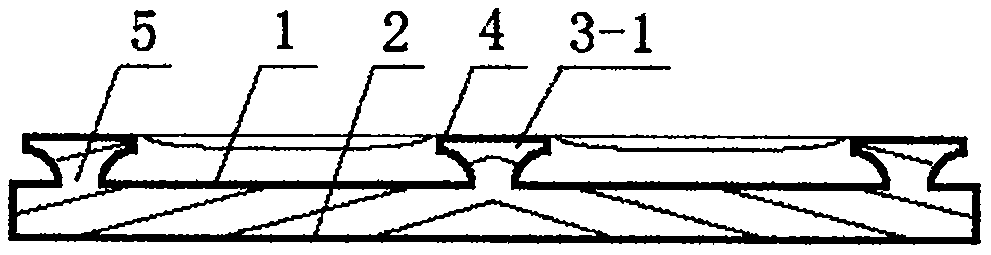

[0056] Embodiment one, according to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 Shown:

[0057] 1. An embedding type glass decorative brick, comprising an embedding surface (1) and a decorative surface (2), the embedding surface (1) is provided with an embedding piece protruding from the embedding surface by 1 mm to 10 mm, the embedding surface The fasteners (3) are arranged on the buckle surface (1) in the shape of strips, dots, squares or circles, and the upper part of the fasteners (3) gradually moves toward the two sides or from bottom to top or from top to bottom. One side is extended by 0.5 mm to 8 mm to form a dovetail embedded fastener (3-1) with a wide upper part (4) and a narrow lower part (5).

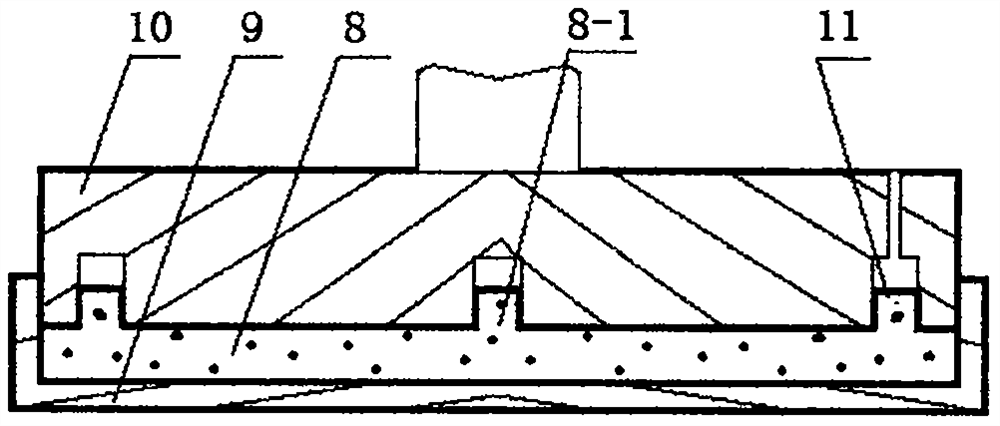

[0058] 2. Put the glass or glass-based mixed material (8) into the mold or base plate (9);

[0059] 3. Heat the glass or glass-based material (8) into a paste-like material (8-1) in an atmosphere of 500°C to 800°C or 800°C to 1200°C through a heating device...

Embodiment 2

[0063] Embodiment two, according to Figure 6 , Figure 7 , Figure 8 Shown:

[0064] 1. Use the rib forming roller (15) to roll form the preformed buckle rib (11) on the surface of the already hot-melted material (8-1);

[0065] 2. Use the extrusion scraper (12) to squeeze and scrape the upper part of the preformed buckle rib (11) or the corresponding part of the upper part downward one by one, so that the squeezed and scraped material (8-1) is pushed toward the two sides or one side. Side expansion to form a dovetail structure embedding rib (3-1), thus completing the product forming step;

[0066] 3. Put the product in the temperature range of 450°C to 650°C for annealing or tempering, that is to complete the production of an embedded glass decorative brick.

Embodiment 3

[0067] Embodiment three, according to Figure 9 , Figure 10 Shown, in conjunction with embodiment one, the preparation method described in embodiment two:

[0068] Put the forming rod (13) on the side of the corresponding part of the preformed buckle rib (11), then move the upper end of the formed rod (13) or move the formed rod (13) in an inclined state, so that the preformed buckle rib ( 11) The corresponding part is displaced laterally to form the inclined embedding rib (3-2), thus completing the forming step.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com