Rapid fabricated house and mounting method

An installation method and prefabricated technology, which are applied in the field of quick prefabricated houses and installations, can solve the problems of time-consuming installation, inconvenient installation, and inability to disassemble steel structure houses, and achieve the effect of improving efficiency and reducing assembly and disassembly time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

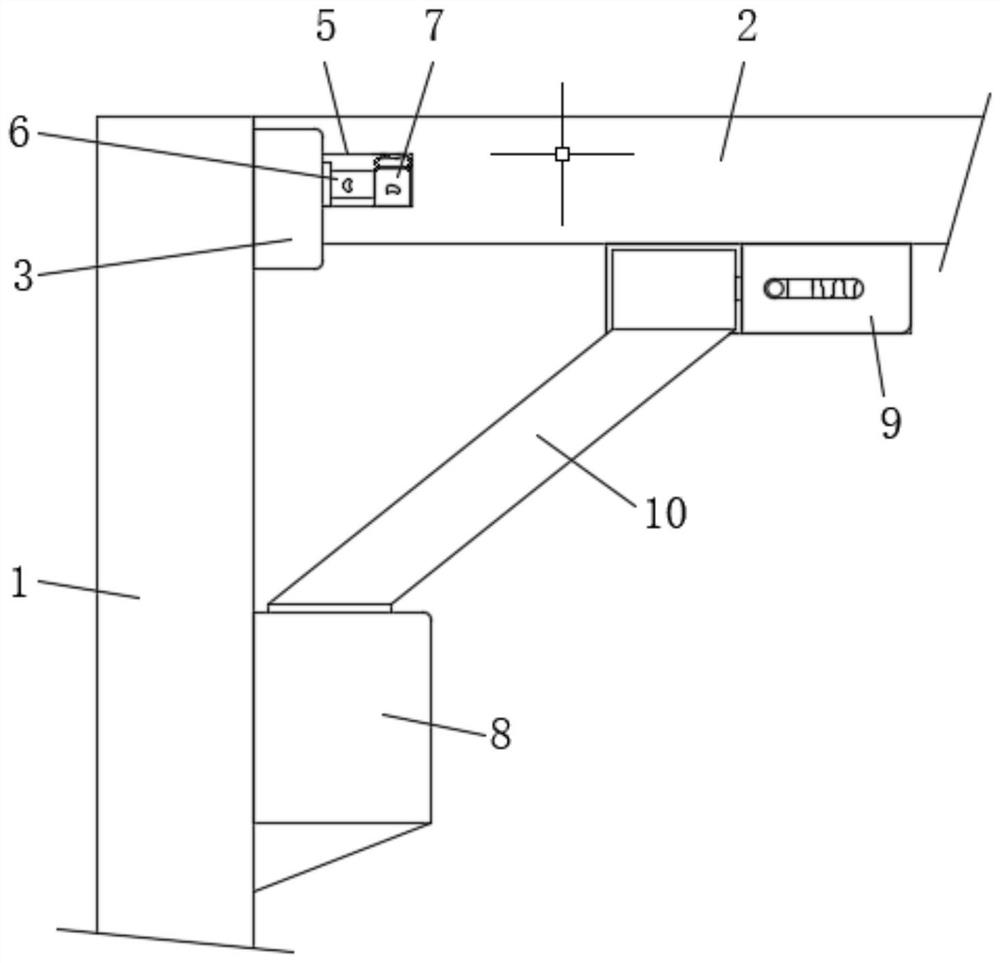

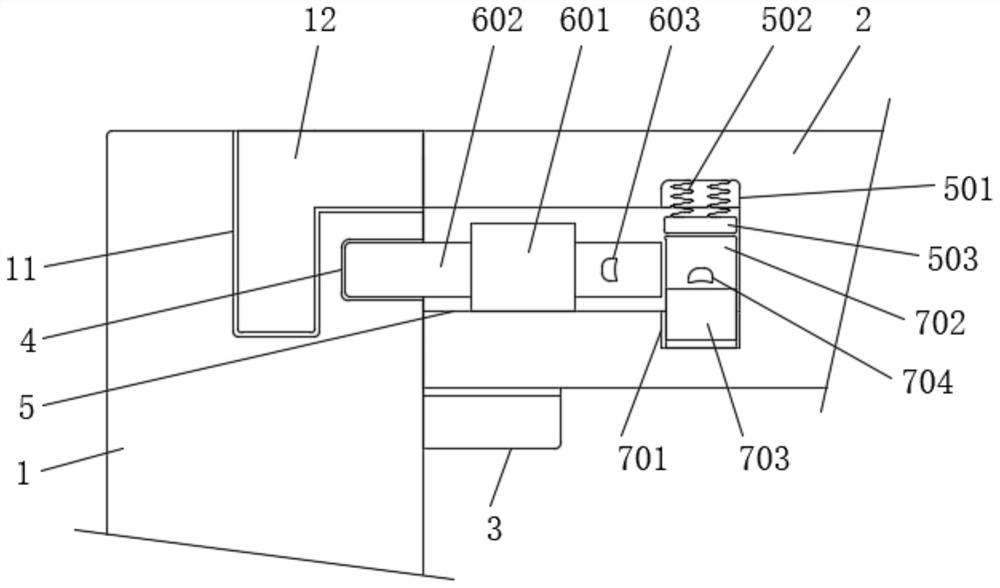

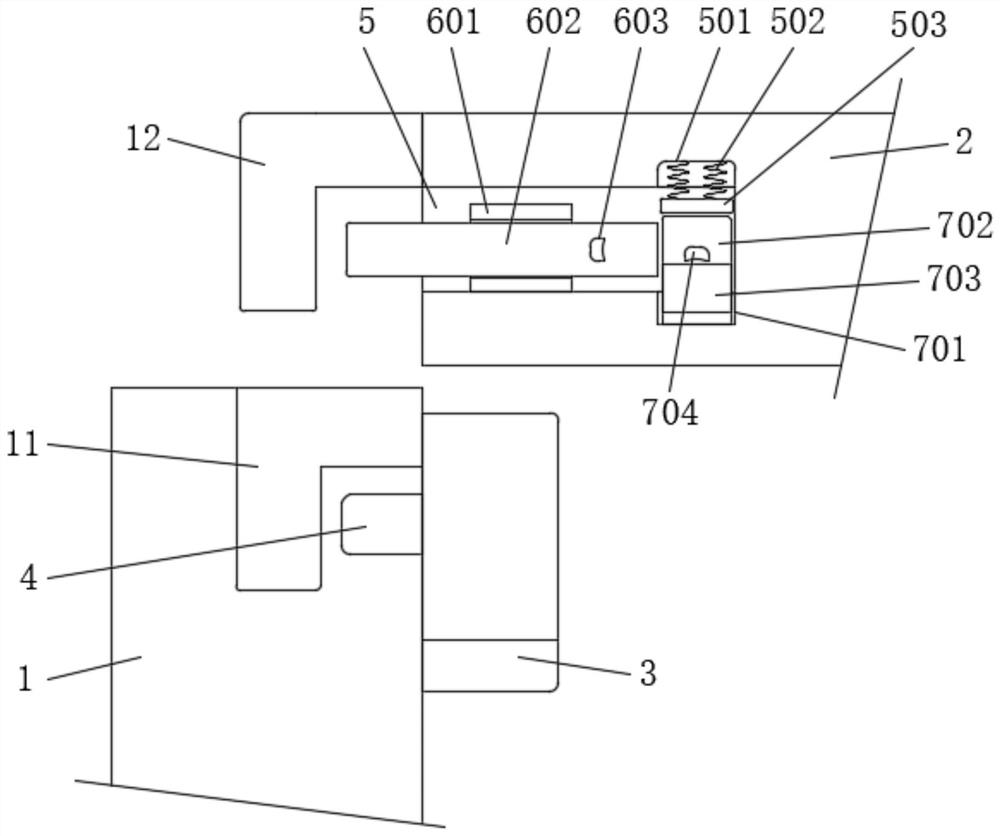

[0033] Embodiment one, by Figure 1 to Figure 6 Given, the present invention includes a steel structure column 1 and a steel structure beam 2, the upper part of the steel structure column 1 is fixedly installed with a U-shaped steel clip 3, and the upper part of the steel structure column 1 is located inside the U-shaped steel clip 3. The socket 4 is fixed, and the end of the steel structure beam 2 is movably clamped inside the U-shaped steel clip 3, so that the steel structure beam 2 can be stably connected with the steel structure column 1, and the two sides of the steel structure beam 2 Both ends are provided with a groove 5, one end of the groove 5 is installed with a fixed plug-in 6, one end of the fixed plug-in 6 is movably inserted into the fixed socket 4, and the other end of the groove 5 is equipped with a fixed stop 7, the steel structure The lower part of the column 1 is fixedly installed with the first fixed block 8, and the bottom of the steel structure beam 2 is ...

Embodiment 2

[0034] Embodiment two, on the basis of embodiment one, by figure 2 and image 3 Given, the top of the steel structure column 1 is provided with an L-shaped slot 11, the end of the steel structure beam 2 is fixedly connected with an L-shaped insert 12, and the L-shaped insert 12 is movably inserted into the inside of the L-shaped slot 11, Therefore, the steel structure beam 2 can maintain the stability of the lateral connection.

Embodiment 3

[0035] Embodiment three, on the basis of embodiment one, by figure 2 and image 3 Given, the fixed insert 6 includes a U-shaped piece 601, an insertion rod 602 and a first toggle block 603, the U-shaped piece 601 is fixedly installed at one end of the groove 5, and the insertion rod 602 is movably inserted into the inside of the U-shaped piece 601, The first toggle block 603 is fixedly installed on one side of the insertion rod 602, and one end of the insertion rod 602 is movably inserted into the fixed socket 4, so that the steel structure beam 2 can maintain the stability of the vertical connection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com