A semiconductor process equipment

A process equipment and semiconductor technology, applied in the direction of crystal growth, chemical reactive gas, single crystal growth, etc., can solve the problem of high deposition speed of epitaxial layer at the edge of the substrate, and achieve the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be understood that the specific embodiments described herein are only used to illustrate and explain the present invention, but not to limit the present invention.

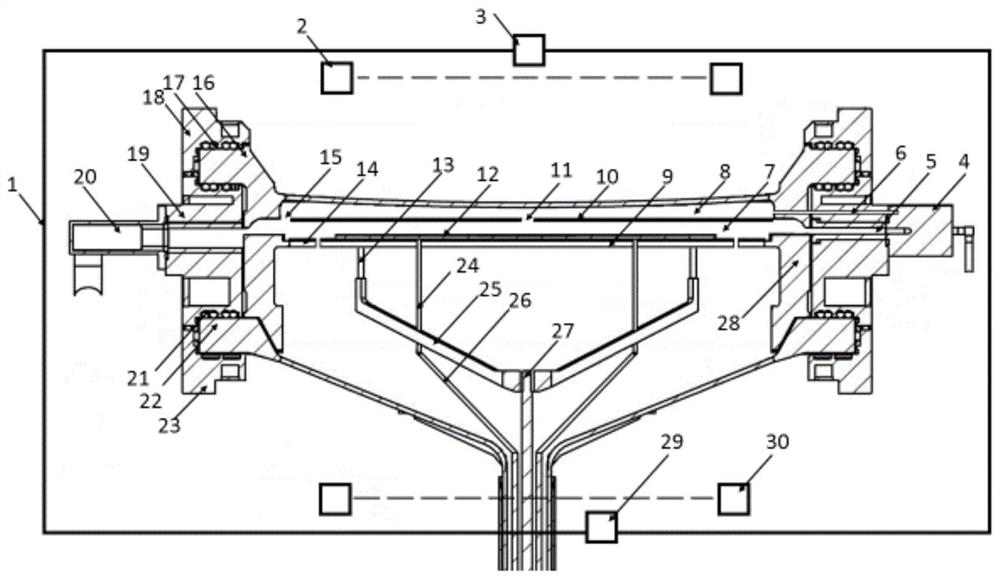

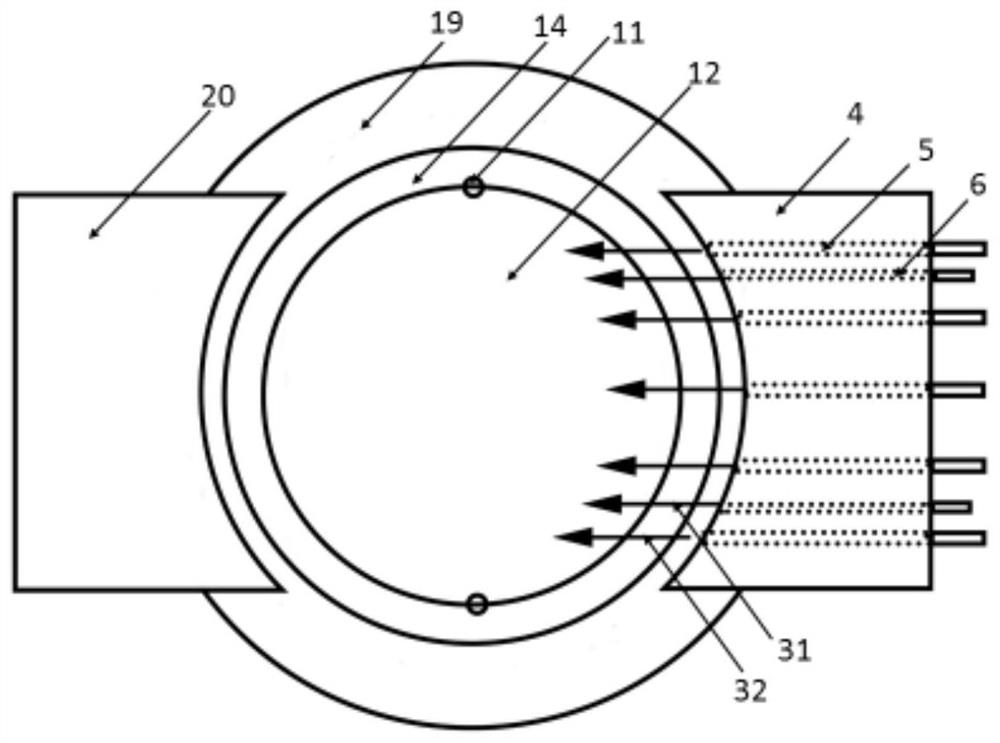

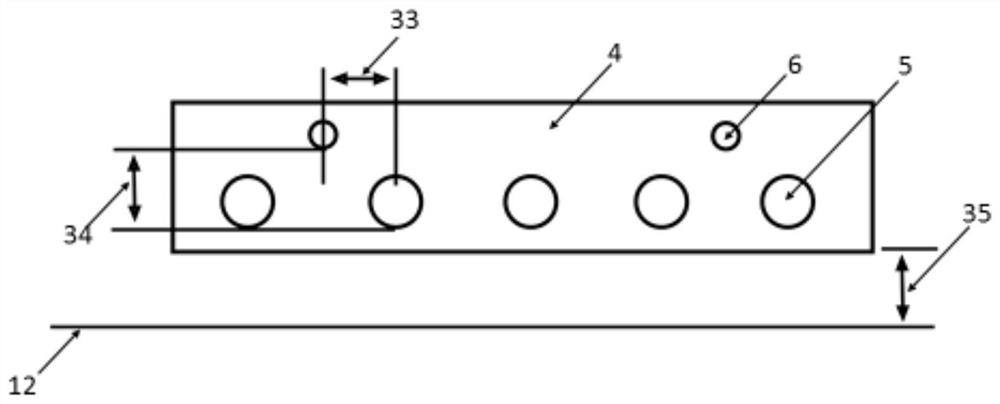

[0024] To solve the above problems, such as figure 1 As shown, the present invention provides a semiconductor process equipment, including a process chamber, a carrier plate 9 and a process spacer 10 arranged in the process chamber, the process spacer 10 and the carrier plate 9 are arranged in parallel, and the process spacer 10 and the carrier plate 10 are arranged in parallel. A main airflow area 7 is formed between the trays 9 , and a secondary airflow area 8 is formed on the side of the process partition 10 away from the carrier tray 9 (between the process partition 10 and the upper cover 16 ).

[0025] The inner wall of the process chamber has an exhaust port and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com