Spiced vinegar brewing process

A technology of spiced vinegar and technology, which is applied in the field of spiced vinegar brewing technology, can solve the problems of exacerbation of the disease, lack of treatment, and ineffective effect, etc., achieve good therapeutic effect, improve body resistance, and have the effect of fragrant smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

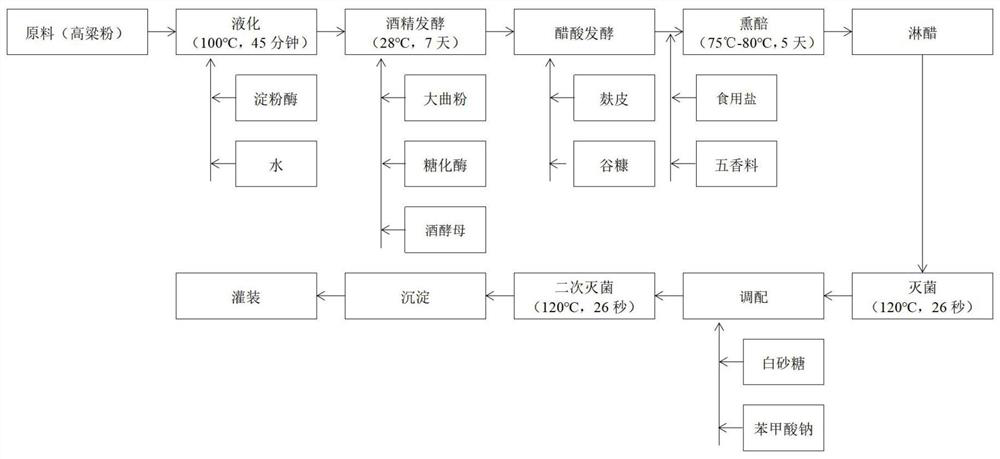

[0034] see figure 1 , a spiced vinegar brewing process, comprising the following steps:

[0035] S1: raw material preparation: by weight, 20 parts of sorghum flour, 4 parts of Daqu powder, 0.8 part of amylase, 0.004 part of glucoamylase, 0.002 part of wine yeast, 20 parts of bran, 40 parts of rice bran, 1 part of edible salt, 0.8 parts of five spices, 1 part of white sugar and 0.4 parts of sodium benzoate;

[0036] S2: Liquefaction: Put the sorghum flour into the liquefaction tank, add 5 times the amount of water and amylase, heat the liquefaction tank to 100°C, and keep it for 45 minutes;

[0037] S3: Alcoholic fermentation: After cooling the sorghum liquor liquefied in step S2 to 28°C, add Dakoji powder, glucoamylase and brewer's yeast, and ferment for 7 days;

[0038] S4: Acetic acid fermentation: Add bran and rice bran to the wine mash fermented in step S3, and put it into the tank for acetic acid fermentation. After eight days, the acidity of the vinegar grains reaches ...

Embodiment 2

[0053] see figure 1 , a spiced vinegar brewing process, comprising the following steps:

[0054] S1: raw material preparation: by weight, 25 parts of sorghum flour, 5 parts of Daqu powder, 1 part of amylase, 0.005 part of glucoamylase, 0.003 part of wine yeast, 25 parts of bran, 45 parts of rice bran, 2 parts of edible salt, 1 part of five spices, 10 parts of white sugar and 0.6 part of sodium benzoate;

[0055]S2: Liquefaction: Put the sorghum flour into the liquefaction tank, add 5 times the amount of water and amylase, heat the liquefaction tank to 100°C, and keep it for 45 minutes;

[0056] S3: Alcoholic fermentation: After cooling the sorghum liquor liquefied in step S2 to 28°C, add Dakoji powder, glucoamylase and brewer's yeast, and ferment for 7 days;

[0057] S4: Acetic acid fermentation: Add bran and rice bran to the wine mash fermented in step S3, and put it into the tank for acetic acid fermentation. After eight days, the acidity of the vinegar grains reaches more...

Embodiment 3

[0072] see figure 1 , a spiced vinegar brewing process, comprising the following steps:

[0073] S1: raw material preparation: by weight, 30 parts of sorghum flour, 6 parts of Daqu powder, 1.2 parts of amylase, 0.006 part of glucoamylase, 0.004 part of wine yeast, 30 parts of bran, 50 parts of rice bran, 3 parts of edible salt, 1.2 parts of five spices, 20 parts of white sugar and 0.8 parts of sodium benzoate;

[0074] S2: Liquefaction: Put the sorghum flour into the liquefaction tank, add 5 times the amount of water and amylase, heat the liquefaction tank to 100°C, and keep it for 45 minutes;

[0075] S3: Alcoholic fermentation: After cooling the sorghum liquor liquefied in step S2 to 28°C, add Dakoji powder, glucoamylase and brewer's yeast, and ferment for 7 days;

[0076] S4: Acetic acid fermentation: Add bran and rice bran to the wine mash fermented in step S3, and put it into the tank for acetic acid fermentation. After eight days, the acidity of the vinegar grains reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com