Soft oil-resistant flame-retardant polyvinyl chloride material and preparation method thereof

A flame-retardant polyvinyl chloride and oil-resistant technology, used in plastic/resin/wax insulators, organic insulators, electrical components, etc., can solve the problem of electrical materials and building materials with poor flame retardant properties and can not meet the use of cables with high bundle burning , The cable material cannot meet the flame retardant standard and other problems, and achieve the effect of excellent mechanical properties, good mechanical properties, and small mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

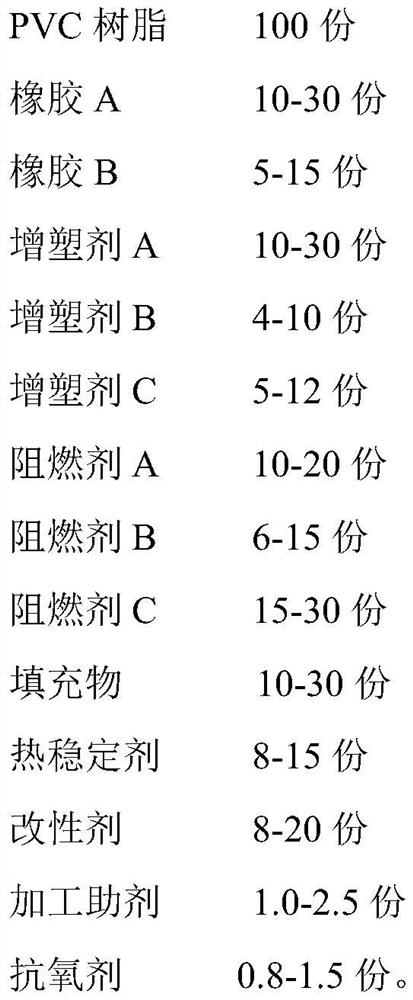

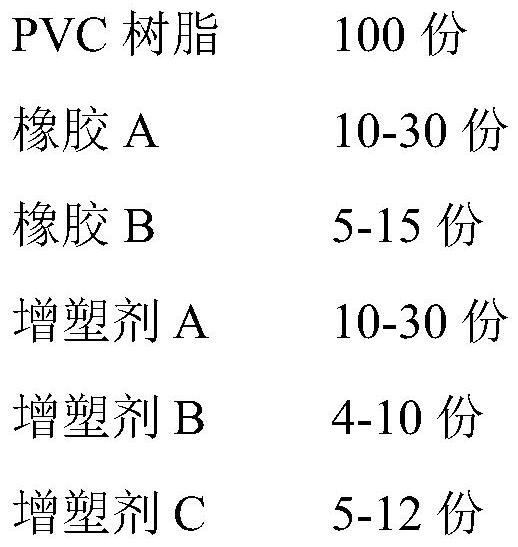

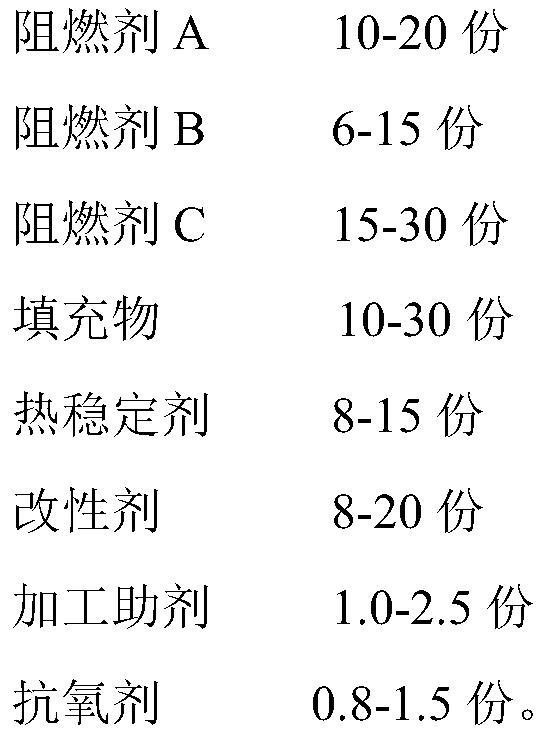

Method used

Image

Examples

preparation example Construction

[0056] The embodiment of the invention also discloses a method for preparing a soft, oil-resistant and flame-retardant polyvinyl chloride material, which specifically includes the following steps:

[0057] 1) According to the above-mentioned soft oil-resistant flame-retardant polyvinyl chloride material, take each raw material for subsequent use;

[0058] 2) Add PVC resin, plasticizer A, plasticizer B, plasticizer C, flame retardant A, flame retardant B, flame retardant C and heat stabilizer to a high-speed kneader for stirring and mixing, set The jacket temperature of the mixer is 95°C-105°C, and the mixing time is 5-10 minutes; then add rubber A, rubber B, modifier, processing aid and antioxidant to the high-speed kneader, and mix for 30-90 seconds to obtain a uniform the mixture;

[0059] 3) Put the mixture into a two-stage extrusion granulator composed of twin-screw and single-screw. The heating temperature of each section of the twin-screw granulator is uniformly increas...

Embodiment 1~6

[0061] Embodiments 1 to 6 of the present invention disclose a method for preparing a soft, oil-resistant and flame-retardant polyvinyl chloride material, which specifically includes the following steps, wherein the composition and proportioning ratio of the raw materials are shown in Table 1, and various technical parameters are shown in Table 2 below:

[0062] 1) taking each raw material for subsequent use;

[0063] Among them, PVC resin was purchased from Ningbo Formosa Plastics Company; rubber was purchased from France Ilio Company; plasticizer was purchased from Jiangsu Senhe Company; flame retardant A was purchased from Muli Antimony Industry Company; flame retardant C was purchased from American Yabao Company ; Calcium-zinc composite heat stabilizer was purchased from German Bear Company.

[0064] 2) Add PVC resin, plasticizer A, plasticizer B, plasticizer C, flame retardant A, flame retardant B, flame retardant C and heat stabilizer to a high-speed kneader for stirring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com