Winding device with cutting function for textile raw material production and processing

A rewinding device and functional technology, which is applied in the field of rewinding devices for the production and processing of textile raw materials, can solve the problems of stopping the equipment for a long time, reducing the work efficiency, delaying the work progress, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

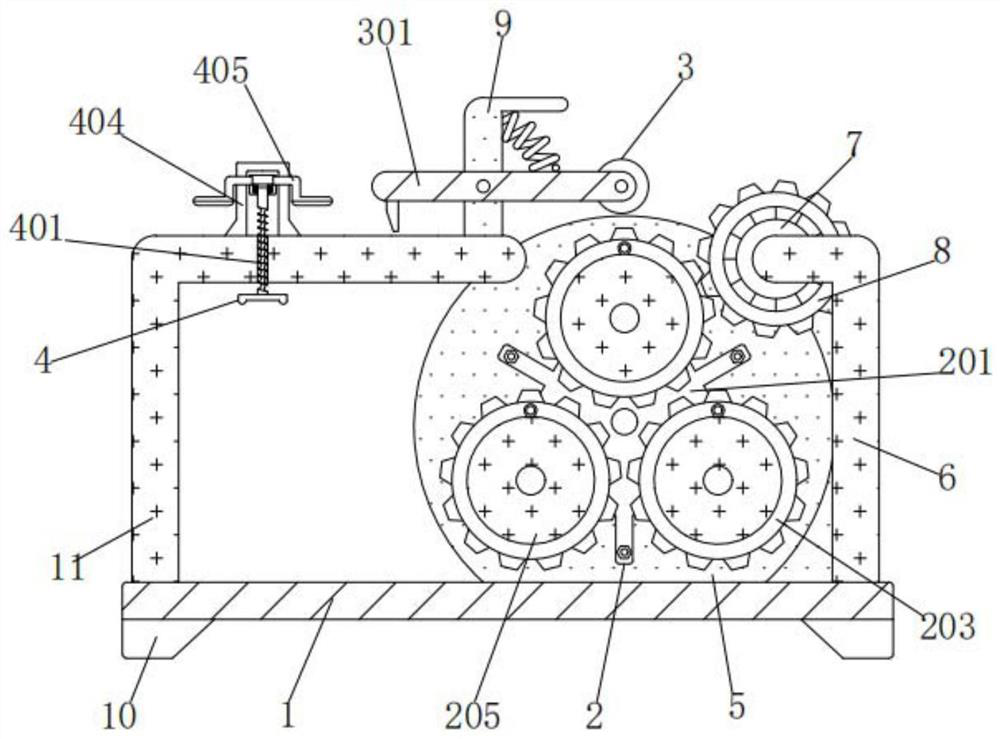

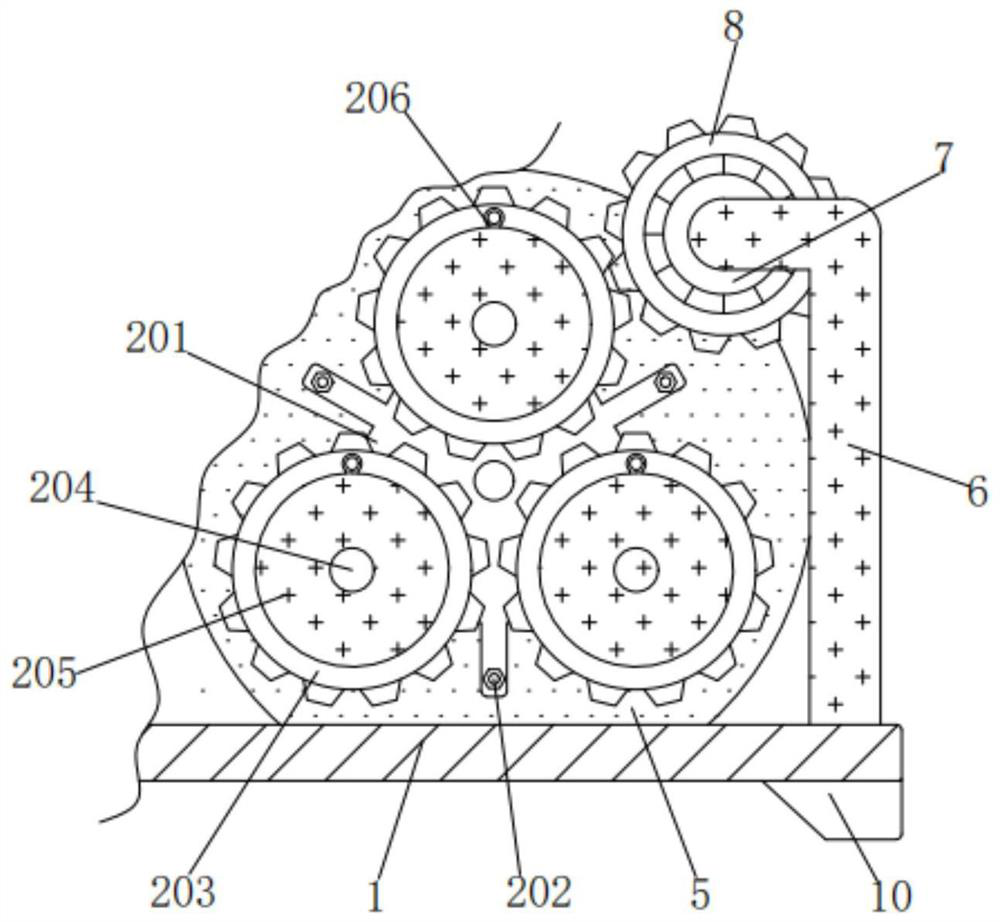

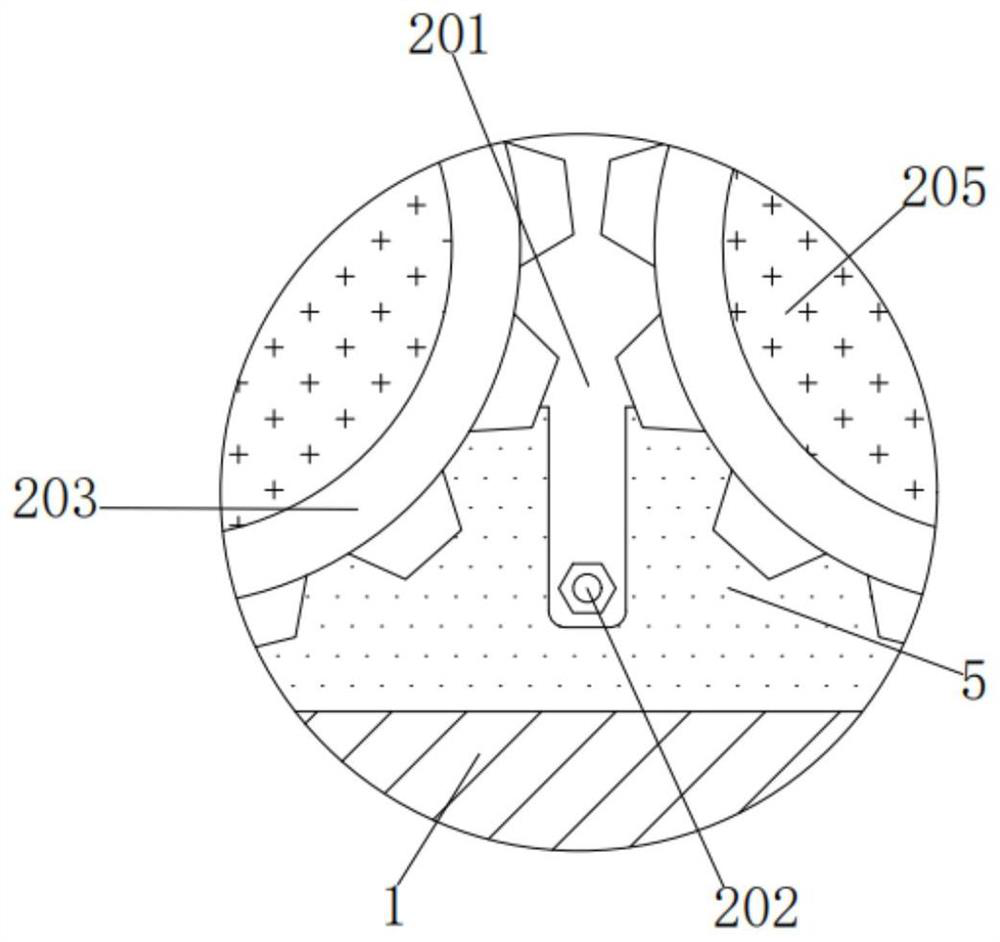

[0035] A winding device for the production and processing of textile raw materials with a cutting function, comprising a bottom plate 1, a circular plate 5 is fixedly connected to the top right side of the bottom plate 1, and an adjusting mechanism 2 is installed on the front of the circular plate 5, and the adjusting mechanism 2 includes a curved Plate 201, bolt 202, first gear 203, round rod 204, cylinder 205 and ring 206, the inner wall of curved plate 201 is connected to the front of circular plate 5 in rotation, and the force of curved plate 201 is carried out through the pin shaft on the front of circular plate 5. Rotate, the front of circular plate 5 is equidistantly threaded with bolts 202, the outer walls of multiple bolts 202 are respectively threaded equidistantly with the front of circular plate 5, and the front equidistant of curved plate 201 is rotated with the inner walls of multiple first gears 203 Connected, the first gear 203 is forced to rotate through the fr...

Embodiment 2

[0038] As an option, see figure 1 and 5 , a winding device for textile raw material production and processing with a cutting function, a cutting mechanism 3 is installed on the front of the vertical plate 9, and the cutting mechanism 3 includes a horizontal plate 301, a knife 302, a spring 303 and a roller 304, and the inner wall of the horizontal plate 301 is connected to the The front of vertical plate 9 rotates and connects, and horizontal plate 301 is stressed and rotates through vertical plate 9 front pin shafts, and the bottom left side of horizontal plate 301 is fixedly connected with the top of cutter 302, and the top right side of horizontal plate 301 is connected with spring 303. The bottom is fixedly connected, the top of the spring 303 is fixedly connected to the upper right side of the vertical plate 9, the right side of the rear end surface of the horizontal plate 301 is connected to the front rotation of the roller 304, and the horizontal plate 301, the spring 3...

Embodiment 3

[0041] As an option, see figure 1 and 6, a winding device for the production and processing of textile raw materials with a cutting function, a limiting mechanism 4 is installed on the left side of the front of the second curved plate 11, and the limiting mechanism 4 includes a threaded rod 401, a handle 402, a block 403, a square frame 404 and the second A bent plate 405, the outer wall thread of the threaded rod 401 is threadedly connected with the front left side of the second curved plate 11, the bottom of the threaded rod 401 is affixed to the top of the handle 402, the handle 402 is convenient to rotate the threaded rod 401, the threaded rod 401 The top of the threaded rod 401 is rotationally connected with the bottom of the square frame 403, the top of the threaded rod 401 is forced to rotate through the bearing at the bottom of the square frame 403, the outer wall of the block 403 is slidingly engaged with the inner wall of the square frame 404, and the block 403 is fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com