Novel container vibrating table

A container and vibrating table technology, applied in loading/unloading, transportation and packaging, conveyors, etc., can solve the problems of waste of resources, underloading, etc., and achieve prolonging service life, reducing material volume, and high safety and reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

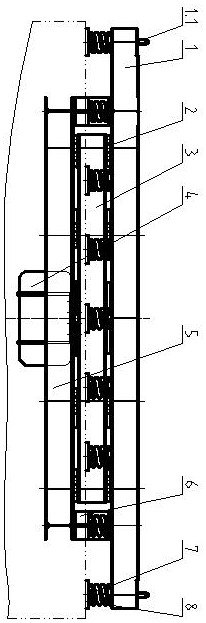

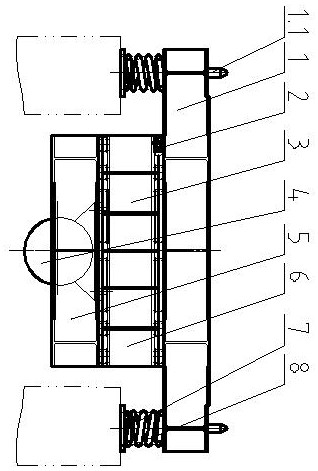

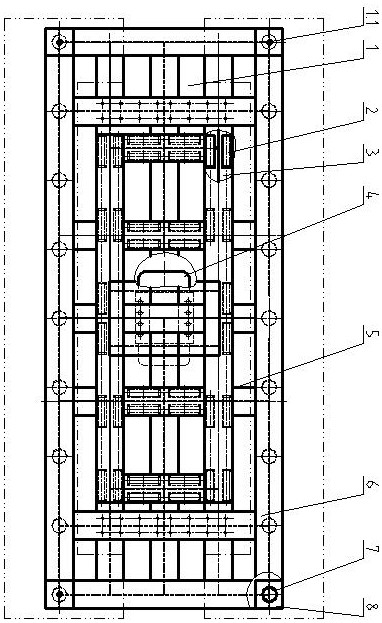

[0016] control Figure 1~3 , a novel container vibrating table of the present invention is composed of a vibrating table 1, a rubber spring 2, a balance body 3, a vibrating motor 4, a pressure plate 5, a side plate 6, a damping spring 7 and a spring bottom 8, and the vibrating table 1 is Positioning pins 1.1 are respectively provided at the four corner grooves, the bottom of the vibration table 1 is connected to the top of the rubber spring 2, the bottom of the rubber spring 2 is connected to the top of the balance body 3, the bottom of the balance body 3 is connected to the side of the rubber spring 2, and the vibration motor 4 is installed on In the middle position under the balance body 3, the other side of the rubber spring 2 under the balance body 3 is connected to the pressure plate 5, and both ends of the pressure plate 5 are connected to the vibrating table 1 through the side plate 6, and vibration damping springs are evenly arranged on both sides of the vibrating table...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com