Automatic discharging printing machine for environment-friendly bag processing

A technology of automatic unloading and environmental protection bags, applied to printing machines, rotary printing machines, printing, etc., can solve the problems of inconsistent pattern positions, low work efficiency, troublesome operation, etc., and achieve consistent pattern positions, convenient operation, and high work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

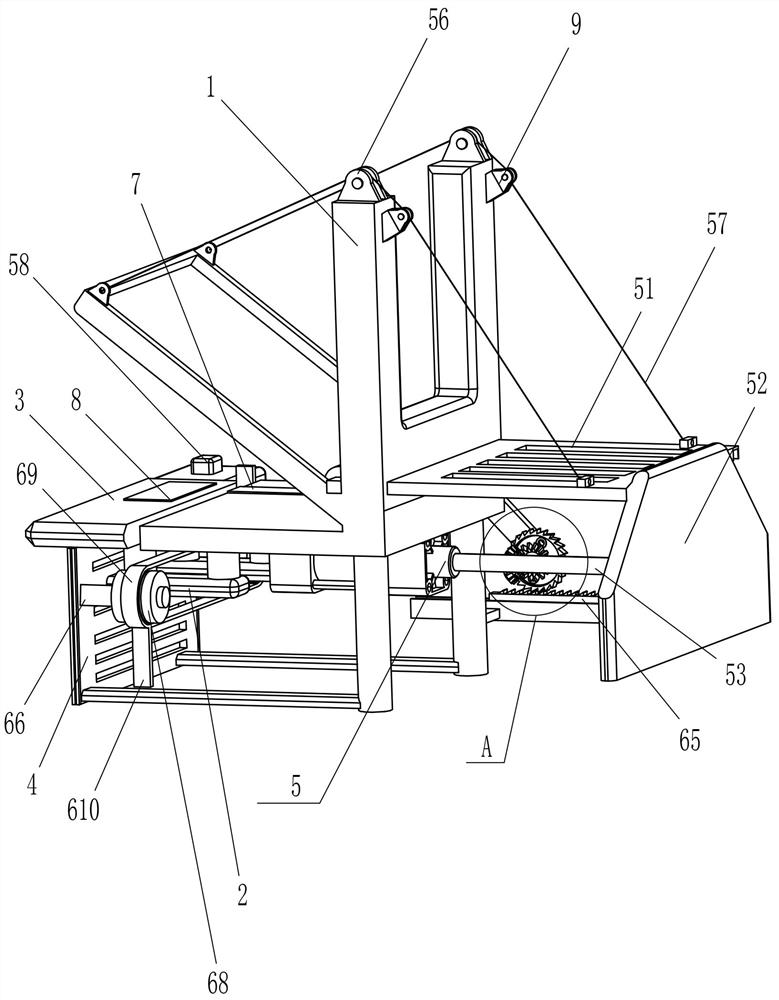

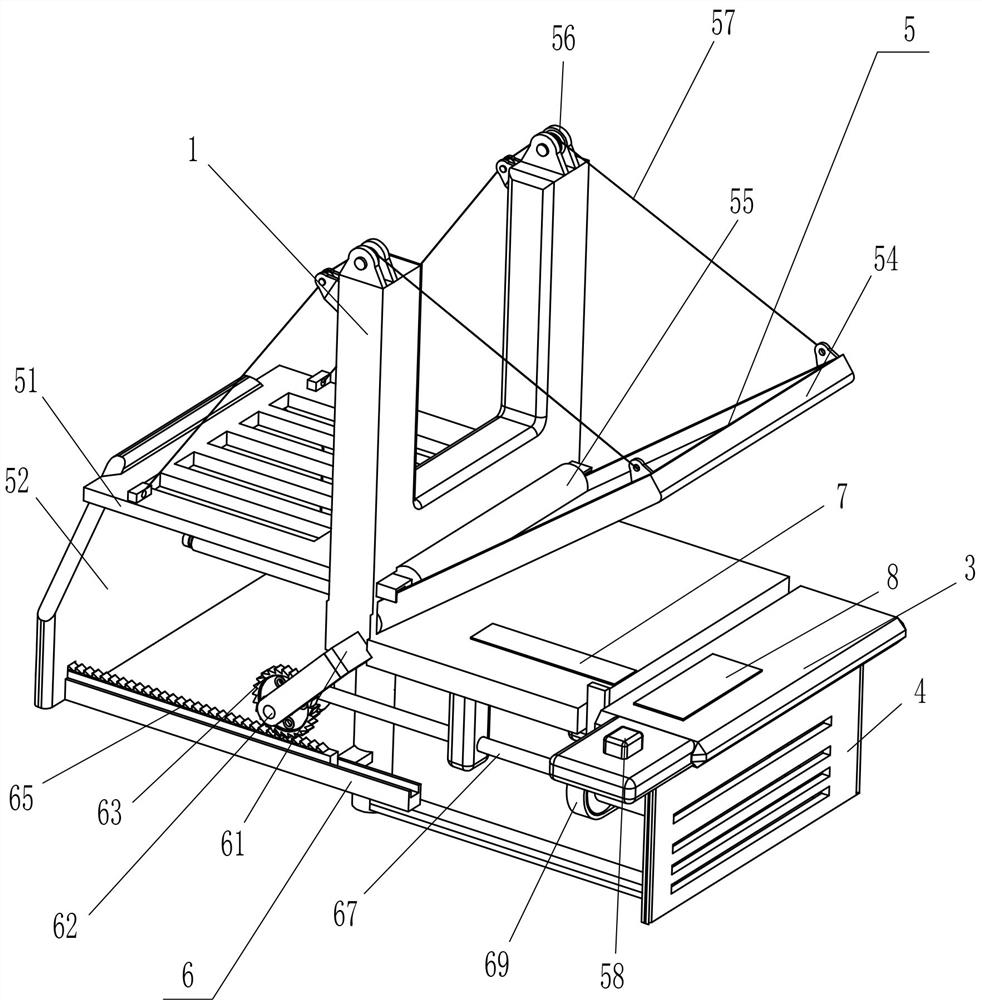

[0021] An automatic unloading printing machine for environmental protection bag processing, such as figure 1 and figure 2 As shown, it includes an L-shaped plate 1, a u-shaped fixed block 2, an operation plate 3, a support plate 4 and a printing mechanism 5, and the front and rear sides of the outer bottom of the L-shaped plate 1 are symmetrically fixed with a u-shaped fixed block 2, and the front and rear sides An operation panel 3 is affixed between the top of the right side of the u-shaped fixed block 2, a support plate 4 is affixed to the bottom of the operation panel 3, and a printing mechanism 5 is arranged between the left part of the L-shaped plate 1.

[0022] The printing mechanism 5 includes a multi-slot plate 51, a fixed plate 52, a cylinder 53, a printing plate 54, a cylinder 55, a wire pulley 56, a pull cord 57 and a button 58, and the lower part of the left side of the L-shaped plate 1 slides through the multi-slot plate 51, the left side of the multi-slot plat...

Embodiment 2

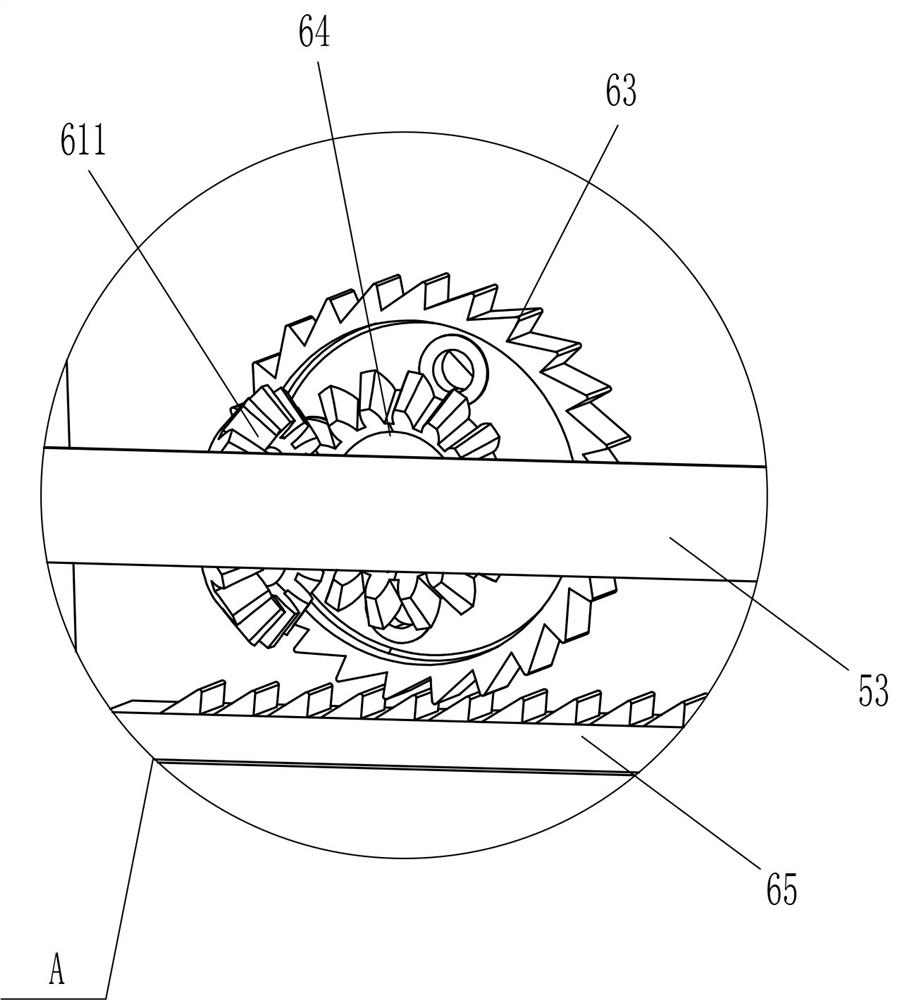

[0026] On the basis of Example 1, such as Figure 1-Figure 3 As shown, transmission mechanism 6 is also included, and transmission mechanism 6 includes L-shaped bar 61, fixed rod 62, ratchet 63, first bevel gear 64, ratchet bar 65, transmission shaft 67, cross bar 66, pulley 68, flat belt 69. The pushing block 610 and the second bevel gear 611, the L-shaped bar 61 is fixedly connected to the left side of the lower part of the front side of the L-shaped plate 1, and the lower part of the L-shaped bar 61 is rotatably connected to the fixed rod 62, and the middle part of the fixed rod 62 is fixed in the circumferential direction. A ratchet 63 is connected, a first bevel gear 64 is fixedly connected to the rear of the fixed rod 62 in the circumferential direction, a ratchet strip 65 is fixedly connected to the lower front side of the right side of the fixed plate 52, and the ratchet strip 65 and the ratchet 63 are meshed. There is a transmission shaft 67 in the middle of the front...

Embodiment 3

[0029] On the basis of embodiment 1 and embodiment 2, such as figure 1 and figure 2 As shown, a first rubber block 7 and a second rubber block 8 are also included, the first rubber block 7 is affixed to the front side of the inner bottom of the L-shaped plate 1 , and the second rubber block 8 is affixed to the front side of the top of the operation panel 3 .

[0030] Also include guide wheel 9, L-shaped plate 1 outer left side top, front and rear sides are all fixedly connected with guide wheel 9, and guide wheel 9 contacts and cooperates with stay cord 57.

[0031] When the environmental protection bag is placed on the L-shaped board 1, the environmental protection bag is contacted with the first rubber block 7 and the second rubber block 8, and the first rubber block 7 and the second rubber block 8 limit the environmental protection bag, so that the The position of the environmental protection bag is consistent every time, which makes the position of the printed pattern co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com