Main shaft transmission arrangement structure of vertical lathe

A technology of spindle drive and layout structure, which is applied in the direction of driving devices, turning equipment, turning equipment, etc., can solve the problems of complicated design of the working turntable, troublesome precision adjustment, and large space occupation, and achieves simple design of the turntable, compact structure, and low cost. The effect of installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

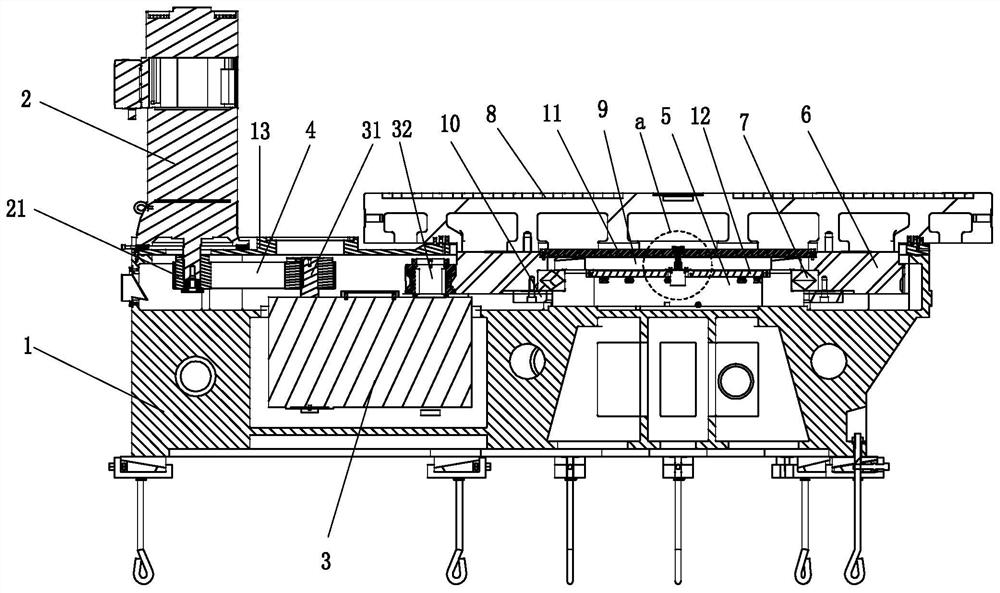

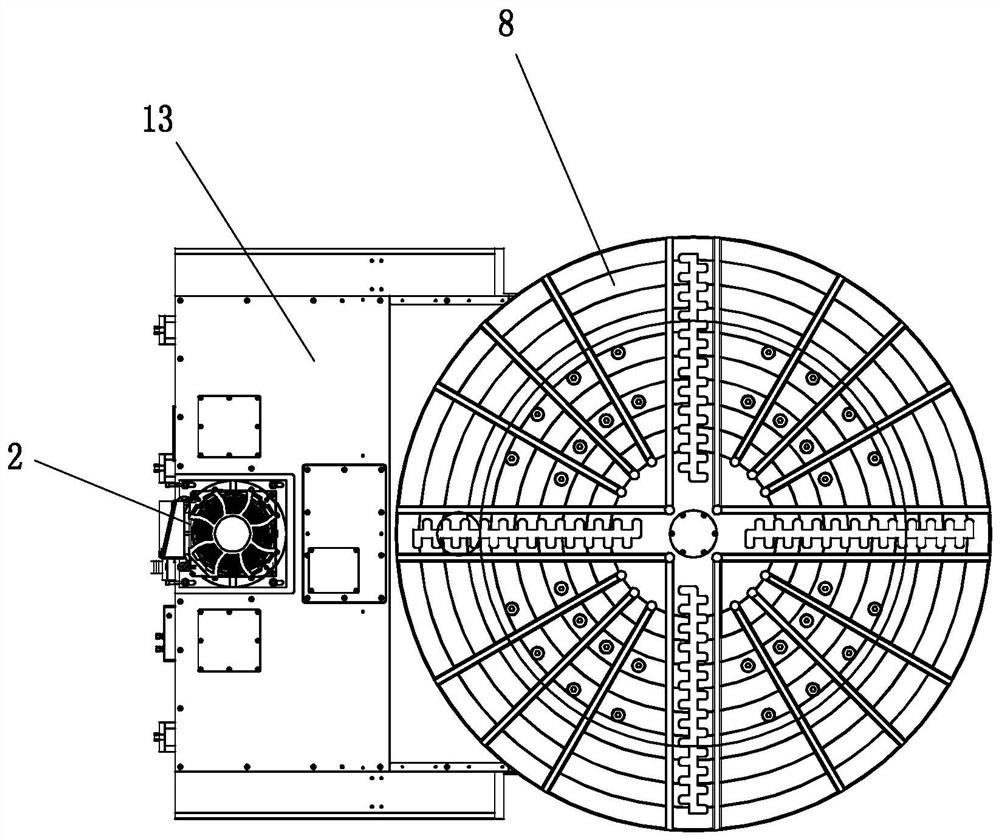

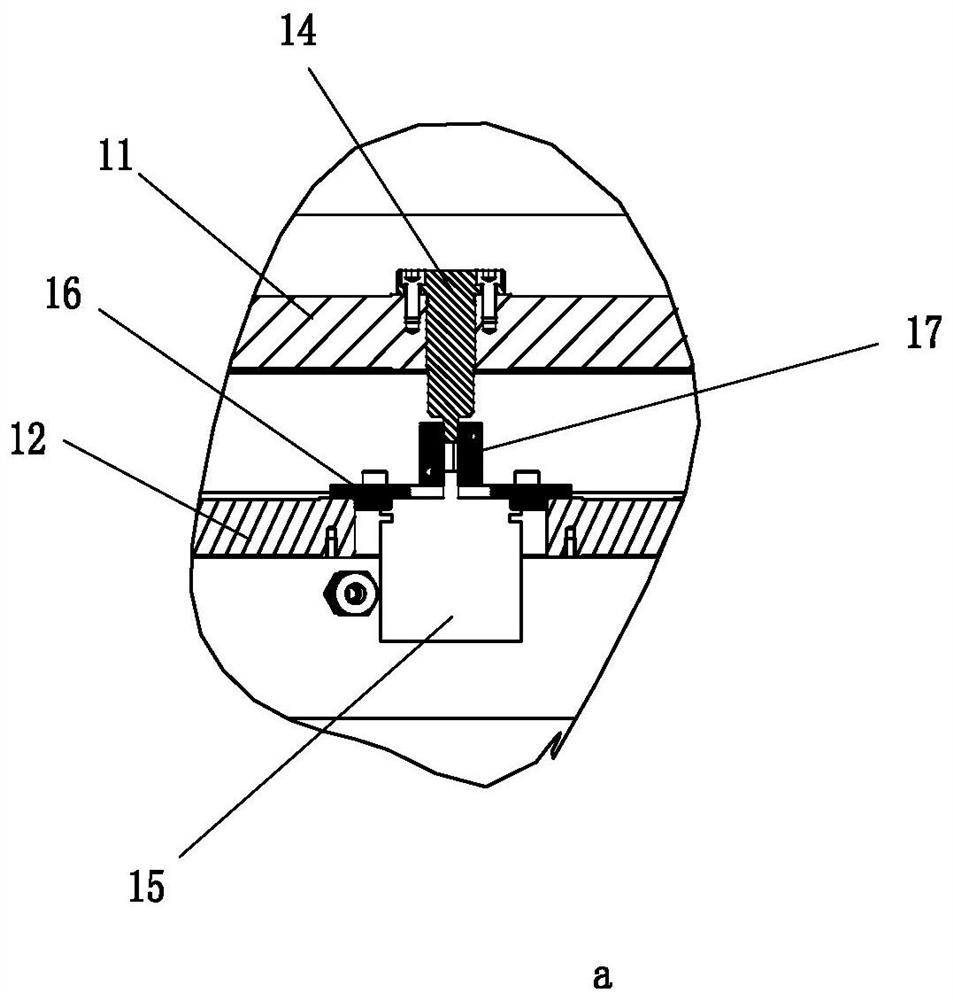

[0021] Such as Figure 1-Figure 3 As shown, the present invention comprises motor 2, reduction box 3, main shaft 5 and transmission ring gear 6, and motor 2 is installed by motor mounting plate, and the motor shaft 21 of motor 2 faces downward, and the speed reduction box installation groove is formed on the lathe bed 1, and reduction box The input shaft 31 and the output shaft 32 of 3 face upward and face the motor shaft 21, the input shaft 31 of the reduction box 3 and the motor shaft 21 are connected through the pulley and the belt 4; the main shaft 5 is supported and installed in the transmission ring gear 6 , The output shaft 32 of the reduction box 3 is set with a gear, and the outer peripheral portion of the transmission ring gear 6 is meshed with the gear. A workbench 8 is arranged on the top end surface of the transmission ring gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com