Automatic box locking device and method for sand-lined iron mold casting pouring trolley

A technology of sand-covered casting of iron molds and pouring trolleys, which is applied in the field of machinery, can solve the problems of labor-intensive moving of boxes and cards, and achieve the effects of low production costs, reduced casting waste, and simple and reasonable overall structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0037] Example.

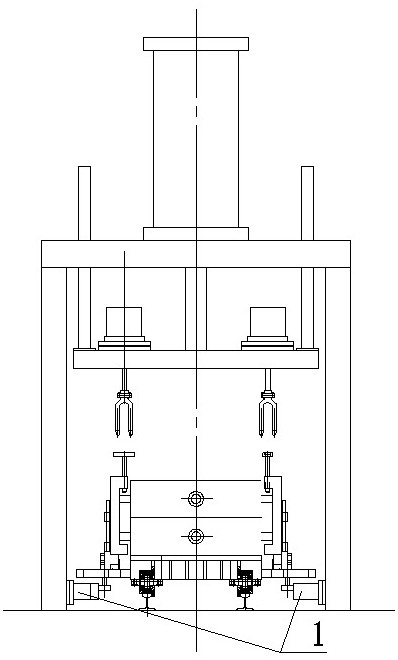

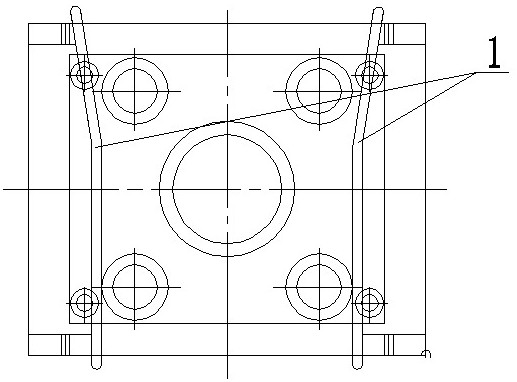

[0038] see Figure 1 to Figure 17 , the present embodiment is used for the automatic lock box device of the trolley for sand-covered iron casting, which includes a trolley box card closing guide plate 1, an upper beam 2, a column 6, a lifting hydraulic cylinder 3, a lifting moving beam 5 and a plurality of box card locking The tightening device 4 is fixed to the upper beam 2 above the column 6, the column 6 is set on the ground on both sides of the pouring trolley, the lifting hydraulic cylinder 3 is fixed on the upper beam 2, and the locking and tightening devices 4 of multiple box clamps are connected to each other. Installed on the lifting beam 5, the piston rod of the lifting hydraulic cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com