Active metal powder transfer oxygen-isolation screening system

A technology of active metal and powder, which is applied in the field of active metal powder transfer and oxygen barrier screening system, which can solve the problems of being unable to provide sieving powder and strictly ensuring the water and oxygen content of the sieving machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

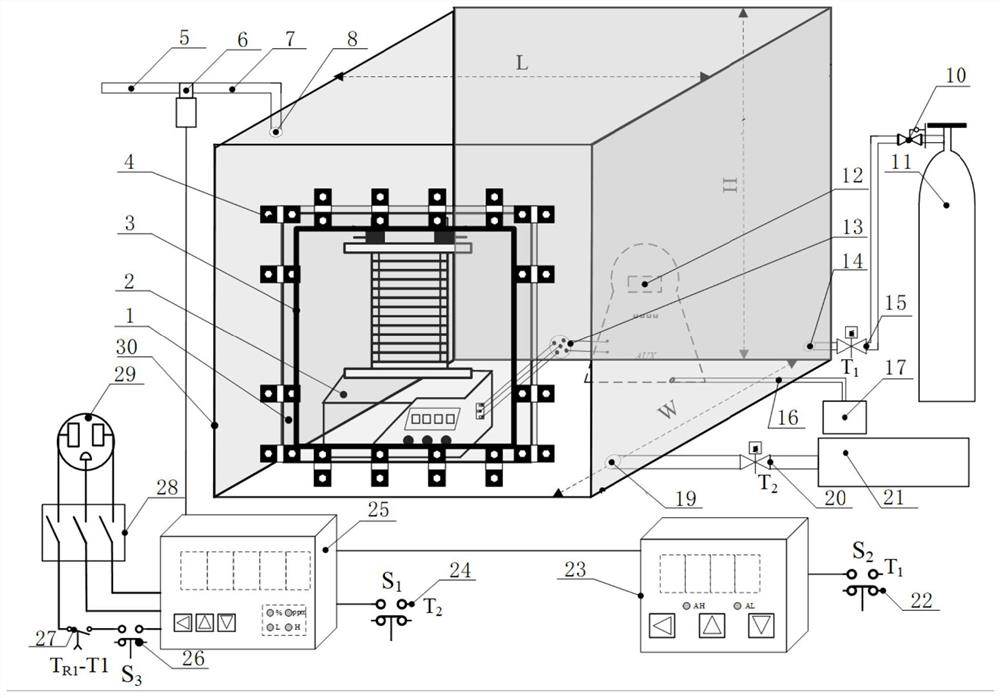

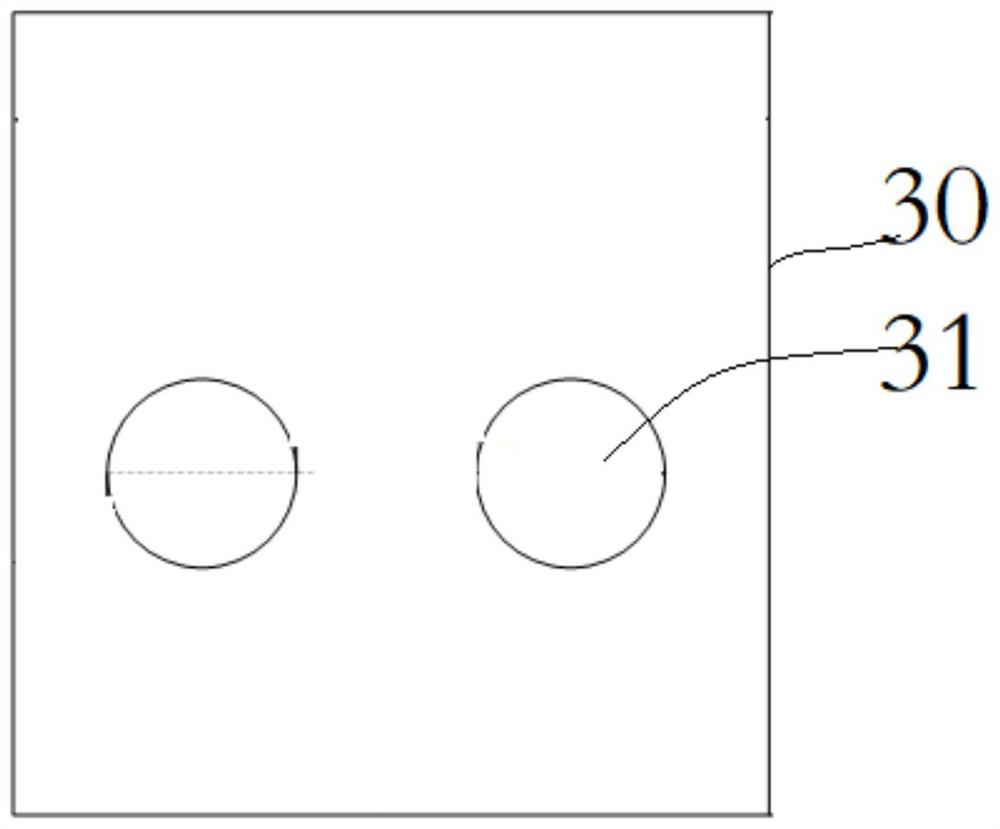

[0038] According to the actual production needs, this application sets up the corresponding isolation box connection and panel size, L=800mm, H=850mm, and the isolation box uses a special adhesive to stick acrylic blocks with a thickness of 10mm and a length of 60mm in sections Shaped strips, the ring cloth is inside, and the outer part is treated with special sealant. The length of the part extending from the edge of the door side is 30mm. The selected silicone D-shaped sealing ring 3 is used as the edge sealing strip and the ring cloth is on the outside. The part has a width of 10mm, a height of 8mm, and a thickness of 1.5mm, and the sealing ring is installed in the middle of the overhanging part.

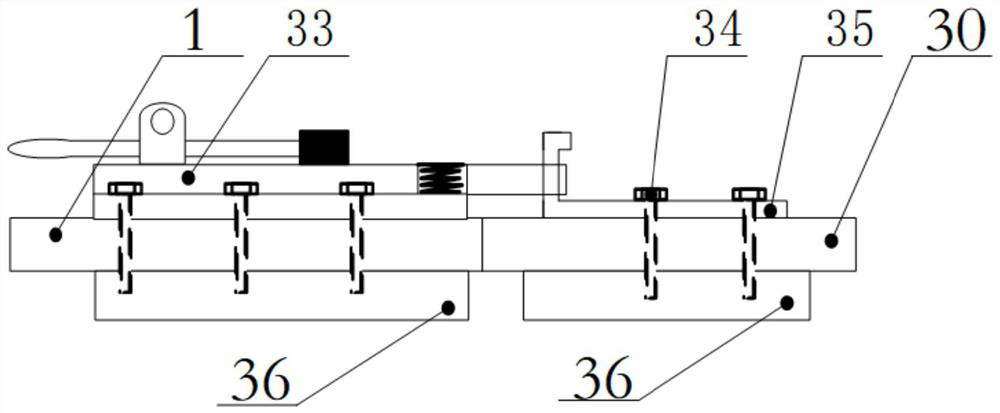

[0039] In order to securely install the fast deadbolt clamp, the inside of the isolation box 30 installed at the buckle end 35 is bonded to an acrylic plate with a length of 50 mm, a width of 30 mm, and a thickness of 8 mm through an adhesive, and the side installed at the clamp e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com