A vertical cavity surface emitting laser containing cadmium sulfide/zinc sulfide core-shell quantum dots and its manufacturing method

A technology of vertical cavity surface emission and core-shell quantum dots, which is applied in the direction of lasers, phonon exciters, laser components, etc., can solve the problem that the coupling between colloidal quantum dots and planar cavity is not well realized, and the expansion coefficient is quite different , It is difficult to obtain high quality factor resonant cavity and other problems, to achieve high stability, high quality factor and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

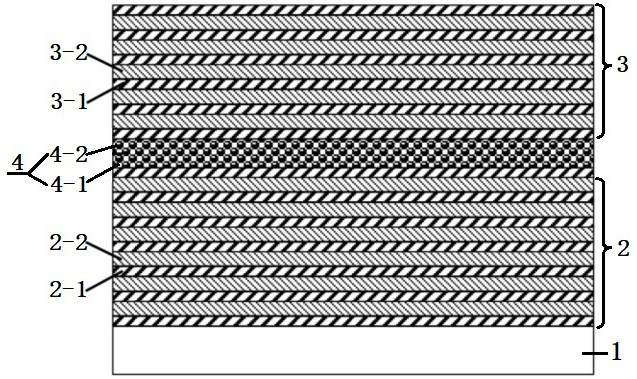

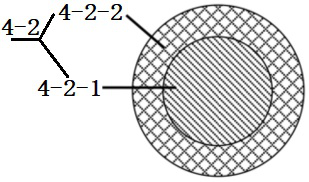

[0027] The present invention designs a vertical cavity surface emitting laser containing cadmium sulfide / zinc sulfide core-shell quantum dots. In practical applications, such as figure 1 As shown, it specifically includes a substrate 1, a lower high-reflective mirror 2, an upper high-reflective mirror 3, and a main silicon dioxide layer 4 containing cadmium sulfide / zinc sulfide core-shell quantum dots; wherein, the lower high-reflective mirror 2 is fixedly covered. On the upper surface of the substrate 1, the main silicon dioxide layer 4 is fixedly covered and arranged on the upper surface of the lower high reflection mirror 2, and the ultra-low For the optical gain of the threshold value, the upper mirror 3 is fixedly covered and arranged on the upper surface of the main silicon dioxide layer 4 . In practical applicatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quantum dot | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com