Transparent conductive film and manufacturing method thereof

A technology of a transparent conductive film and a manufacturing method, which is applied in the manufacture of cables/conductors, conductive layers on insulating carriers, and equipment for manufacturing conductive/semi-conductive layers, etc., can solve the problem of low product quality and poor bonding effect. , the difficulty of fitting, etc., to achieve the effect of improving conductivity, reducing thickness and processing difficulty, and facilitating fitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

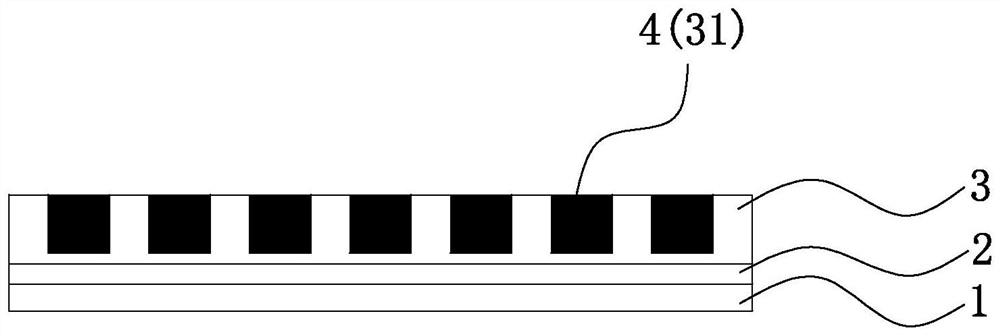

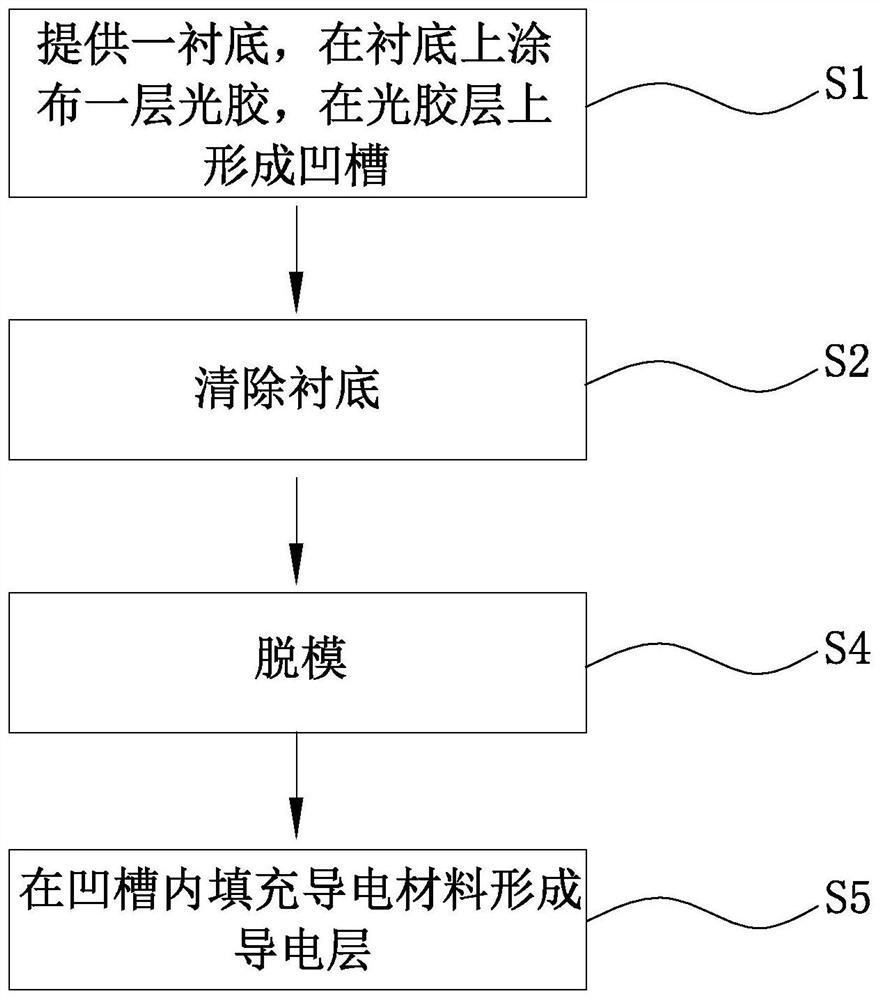

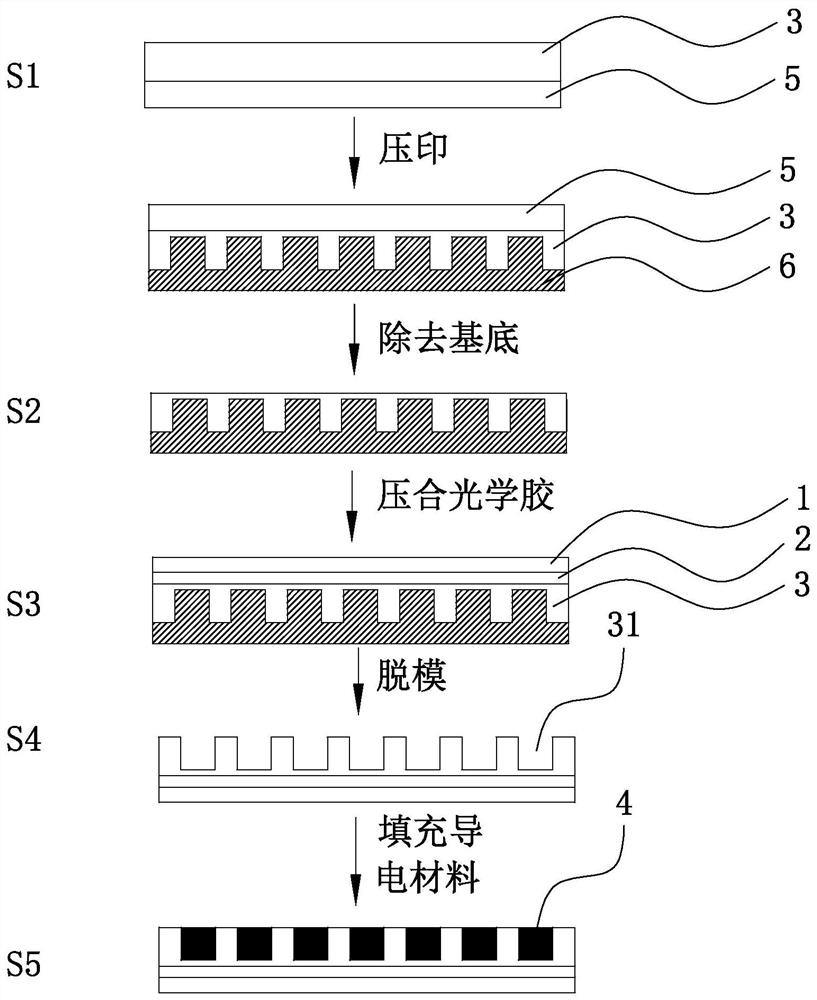

[0035] Please refer to Figure 2 to Figure 3 , the method for making the transparent conductive film provided in the first embodiment of the present invention is used to make the above transparent conductive film, the method comprising:

[0036] S1: Provide a substrate 5, coat a layer of photoresist on the substrate 5, and form grooves 31 on the photoresist layer 3;

[0037] S2: remove the substrate 5;

[0038] S3: providing an optical adhesive film, including an optical adhesive layer 2 and a base film 1, and laminating the optical adhesive film on the optical adhesive layer 3;

[0039] S5: filling the groove 31 with a conductive material to form the conductive layer 4 .

[0040] In this method, the photoresist is UV photoresist.

[0041] In step S1: use the mold 6 to emboss on the photoresist, so that the mold 6 and the photoresist are pasted together. A photoresist layer 3 with grooves 31 is formed after being cured by UV light.

[0042] In step S2 : manually separate ...

no. 2 example

[0046] The difference between the transparent conductive film method provided by the second embodiment of the present invention and the above-mentioned first embodiment is that in this embodiment, the optical adhesive is directly coated on the optical adhesive film.

[0047] Specifically, please refer to Figure 4 , the transparent conductive film method provided by the second embodiment of the present invention is used to make the above transparent conductive film, the method includes:

[0048] S7: providing an optical adhesive film, including an optical adhesive layer and a base film, and preparing an optical adhesive layer with grooves on the optical adhesive film;

[0049] S8: filling the groove with a conductive material to form a conductive layer;

[0050] In step S7: Firstly, by coating, a layer of optical adhesive is coated on the surface of the optical adhesive layer away from the base film to form an optical adhesive layer. Then use the mold to emboss on the photor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com