Lightweight optimization method for aviation corrugated pipe adhesive film structure

An optimization method and bellows technology, applied in design optimization/simulation, image data processing, special data processing applications, etc., can solve problems such as not mentioning the addition of margins, and achieve the effect of improving material utilization and ensuring stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

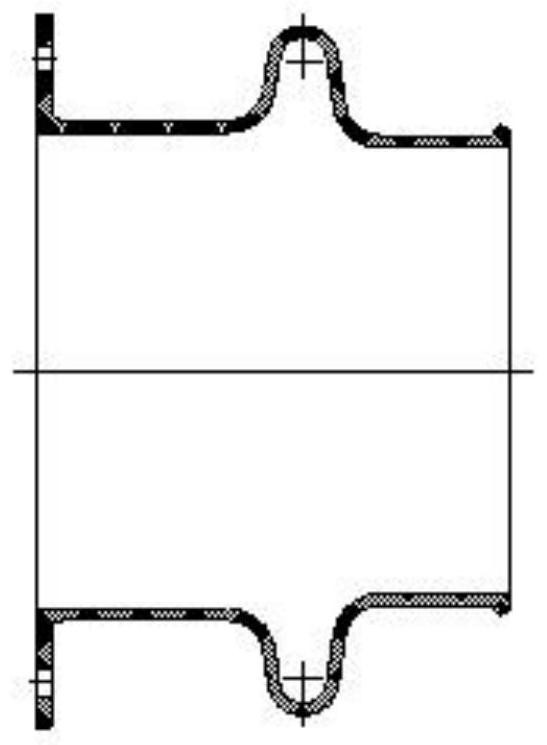

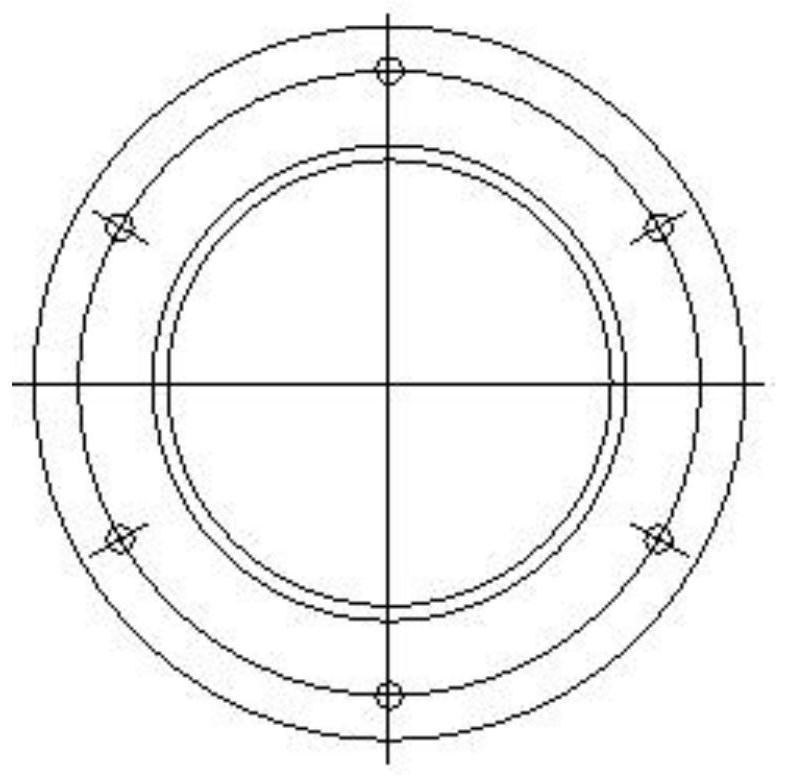

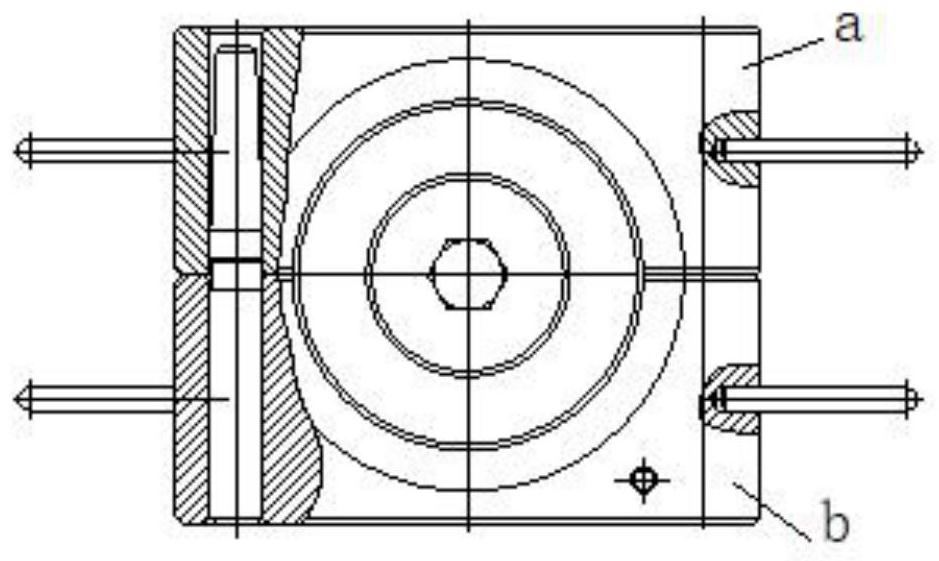

[0032] Such as Figure 1 to Figure 6 As shown, a lightweight optimization method for aerospace bellows film structure, the specific steps are as follows:

[0033] S1: Three-dimensional model construction: construct a three-dimensional model according to the two-dimensional drawing of the aviation rubber bellows film;

[0034] S2: Partial reconstruction and optimization of the model: the design of the film structure of the two-dimensional drawings is based on the traditional mechanical processing technology, and the difficulty of mechanical processing is considered in part of the film structure, and the fractional structure design is adopted; the metal 3D printing process can be integrated to form complex structures, Therefore, the fractional structure is integrated, reconstructed and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com