A three-chamber two-power source fully decomposed water electrolysis device and method

A technology for fully splitting water and electrolysis devices, applied in electrolysis components, electrolysis processes, electrodes, etc., can solve the problems of scarcity of precious metal materials, high energy consumption of hydrogen and oxygen, save investment and operating costs, save investment costs, and avoid unnecessary The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, the present invention will be further described.

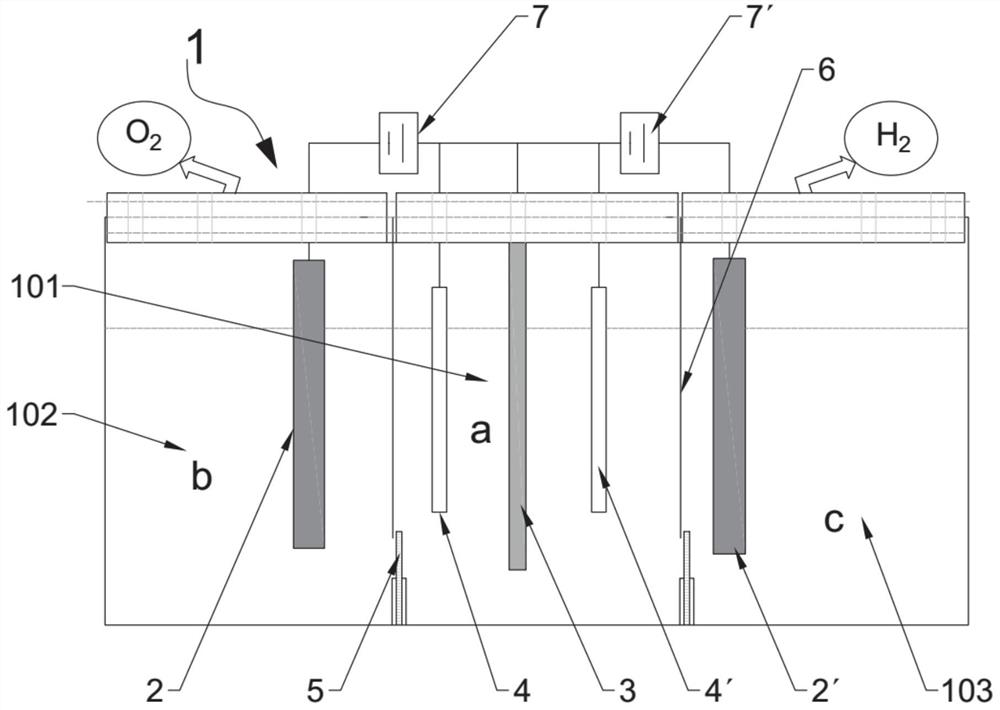

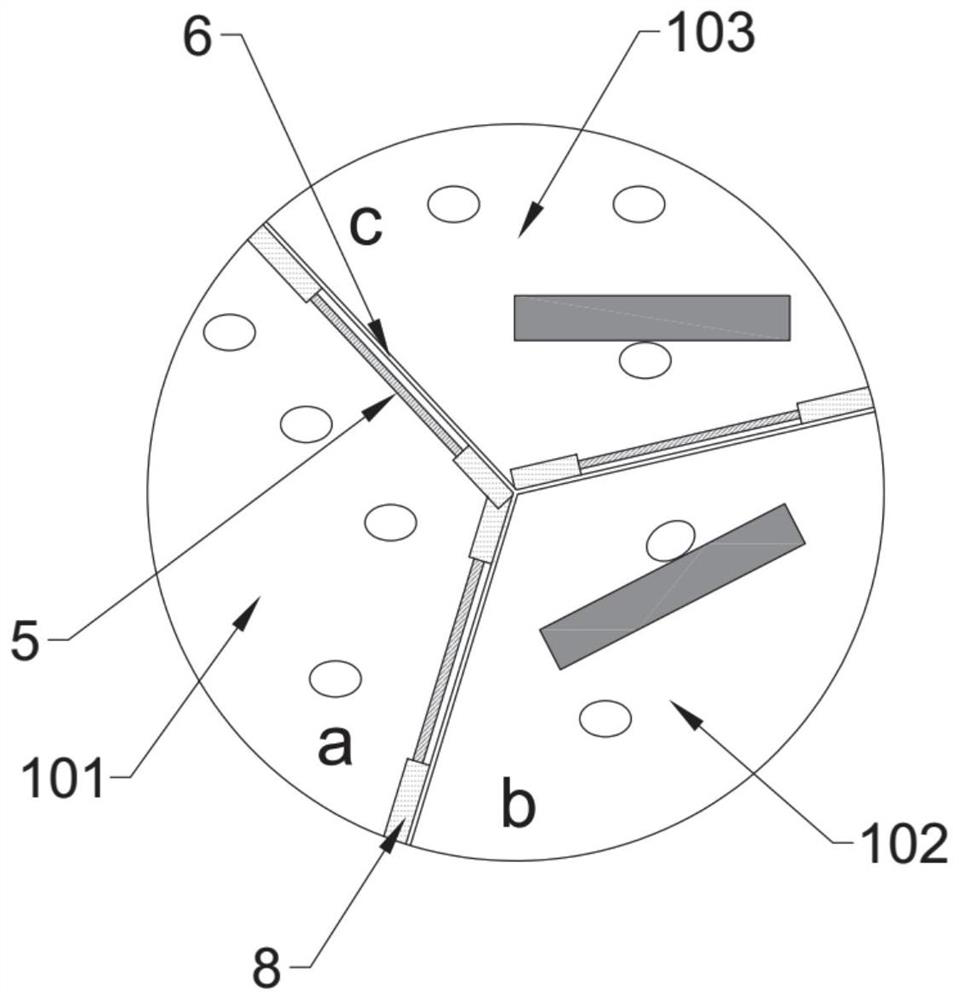

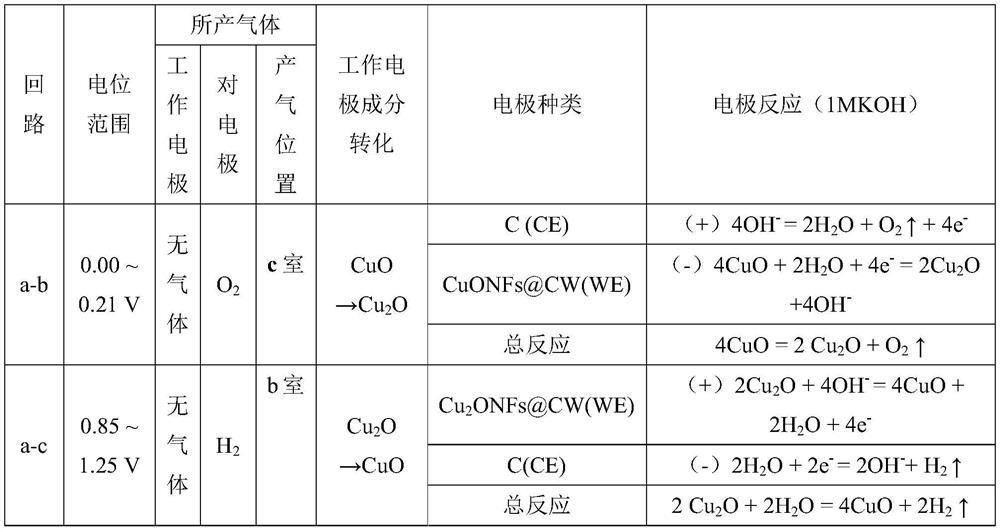

[0024] A method for fully decomposing water and electrolysis with three chambers and two power sources, the method includes the following steps using devices such as figure 1 and figure 2 As shown, it includes a cylindrical electrolytic cell 1, two electrochemical workstations 7 and 7′ placed outside the cylindrical electrolytic cell 1, two counter electrodes 2 and 2′ placed in the cylindrical electrolytic cell 1, a working electrode 3, two reference electrodes Than electrodes 4 and 4ˊ.

[0025] The structure of cylindrical electrolytic cell 1 is as follows:

[0026] (1) Cylindrical electrolytic cell 1 is mainly made of a cylinder of glass or plastic material. In this embodiment, cylindrical electrolytic cell 1 is 0.2 meters high and the diameter of the bottom is 0.2 meters. The bottom and side of cylindrical electrolytic cell 1 are a Overall, good airtightness;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com