Athermalization laser emission lens

A laser emission, athermalization technology, applied in optics, optical components, instruments, etc., can solve problems such as the decrease of ranging ability or damage ability, and increase the control accuracy of the focusing structure, so as to reduce the motion accuracy and control accuracy, reduce Motion accuracy and control accuracy requirements, the effect of less material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

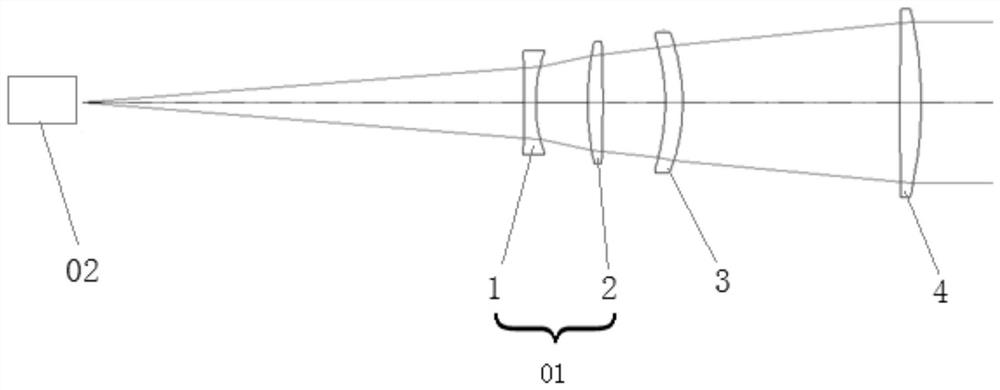

[0034] Such as figure 1 As shown, an athermalized laser emitting lens includes an optical system located on the outgoing light path of the laser 02. The optical system adopts a four-separated transmission structure. The optical system includes a fixed mirror group 01 arranged coaxially along the outgoing beam direction of the laser 02. , the third lens 3 and the fourth lens 4; the fixed lens group 01 includes the first lens 1 and the second lens 2 which are coaxially arranged in sequence along the light transmission direction, the first lens 1 is a biconcave lens with negative refractive power, and the second The lens 2 is a double-convex lens with positive refractive power; the third lens 3 is a meniscus lens with positive refractive power bent toward the side of the laser 02; the fourth lens 4 is a double-convex lens ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com