Micro-lens device and manufacturing method thereof

A micro-lens, transparent technology, applied in lens, optics, instruments, etc., can solve the problems of limited use of molds, damage to molds and plastic plates, and high cost of mold opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

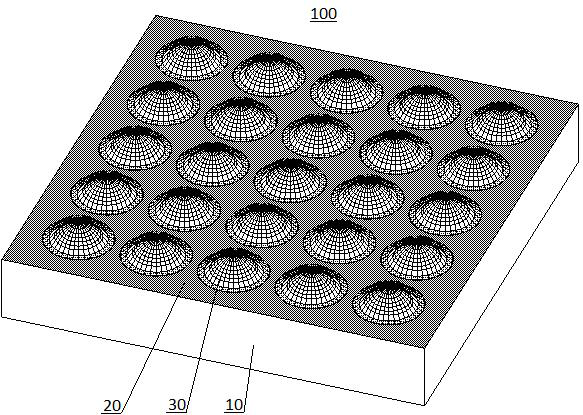

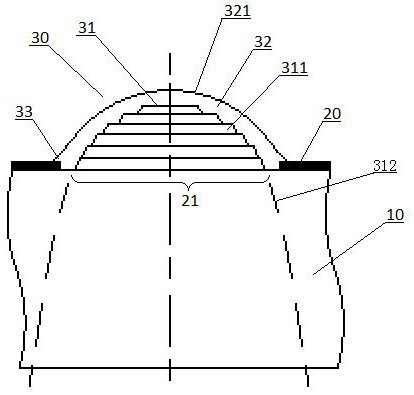

[0031] The microlens device 100 includes a transparent glass substrate 10 with a thickness of 0.4 mm. One surface of the transparent glass substrate 10 is provided with a shielding layer 20 and a microlens array composed of a large number of microlens units 30 .

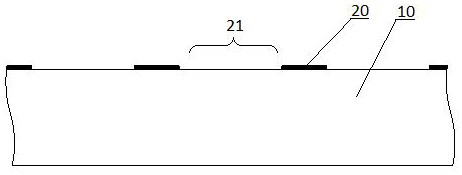

[0032] The shielding layer 20 is a patterned black photosensitive resin layer (light transmittance less than 10%), which forms a large number of circular light-transmitting windows 21 through patterning of yellow light processes such as exposure and development, and the light-transmitting windows 21 are located in each microlens unit 30 bottom.

[0033] The micro-lens unit 30 is disposed on each light-transmitting window 21 , which is a micro-convex lens with a diameter less than 0.2 mm. Each microlens unit 30 includes a transparent support portion 31 and a smooth portion 32. The support portion 31 is formed by overlapping circular transparent resin sheets 311 with the same refractive index. The thickness of the resi...

Embodiment 2

[0043] On the basis of Embodiment 1, the support part is changed to be formed by overlapping a plurality of strip-shaped resin sheets 311', and the width of the resin sheet 311' decreases layer by layer according to the negative parabolic function relationship from bottom to top, thus forming The microlens device 100' includes a plurality of microlens units 30' having lenticular functions, which constitutes the second embodiment of the present invention.

Embodiment 3

[0045] On the basis of the second embodiment, the width of the resin sheet 311' is changed from bottom to top to decrease layer by layer according to a linear function relationship, and thus the formed microlens device 100" includes a plurality of microlens units 30" with prism functions , then constitute the third embodiment of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com