Liquid level control system

A liquid level control and liquid level technology, applied in the direction of liquid level control, control/regulation system, piping system, etc., can solve the problems of unreasonable control, voltage stabilization, dust removal, water collection and drainage of the system structure design, and achieve the overall structure The design is compact and reliable, the effect of compact structure and strong reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

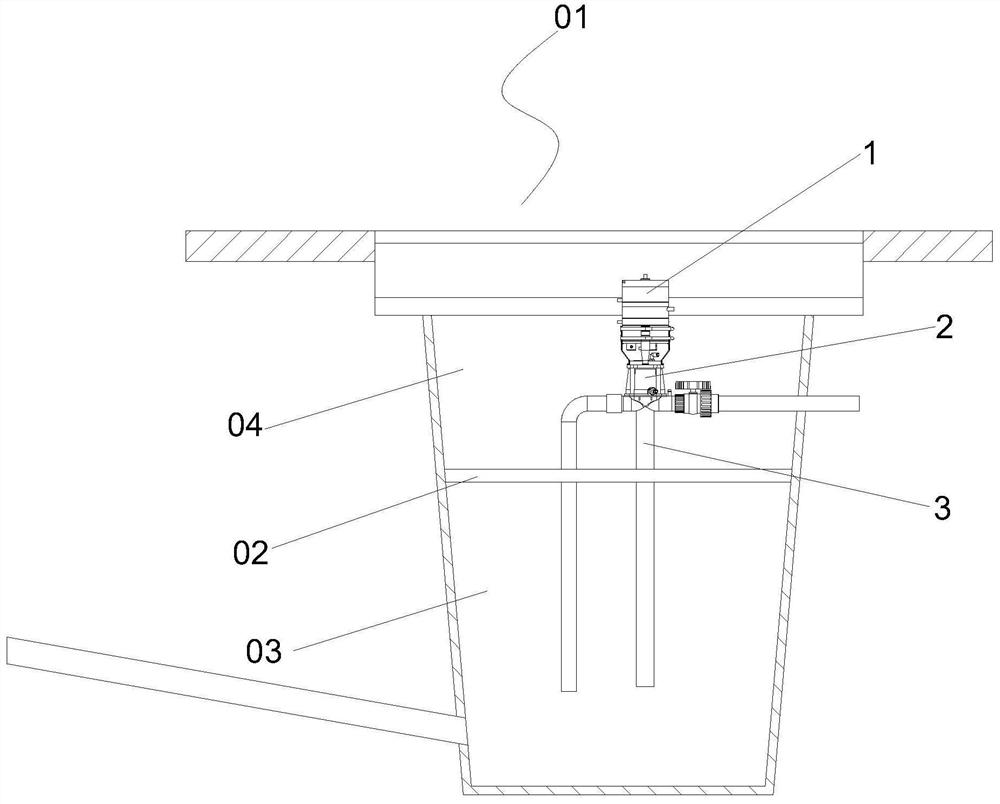

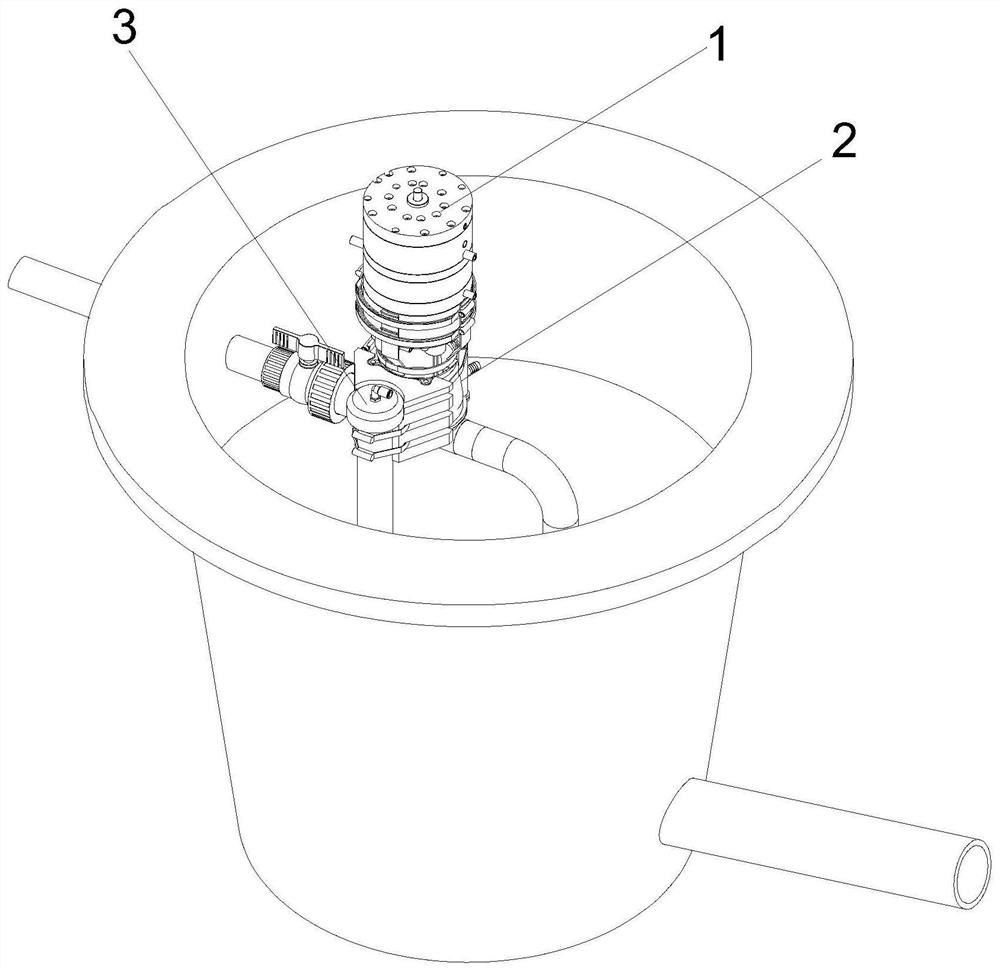

[0085] like figure 1 As shown, a liquid level control system is applied to the technical field of continuous vacuum sewage collection, temporary storage and periodic transportation system, that is, the technical field of vacuum well. The vacuum well 01 is installed below the ground, and a partition 02 is arranged inside it Divide the inside of the vacuum well 01 into sewage chamber 03 and equipment chamber 04. The liquid level control system is installed in the equipment chamber 04. Pneumatic controller 1 for opening and closing of vacuum blowdown valve 2; figure 2 As shown, the vacuum drain valve 2, the liquid level pressure sensor 3 and the pneumatic controller 1 can be arranged side by side along the horizontal direction and fixedly connected by a hoop; image 3 As shown, the vacuum blowdown valve 2 and the pneumatic controller 1 can be set up and down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com