Unlimited-level full-bore staged fracturing sand prevention pipe column and production method thereof

A segmented fracturing and full-bore technology, which is applied in the direction of drill pipe, casing, earthwork drilling and production, etc., can solve the problem that the sand control string cannot be lowered, the number of fracturing layers is limited, and the size of the sand control string is small and other issues to achieve the effect of shortening the life cycle and increasing development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technology and method of the present invention will be described in detail below in conjunction with the examples and accompanying drawings. The following examples and accompanying drawings are used to illustrate the composition of the present invention, but are not intended to limit the scope of the present invention.

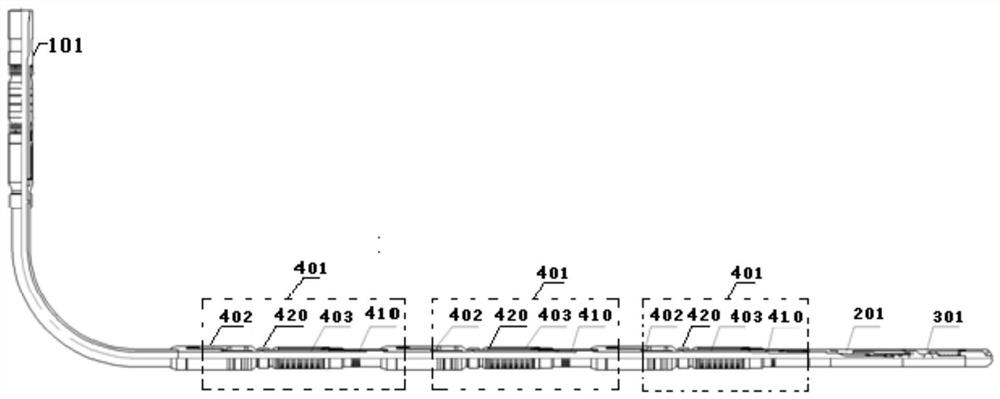

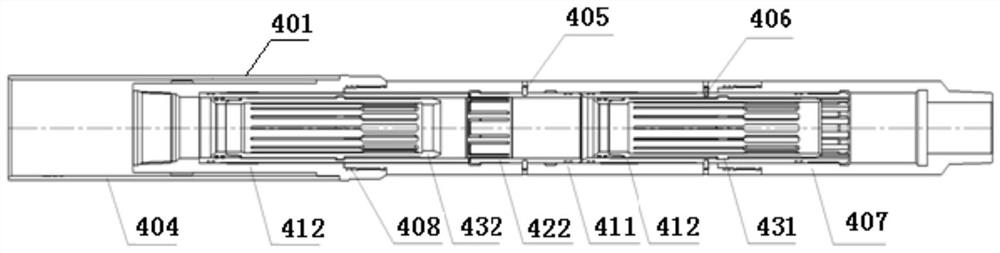

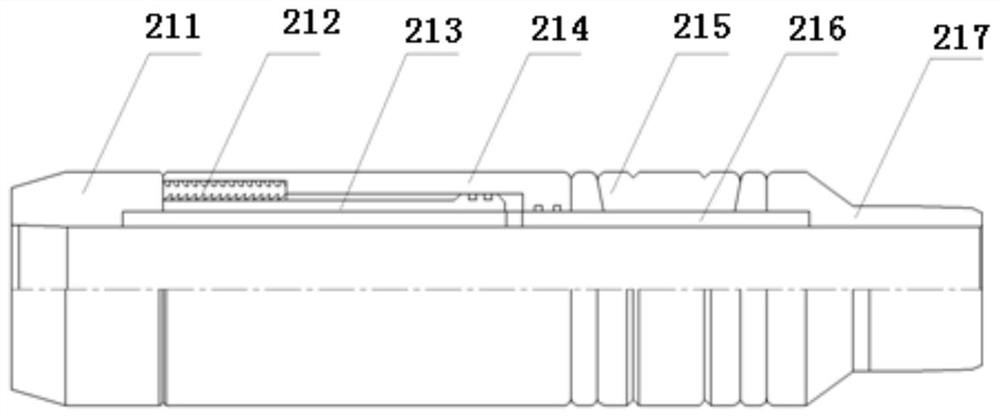

[0027] Such as figure 1 As shown, the present invention provides an infinite-stage full-diameter staged fracturing sand control string, which includes a suspended fracturing packer 101, a wellbore isolation valve 201, and a floating shoe 301; the suspended fracturing pack Between the device 101 and the wellbore isolation valve 301, there is at least three layers of staged fracturing sand control dual-stage mechanism 401; the staged fracturing sand control dual-stage mechanism 401 includes an open hole fracturing packer 402, a The kit 410, the production kit 420, the uncasing part 430 and the double-stage screen 403 are composed; wherein: the fractur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com