Gear blackening frame for machining

A technology of mechanical processing and gears, which is applied in the field of blackening racks, can solve problems such as laboriousness, and achieve comprehensive and uniform blackening with good effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

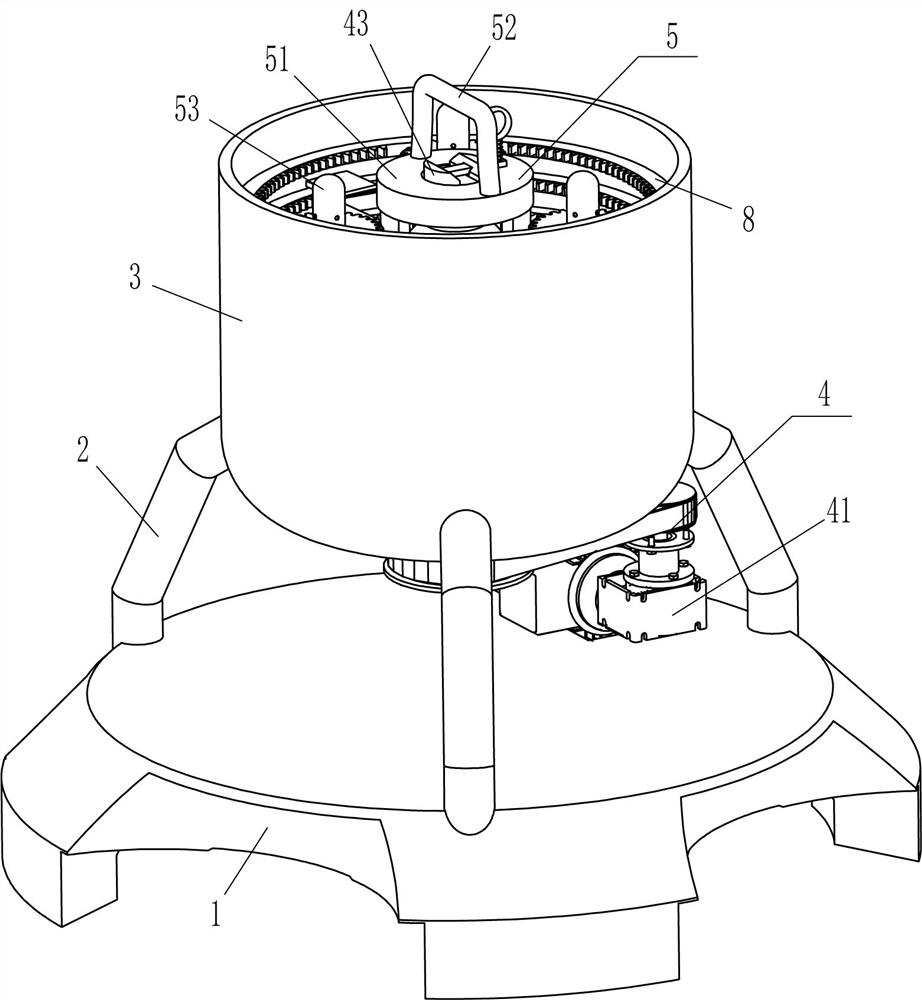

[0025] A gear blackening frame for mechanical processing, such as Figure 1-Figure 3 As shown, it includes a base 1, a pole 2, a charging cylinder 3, a rotating mechanism 4, a discharging mechanism 5 and a push plate 6, and the top of the base 1 is fixedly connected with three poles 2 at uniform intervals in the circumferential direction, and three poles 2 A charging cylinder 3 is fixedly connected between the top ends, a rotating mechanism 4 is arranged between the middle part of the charging cylinder 3 and the top rear side of the base 1, and a discharging mechanism 5 is placed between the rotating mechanism 4 and the middle part of the charging cylinder 3. The mechanism 5 cooperates with the rotating mechanism 4, and the inner surface of the charging cylinder 3 is fixedly connected with push plates 6 evenly spaced circumferentially, and the number of each row of push plates 6 is five.

[0026] The rotating mechanism 4 includes a decelerating motor 41, a transmission assembl...

Embodiment 2

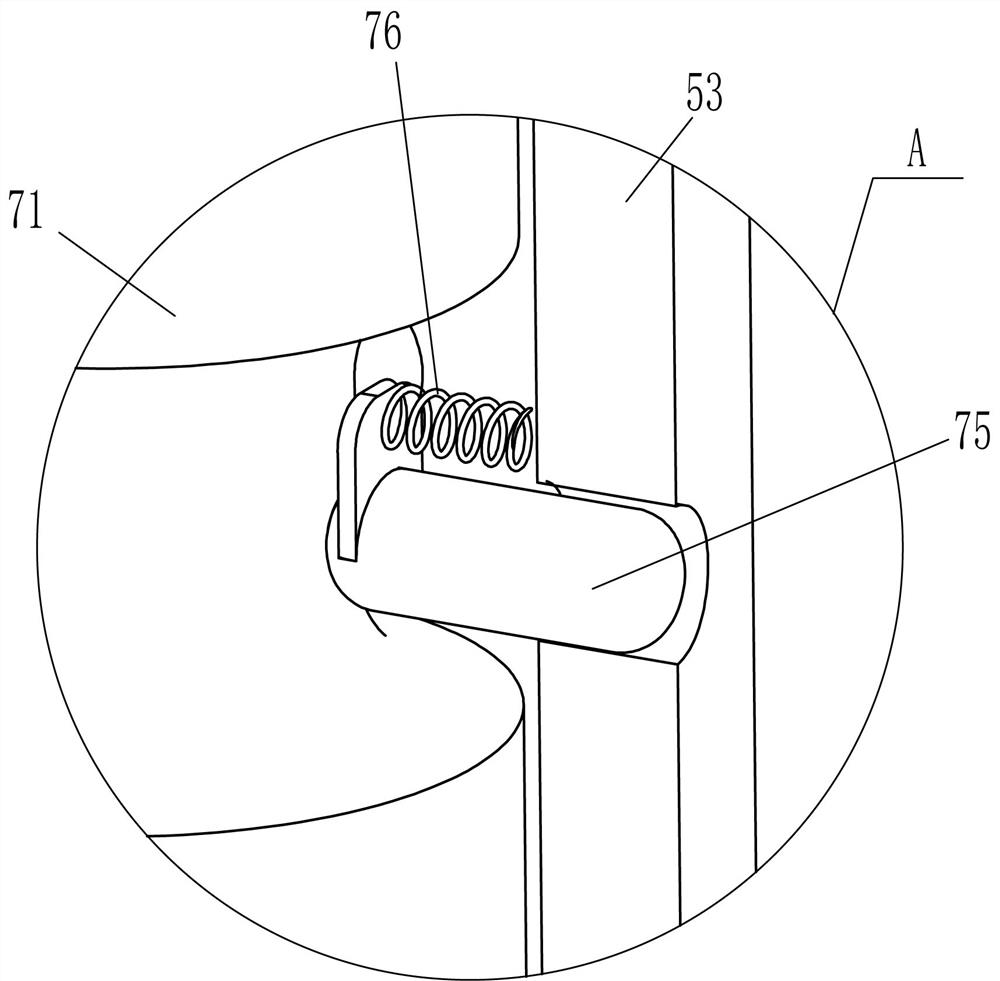

[0032] On the basis of Example 1, such as Figure 4 and Figure 5 As shown, also includes clamping mechanism 7, and clamping mechanism 7 includes driving rod 71, first spring 72, contact rod 73, three-groove fixed ring 74, clamping rod 75 and second spring 76, charging cylinder 3 middle parts There is a three-slot fixed ring 74 in the inner circumferential fixed sleeve, and the inner sliding type of the bottom of the L-shaped plate 54 is provided with a contact rod 73, and the inner end of the contact rod 73 is in contact with the three-slot fixed ring 74. Rod 71, the first spring 72 is connected between the top of the driving rod 71 and the inner top of the hollow rod 53, the bottom end of the driving rod 71 is in contact with the outer end of the contact rod 73, and the hollow rod 53 is evenly spaced in the circumferential direction. The clamping rod 75 that can be fixed to the gear, the internal end of the clamping rod 75 contacts and cooperates with the drive rod 71 , and...

Embodiment 3

[0035] On the basis of embodiment 1 and embodiment 2, such as figure 1 , figure 2 and Figure 6 As shown, an inner gear 8 is also included, five inner gears 8 are affixed to the inner surface of the charging cylinder 3 at even intervals in the circumferential direction, and the inner gears 8 and the push plates 6 are alternately arranged.

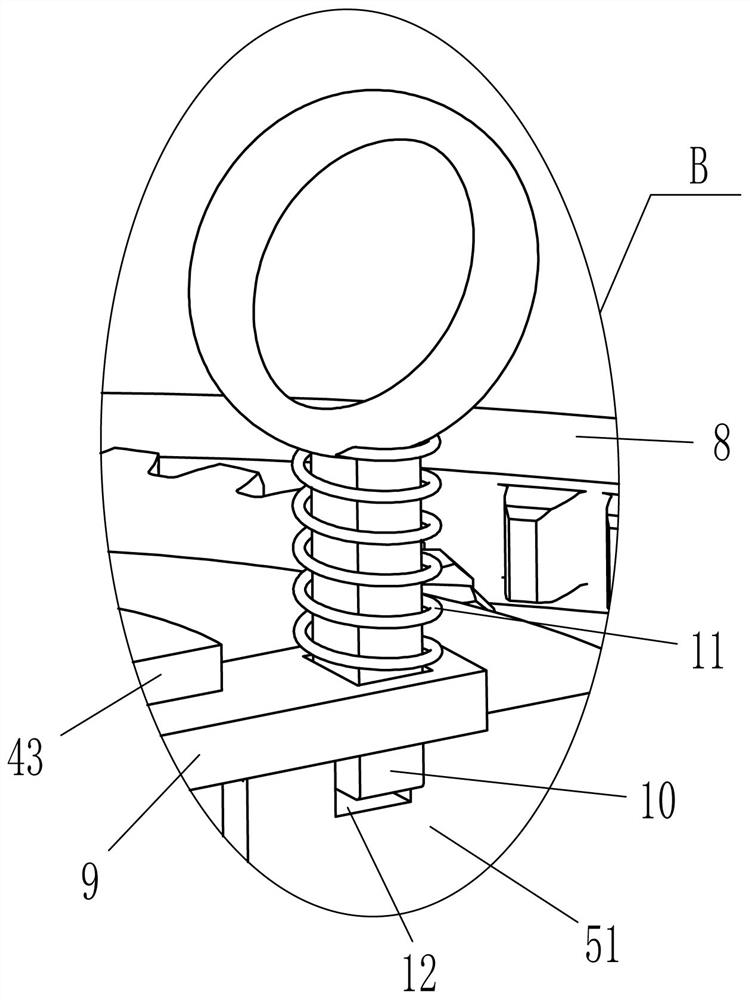

[0036] Also include clamping plate 9, pull rod 10 and the 3rd spring 11, snap ring 51 top right side has draw-in groove 12, rotating shaft 43 upper sliding type is provided with clamping plate 9, and clamping plate 9 right part sliding type wears and connects with Pull rod 10, the bottom end of pull rod 10 is located in the slot 12 to cooperate with it, and a third spring 11 is wound between the top of pull rod 10 and the right side of the top of clamp plate 9.

[0037] When the hollow rod 53 drives the gear to reverse, when the gear reverses and meshes with the ring gear 8, the ring gear 8 makes the gear rotate, and the gear rotates to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com