Preparation process of self-drainage concrete block

A concrete block and preparation technology, which is applied in the direction of manufacturing tools, ceramic molding machines, molds, etc., can solve problems such as dredging of rainwater, excessive water accumulation on the road surface, unfavorable road surface cleaning, etc., and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

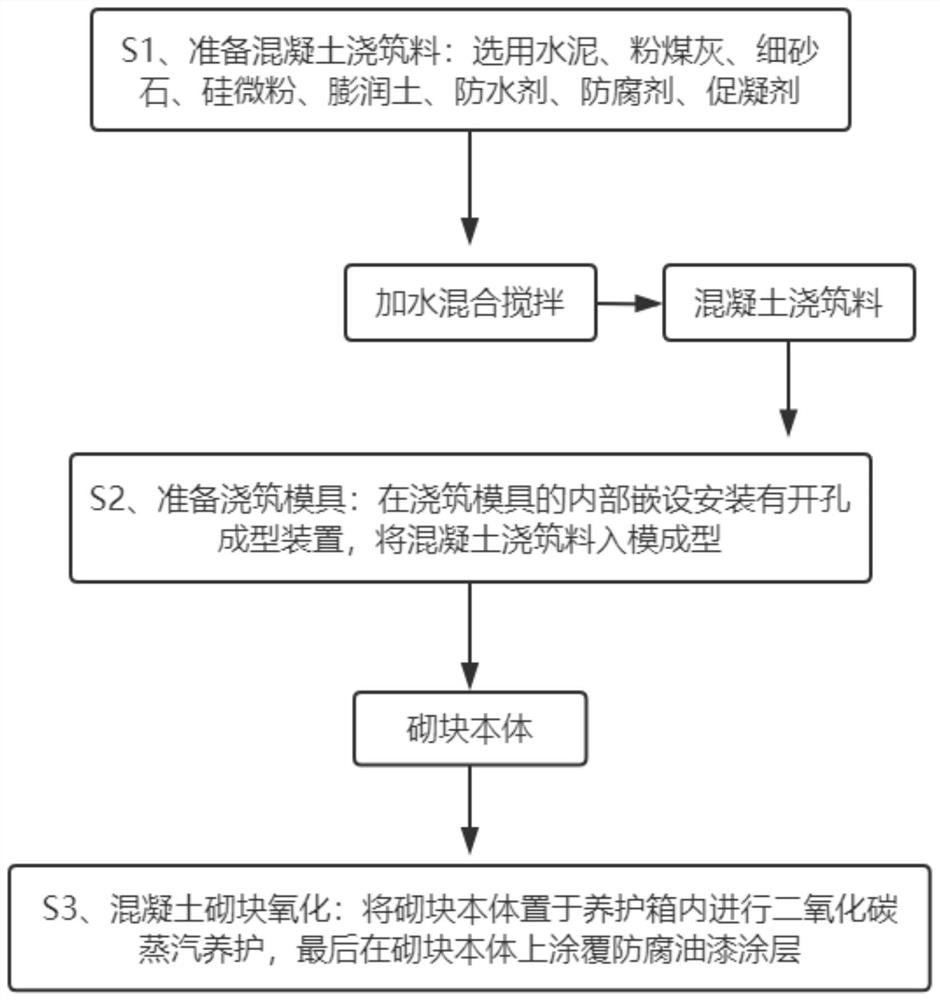

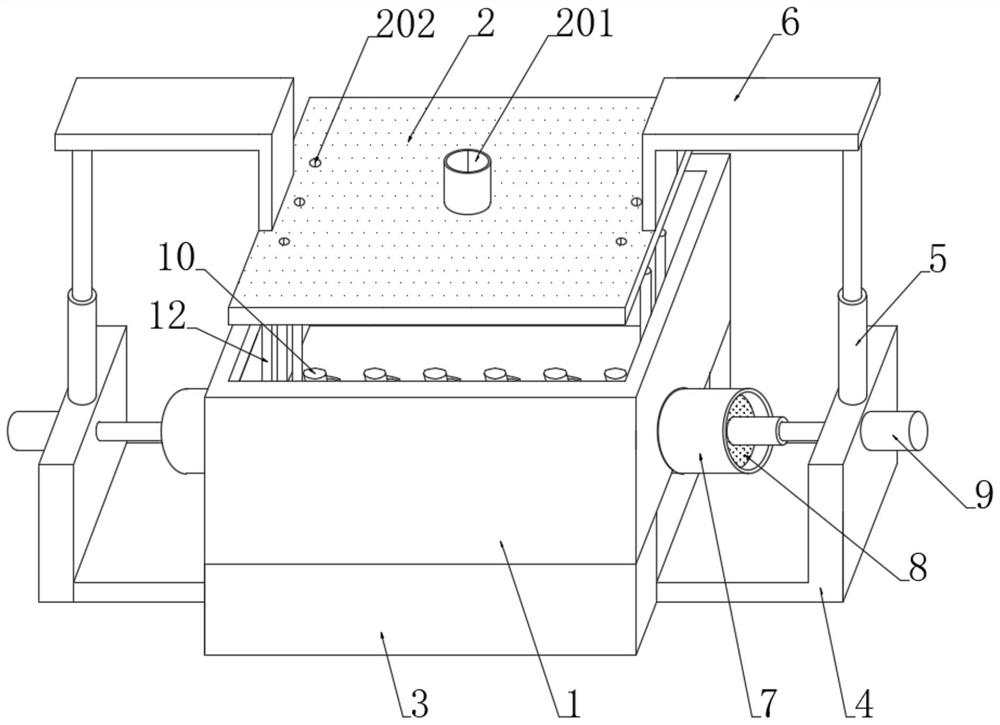

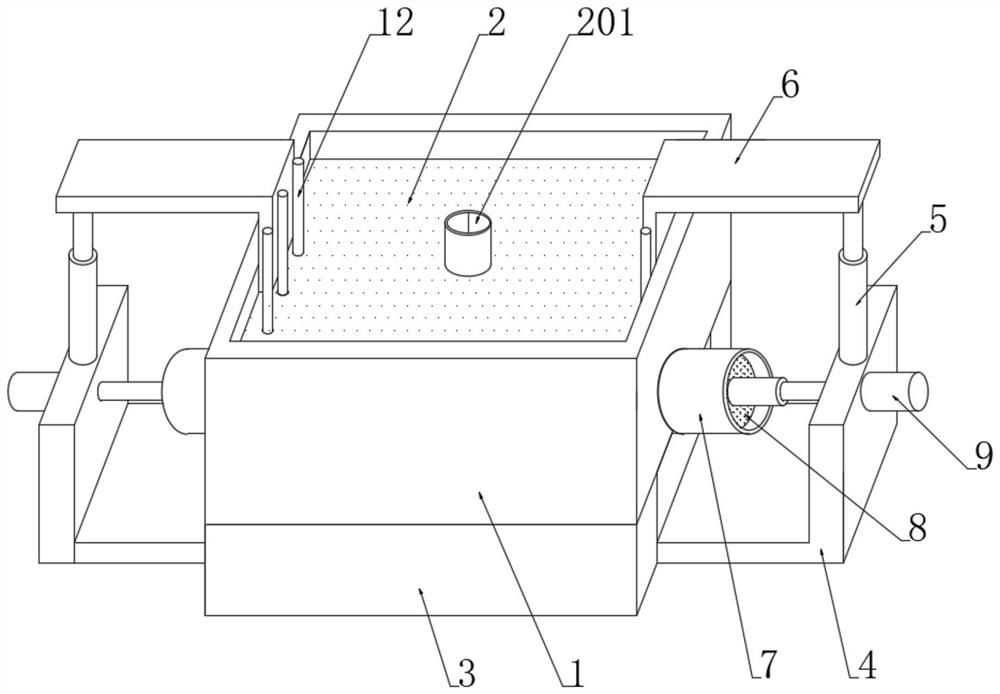

[0044] see Figure 1-2 and Figure 7 , a preparation process of self-draining concrete blocks, comprising the following preparation process steps:

[0045] S1. Prepare concrete pouring material: select cement, fly ash, fine sand, silica powder, bentonite, waterproofing agent, preservative, and coagulant with a certain mass ratio as raw materials, and mix and stir each raw material with water to obtain concrete pouring material;

[0046] S2. Prepare the pouring mold: the pouring mold is cleaned and dried in advance, and an opening forming device is embedded in the pouring mold, and the concrete pouring material obtained in S1 is introduced into the pouring mold, molded into the mold, and released after cooling. The block body 11 with self-drainage function is obtained by molding;

[0047] S3. Oxidation of concrete blocks: put the block body 11 obtained in S2 into a curing box for carbon dioxide steam curing at a curing temperature of 40-60°C. The block body 11 is coated with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com