Slip glaze and preparation method of domestic ceramic with the same

A slip glaze and daily-use technology, applied in the field of slip glaze ceramic products, can solve the problems of poor apparent quality such as glaze gloss, poor thermal shock resistance, and easy scratches, etc., to achieve good wear resistance, anti- Good thermal shock performance and quality improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

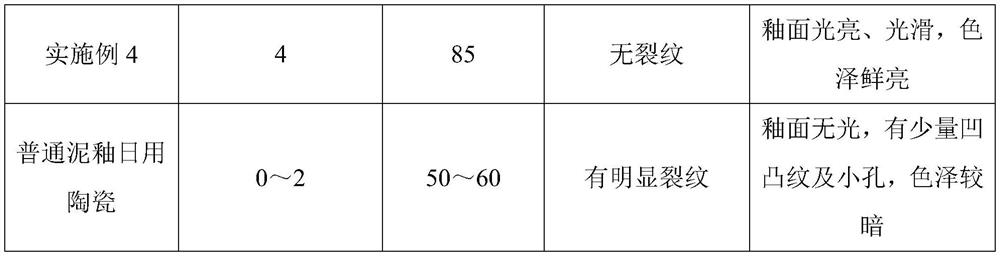

Examples

Embodiment 1

[0056] A kind of mud glaze, comprises the raw material of following weight portion:

[0057] 25-32 parts of red clay,

[0058] 6-9 parts of red loam,

[0059] Feldspar 18~22 parts,

[0060] Quartz 20-26 parts,

[0061] Niobium disilicide 2.5~3.5 parts,

[0062] 3-5 parts of nano silicon dioxide,

[0063] Nano-boron nitride 1.5-2 parts,

[0064] 5-8 parts of nano zinc oxide,

[0065] Nano magnesium oxide 1.7~2.4 parts,

[0066] Calcium Hydroxyphosphate 5-7 parts.

[0067] In this embodiment, the slip preferably but not limited to includes the following raw materials in parts by weight:

[0068] 28.5 parts of red clay,

[0069] 7.5 parts of red loam,

[0070]Feldspar 20 parts,

[0071] Quartz 23 parts,

[0072] Niobium disilicide 3 parts,

[0073] Nano silicon dioxide 4 parts,

[0074] Nano boron nitride 1.8 parts,

[0075] Nano zinc oxide 6.5 parts,

[0076] Nano magnesium oxide 2 parts,

[0077] Calcium Hydroxyphosphate 6 parts.

[0078] In this embodiment, t...

Embodiment 2

[0089] A kind of mud glaze, comprises the raw material of following weight portion:

[0090] 25 parts of red clay,

[0091] 6 parts red loam,

[0092] Feldspar 18 parts,

[0093] Quartz 20 parts,

[0094] Niobium disilicide 2.5 parts,

[0095] Nano silicon dioxide 3 parts,

[0096] Nano boron nitride 1.5 parts,

[0097] Nano zinc oxide 5 parts,

[0098] 1.7 parts of nano magnesium oxide,

[0099] Calcium Hydroxyphosphate 5 parts.

[0100] In this embodiment, the feldspar is a mixture of albite and anorthite.

[0101] In this embodiment, the mass ratio of albite and anorthite in the mixture of albite and anorthite is 1:0.26.

[0102] In this embodiment, the red clay is calcined red clay.

[0103] In this example, the particle size of the red clay is 3000 mesh.

[0104] In this embodiment, the particle size of the red loam is 4000 mesh.

[0105] Present embodiment also provides a kind of preparation method of the daily-use pottery with described mud glaze, comprises ...

Embodiment 3

[0111] A kind of mud glaze, comprises the raw material of following weight portion:

[0112] 32 parts of red clay,

[0113] 9 parts red loam,

[0114] Feldspar 22 parts,

[0115] Quartz 26 parts,

[0116] Niobium disilicide 3.5 parts,

[0117] Nano silicon dioxide 5 parts,

[0118] Nano boron nitride 2 parts,

[0119] Nano zinc oxide 8 parts,

[0120] 2.4 parts of nano magnesium oxide,

[0121] Calcium Hydroxyphosphate 7 parts.

[0122] In this embodiment, the feldspar is a mixture of albite and anorthite.

[0123] In this embodiment, the mass ratio of albite and anorthite in the mixture of albite and anorthite is 1:0.34.

[0124] In this embodiment, the red clay is calcined red clay.

[0125] In this example, the particle size of the red clay is 5000 mesh.

[0126] In this embodiment, the particle size of the red loam is 2000 mesh.

[0127] Present embodiment also provides a kind of preparation method of the daily-use pottery with described mud glaze, comprises th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com