Forming method of split tool composite material support

A molding method and tooling technology, which is applied in the field of molding of split tooling composite brackets, to achieve the effect of accurate direction, uniform and controlled pressure transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

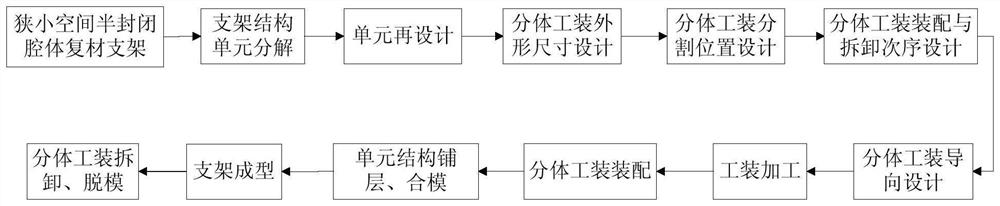

[0038]Such asfigure 1 As shown, the carrier of the present invention is a narrow space semi-closed cavity composite bracket, and its molding process is as followsfigure 2 Shown.

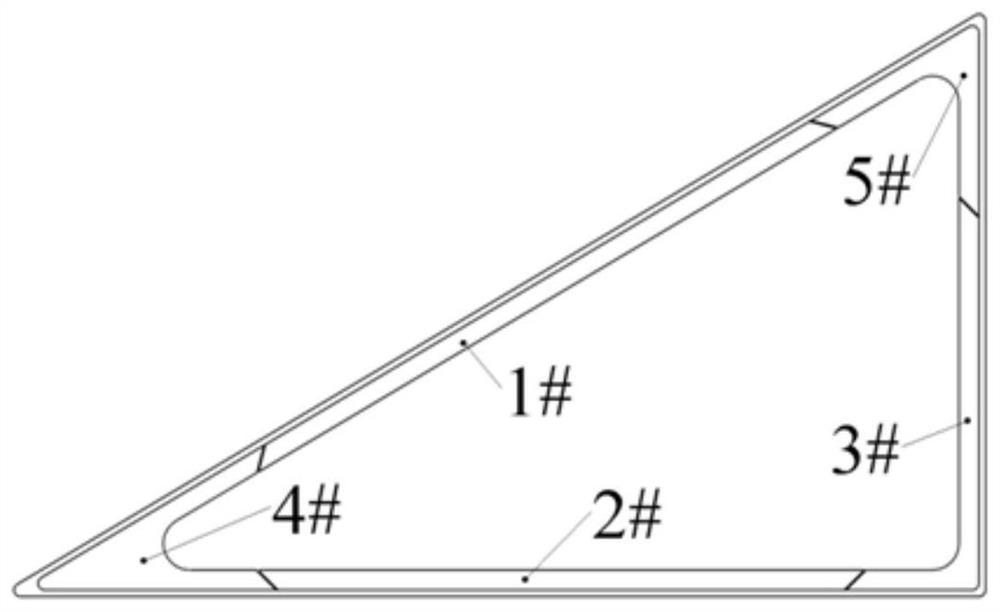

[0039]Step 1: Redesign the structure size of the element blank according to the size of the support structure (element division). Two triangular elements and one rectangular element can be divided. The decomposition line is in the middle of the vertical beam of the I-beam section. The element section after decomposition is Type C;

[0040]Step 2: Design the soft film according to the triangular unit and the rectangular unit. The cross-section of the soft film is C-shaped, and the shape is consistent with the shape of the inner cavity of the unit, and the thickness is generally 5mm. The function of the soft membrane is to evenly transmit pressure and at the same time serve as the benchmark for composite material paving;

[0041]Step 3: Design triangular and rectangular split tooling (such asimage 3 withFigure 4 (Sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com