Efficient accessory grinding machining equipment in field of machining

A technology of mechanical processing and processing equipment, which is applied in the direction of metal processing equipment, grinding/polishing equipment, grinding workpiece support, etc., which can solve the problems of inability to improve grinding efficiency, inability to adjust and fix, inability to grind accessories of different sizes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

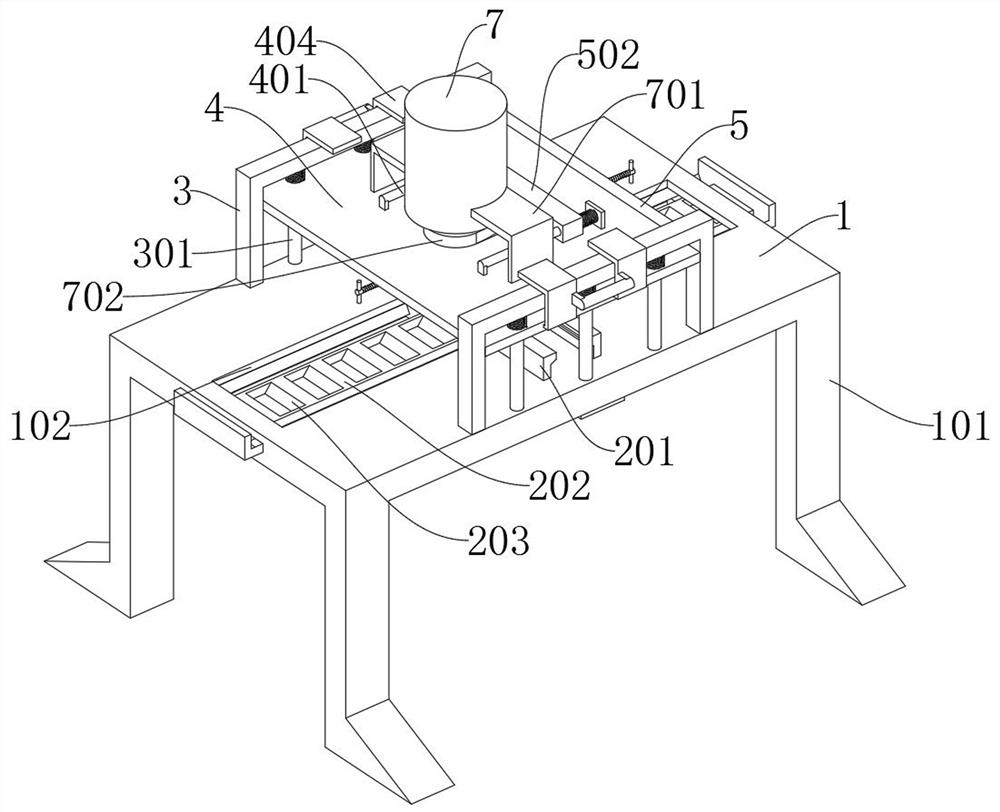

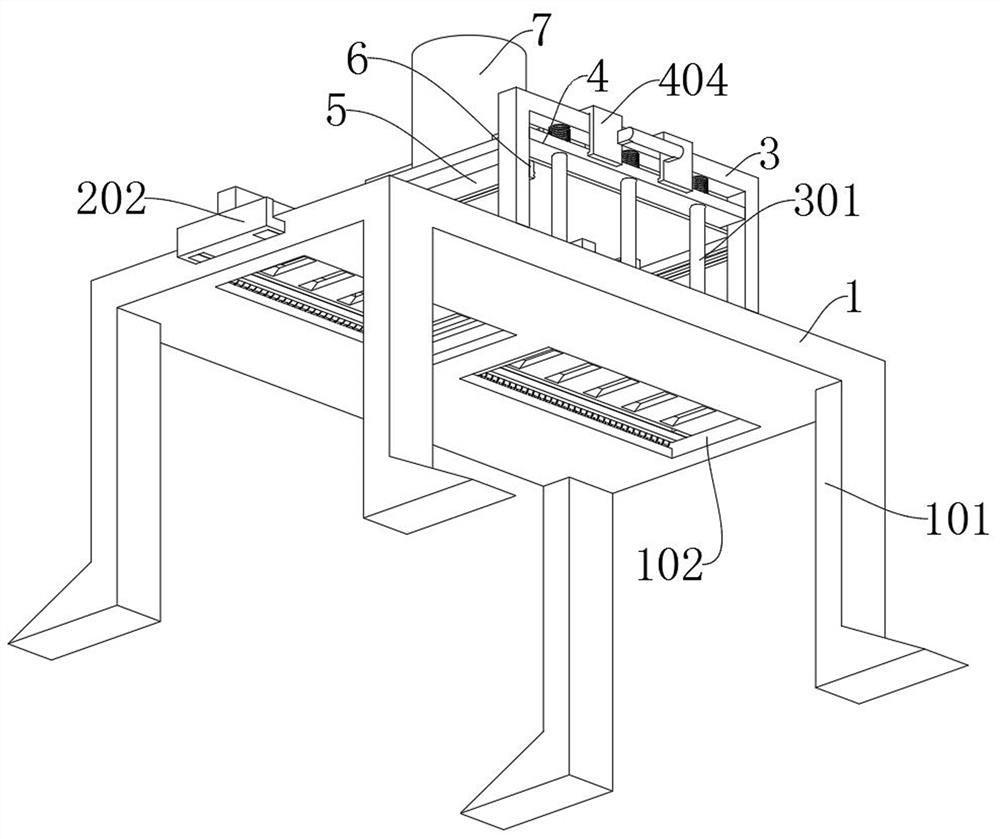

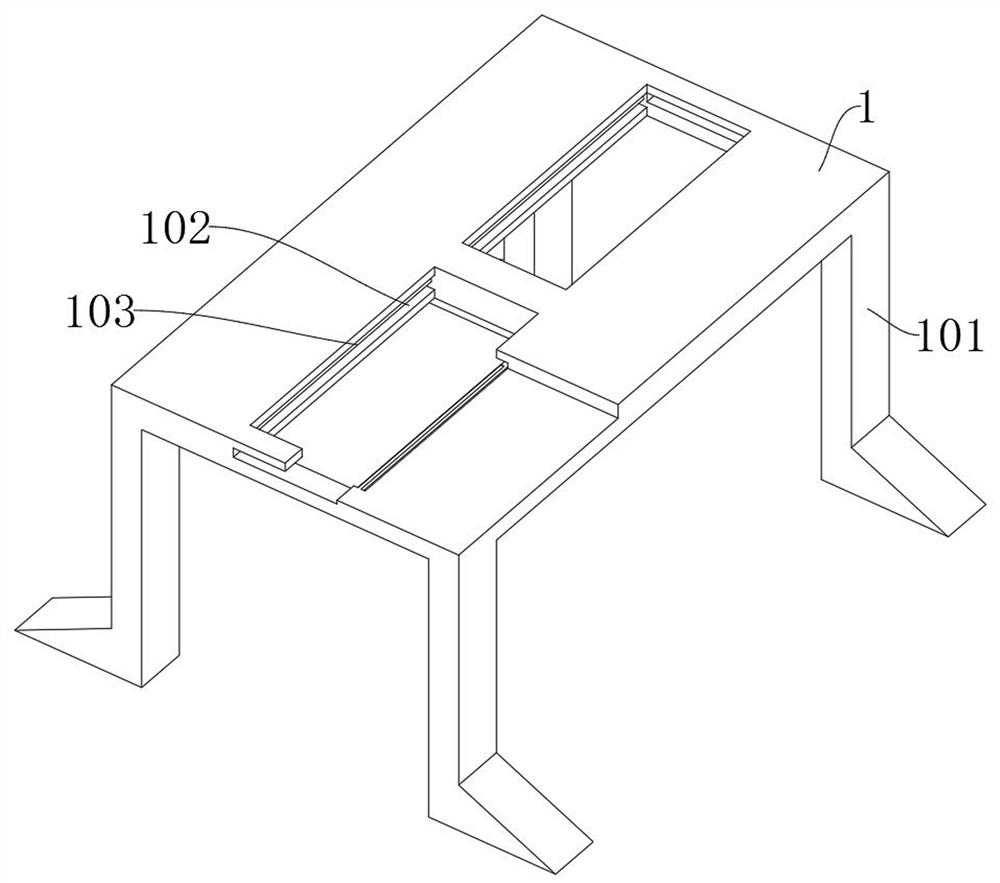

[0035] as attached figure 1 to attach Figure 9 Shown:

[0036] The present invention provides an efficient accessory grinding processing equipment in the field of mechanical processing, including a main body 1, a top part 2, a side part 3, a moving plate 4, a mounting part 5, a splint 6 and a motor 7; the main body 1 is a rectangular plate structure, And the bottom of the main body 1 is provided with a support member 101; the side member 3 is arranged at the middle position on both sides of the top of the main body 1, and the side bar 301 inside the side member 3 is connected with the top of the main body 1; The bottom, and the guide head 501 at the top of the mounting part 5 is embedded in the inner groove 402, and the support rod 401 is inserted into the round hole of the force head 502 at the top of the mounting part 5; the splint 6 is installed on both sides of the bottom of the mounting part 5 , and the adjustment rod 601 on the outside of the splint 6 is threaded insi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com