V-shaped groove weld joint forming tool and preparation method of gasket of V-shaped groove weld joint forming tool

A technology for forming tooling and groove welds, which is applied in the field of weld formation, can solve problems such as the difficulty in fixing the liner and the error-prone welding process, and achieve the effects of improving the use value, high fixing strength, and convenient adjustment and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

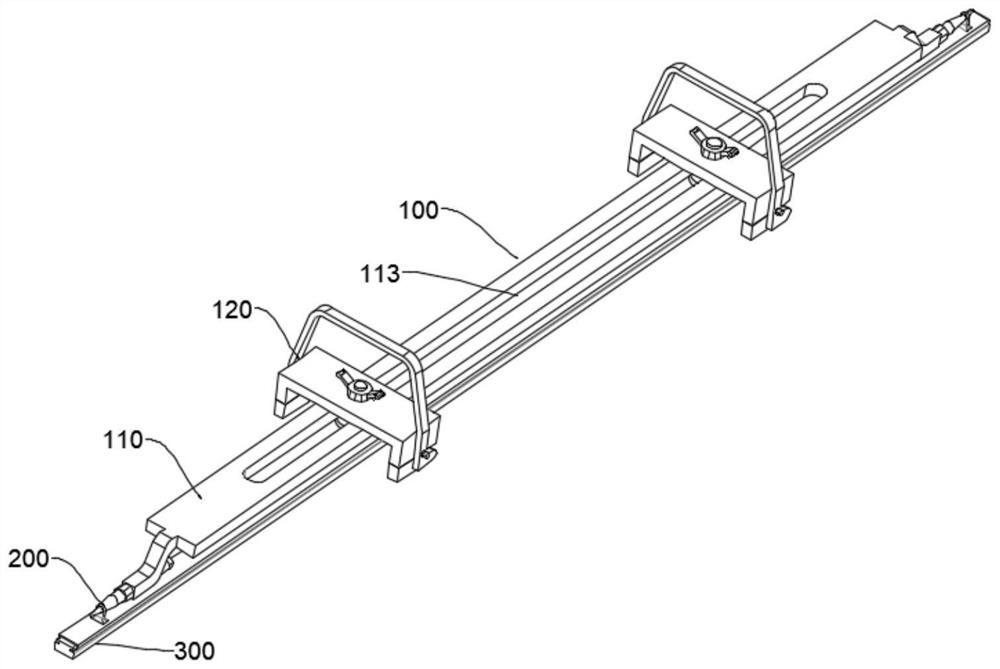

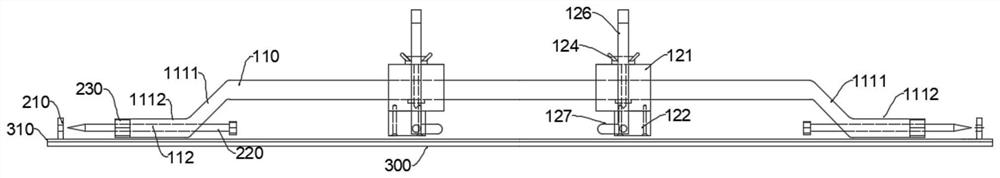

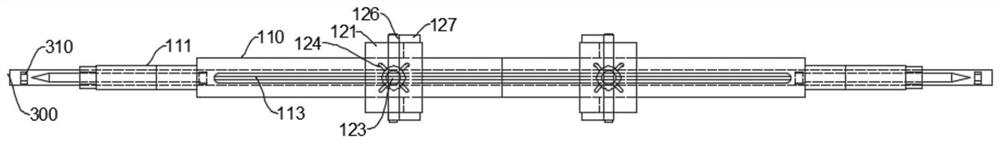

[0048] Such as Figure 1 to Figure 3 As shown, a V-groove weld forming tool is used for V-groove welding, which includes three main components: a pressing device 100, a connecting device 200 and a flexible pad 300, through which three components Complete the welding seam forming work on the V-groove. Among them, the flexible gasket 300 adopts a heat-resistant fiber structure, and in order to be able to adapt to the back of the weld seam of the V-shaped groove and fit and seal it, the shape generally adopts a rectangular structure. The flexible gasket 300 of this embodiment adopts aluminum silicate fiber rope. The specific structure and working principle of the pressing device 100 and the connecting device 200 will be described in detail below.

[0049] The pressing device 100 includes a pressing plate 110 and a pressing assembly 120 . Wherein, the shape of the pressing plate 110 can be adaptively selected according to the actual situation, and it is a rectangular structure ...

Embodiment 2

[0068] A method for preparing the flexible pad 300 in Embodiment 1, the specific process is as follows:

[0069] 1. Use stamping equipment such as a punching machine to stamp the metal sheet, and form a row of sharp corner structures on the edges of both sides of the metal sheet, forming a shape such as Figure 8 structure shown.

[0070] 2. Then bend both sides of the metal sheet, and bend it into a Figure 9 structure as shown, and sharpen the corners with an angle grinder.

[0071] Three, such as Figure 10As shown, the bent metal sheet is placed on the rectangular flexible pad 300, and the bending parts on both sides are pressed down, so that the sharp corners are inserted into the flexible pad 300 from both sides of the flexible pad 300 to form a metal strip 310, the final formed flexible liner 300 as Figure 11 shown.

[0072] 4. Finally, spot-weld the fixing rings at the two ends of the metal strip to form a complete flexible gasket 300 assembly that can be quickly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com