Distillation still with liquid level meter

A still and liquid level gauge technology, which is applied in the field of distillation, can solve the problems of difficult cleaning and easy adhesion of solid particles in the still, so as to achieve good effect, prolong the condensation time, and avoid the effect of small residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

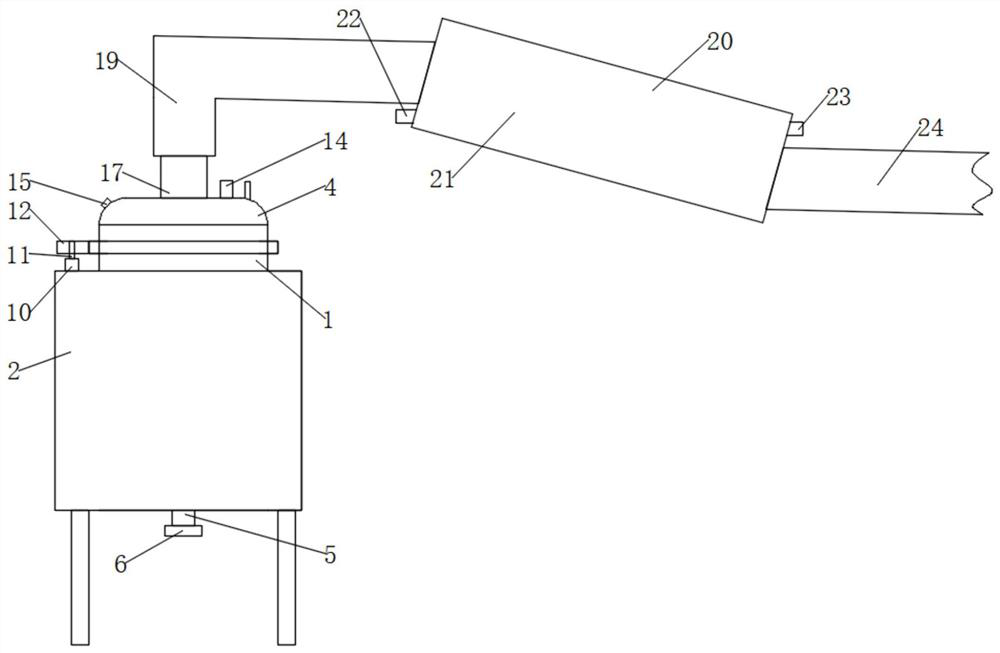

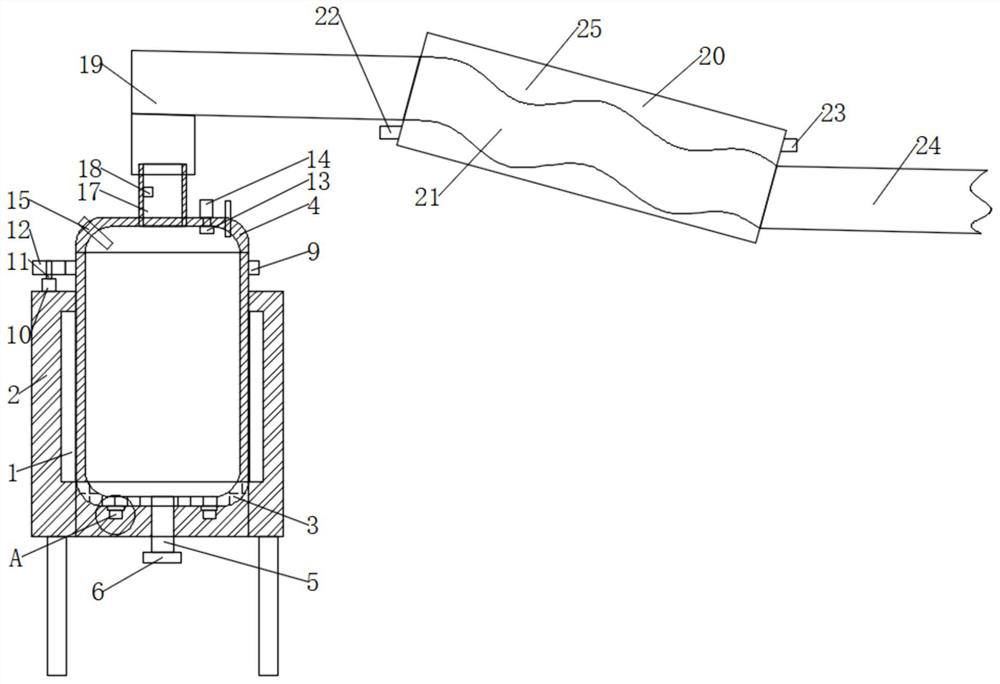

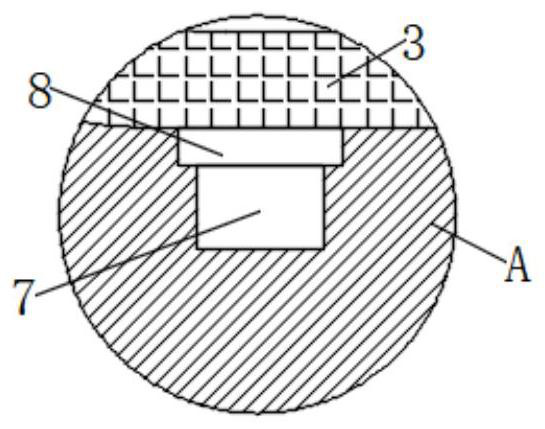

[0029] Such as Figure 1-5 As shown, the embodiment of the present invention provides a still with a liquid level gauge, which includes a still body 1 and a place for distillation. The outer surface of the still body 1 is provided with a support frame 2 to support the still body. The outer surface and above the supporting frame 2 are fixedly connected with a gear ring 9 to transmit power to make the kettle body 1 rotate. Pipe 5 discharges high-boiling point materials and solid particles. The end of the discharge pipe 5 away from the bottom 3 is fixedly connected with a valve 6 to control the discharge of the discharge pipe 5. The lower surface of the bottom 3 of the kettle is fixedly connected with a heat shield 8 to separate The heat of the bottom 3 of the kettle, the lower surface of the heat shield 8 is provided with a vibrating motor 7, which vibrates the body of the kettle 1 to prevent the solid from contacting the bottom of the kettle 3 for a long time, thereby bonding, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com