Safety type liquid level height and liquid level potential comprehensive testing device

A technology for liquid level and comprehensive testing. It is used in measuring devices, packaging, large containers, etc. It can solve the problems of abnormal liquid level potential monitoring and early warning of difficult liquid materials, the floating ball is easy to contact the pipe wall, and it is not suitable for online monitoring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

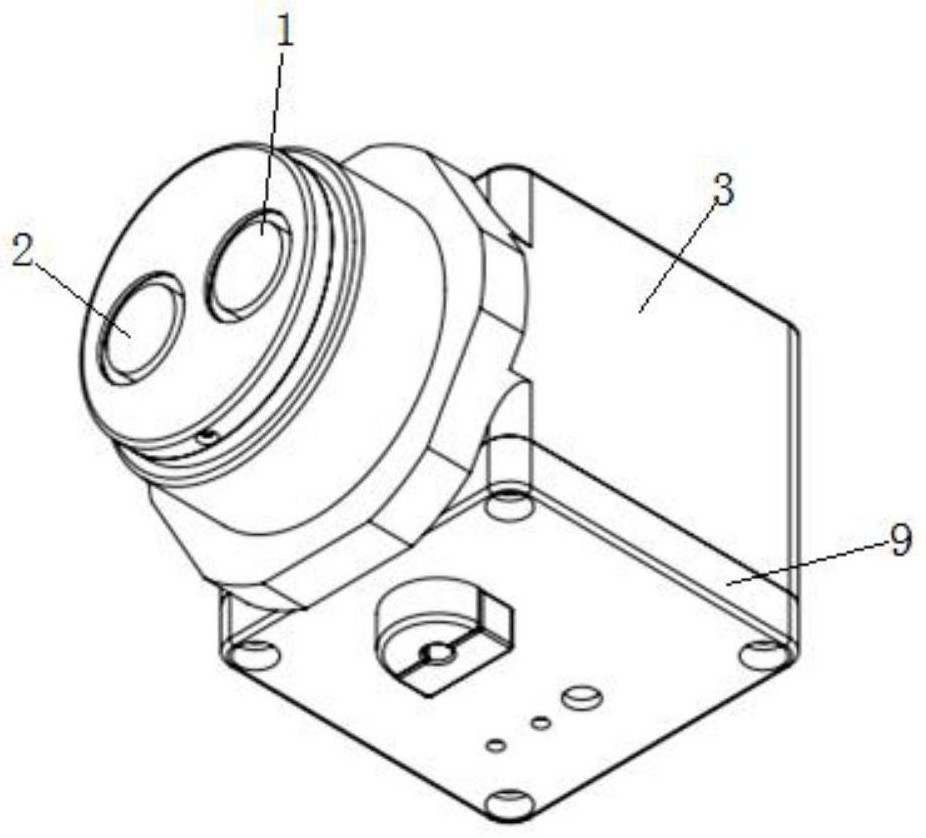

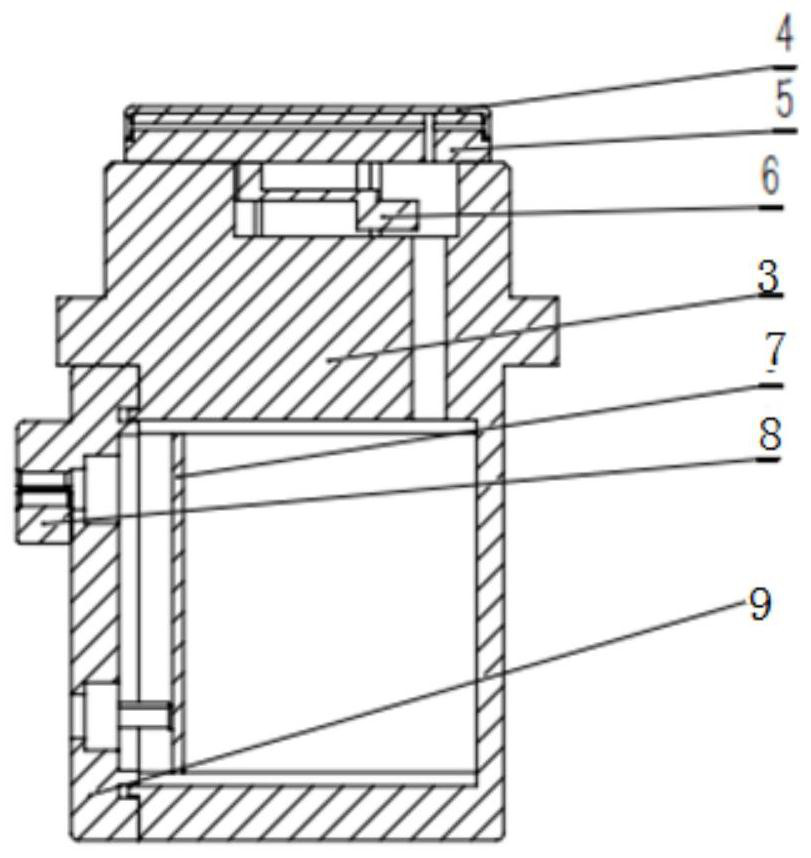

[0027] A safe comprehensive testing device for liquid level height and liquid level potential, including a casing, is used for real-time monitoring of liquid level height and liquid level potential of liquid materials in storage tanks.

[0028] The casing is provided with an upper cover 9, a static sensitive probe unit 1 and a liquid level sensing probe unit 2. The static sensitive probe unit 1 can be a non-contact micro-electromechanical system (MEMS) static sensitive probe unit, and the casing 3 is provided with a signal processing unit. The signal processing and control unit 7 is electronically connected with the control unit 7 , the electrostatic sensitive probe unit 1 and the liquid level sensing probe unit 2 .

[0029] A cylindrical head protrudes from one end surface of the shell 3, the signal processing and control unit is located in the square body, and the electrostatic sensitive probe unit and the liquid level sensing probe unit are located in the head.

[0030] The...

Embodiment 2

[0039] A safe comprehensive testing device for liquid level height and liquid level potential, including a casing, is used for real-time monitoring of liquid level height and liquid level potential of liquid materials in storage tanks.

[0040] The casing is provided with an upper cover 9, a static sensitive probe unit 1 and a liquid level sensing probe unit 2. The static sensitive probe unit 1 can be a non-contact micro-electromechanical system (MEMS) static sensitive probe unit, and the casing 3 is provided with a signal processing unit. The signal processing and control unit 7 is electronically connected with the control unit 7 , the electrostatic sensitive probe unit 1 and the liquid level sensing probe unit 2 .

[0041] The shell 3 includes a square body, a cylindrical head protrudes from one end surface of the square body, the signal processing and control unit is located in the square body, and the electrostatic sensitive probe unit and the liquid level sensing probe unit ...

Embodiment 3

[0051] A safe comprehensive testing device for liquid level height and liquid level potential, including a casing, is used for real-time monitoring of liquid level height and liquid level potential of liquid materials in storage tanks.

[0052] The casing is provided with an upper cover 9, a static sensitive probe unit 1 and a liquid level sensing probe unit 2. The static sensitive probe unit 1 can be a non-contact micro-electromechanical system (MEMS) static sensitive probe unit, and the casing 3 is provided with a signal processing unit. The signal processing and control unit 7 is electronically connected with the control unit 7 , the electrostatic sensitive probe unit 1 and the liquid level sensing probe unit 2 .

[0053] The shell 3 includes a square body, a cylindrical head protrudes from one end surface of the square body, the signal processing and control unit is located in the square body, and the electrostatic sensitive probe unit and the liquid level sensing probe uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com