Liquid storage tank anti-condensing structure, liquid storage tank and compressor

A liquid storage tank and anti-condensation technology, applied in the field of compressors, can solve problems such as falling into and unable to wrap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

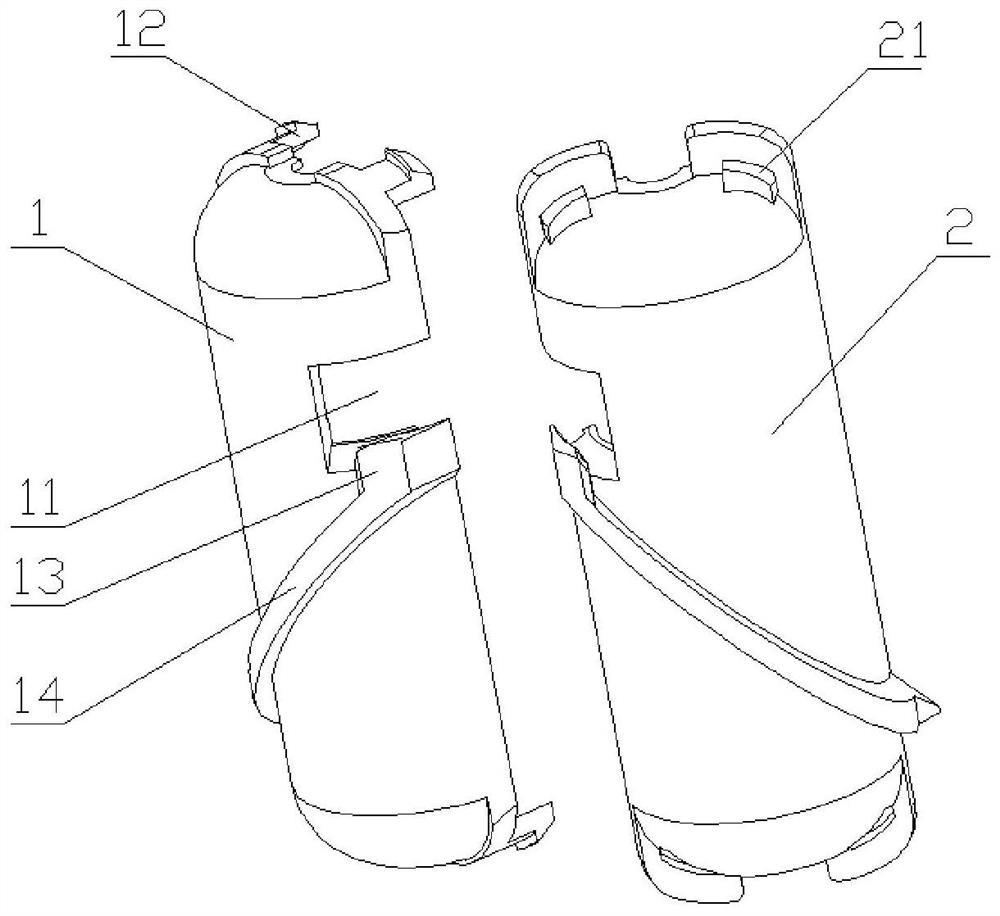

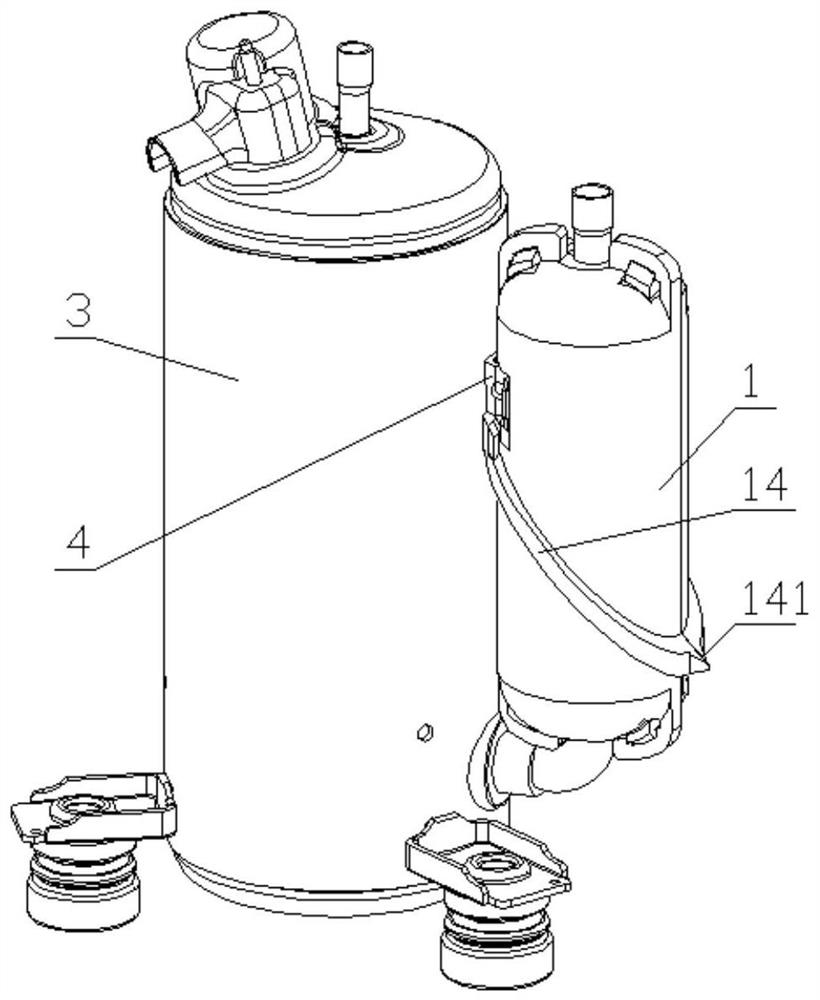

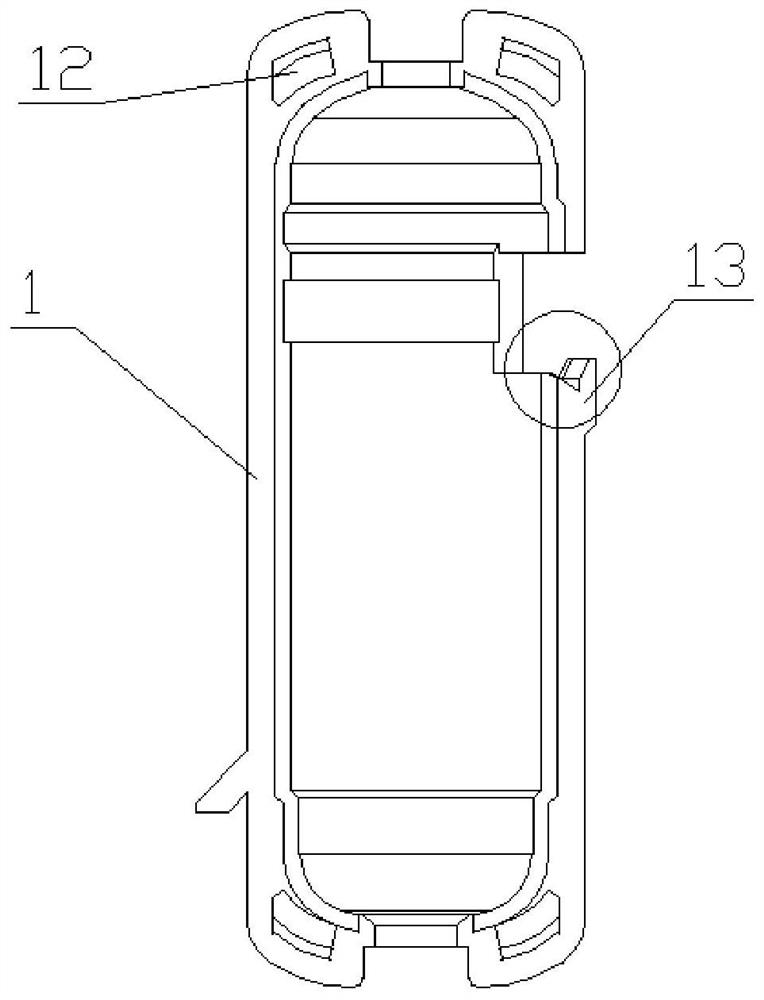

[0025] see in conjunction Figure 1 to Figure 6 As shown, according to an embodiment of the present application, an anti-condensation structure of a liquid storage tank includes:

[0026] The casing wraps the liquid storage tank; the casing is provided with a mounting hole 11 for penetrating one end of the installation boss 4 and fixing it with the liquid storage tank;

[0027] The housing is provided with a liquid storage tank 13 capable of receiving condensation on the installation boss 4 .

[0028] A shell is covered outside the liquid storage tank, and a liquid storage tank 13 is arranged on the shell to receive the condensation from the installation boss 4, so as to avoid safety problems caused by the condensation falling into the ground wire of the compressor 3, or Issue with complaints about falling to the ground.

[0029] In some embodiments, a flow guide mechanism is provided on the casing, one end of which communicates with the liquid storage tank 13 and can lead o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com