Oil level potential monitoring and interlocking control system

A technology of potential monitoring and interlocking control, applied in special dispensing devices, containers, packaging, etc., which can solve problems such as real-time monitoring of difficult oil levels, unsuitable for online monitoring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

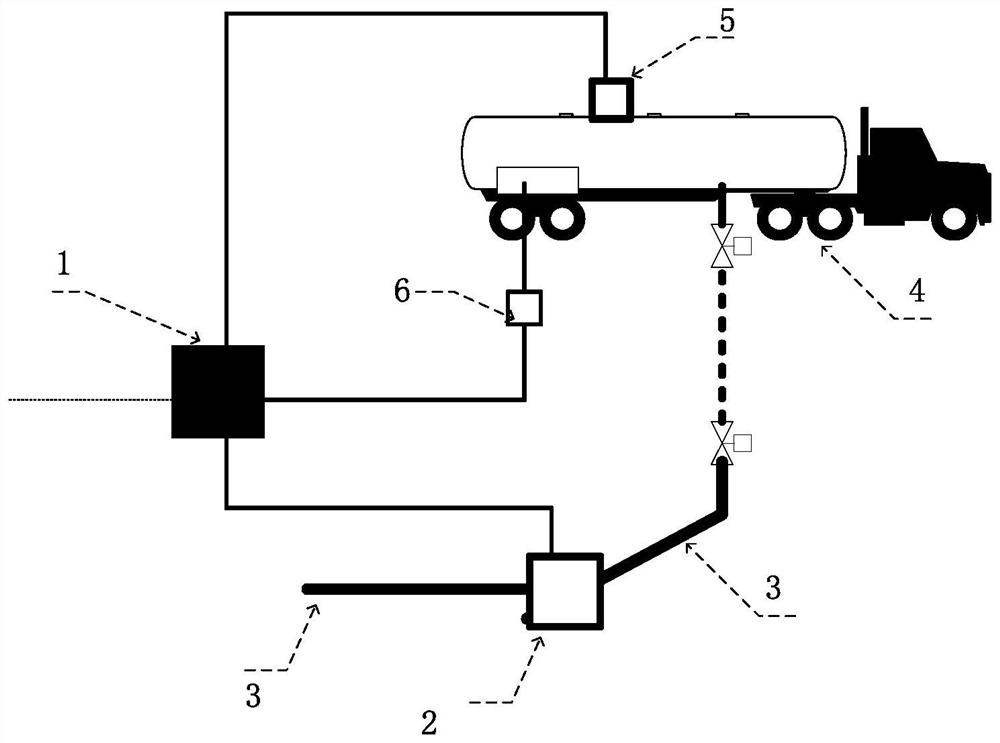

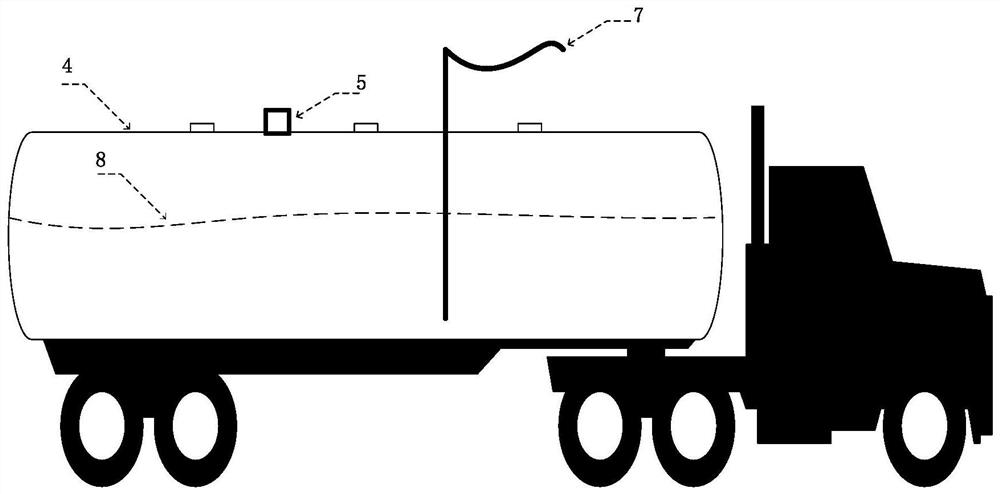

[0029] An oil level potential monitoring and interlocking control system, which is mainly used in the process of loading and unloading oil products, including oil delivery control unit 1, oil level potential test unit 5, oil delivery control valve 2, oil level potential test unit, Both the electrostatic grounding detection unit and the oil delivery control valve are electronically connected to the oil delivery control unit, the oil delivery control valve is installed on the oil delivery pipeline 3, and the oil level potential test unit 5 is installed at the center of the top of the storage tank 4.

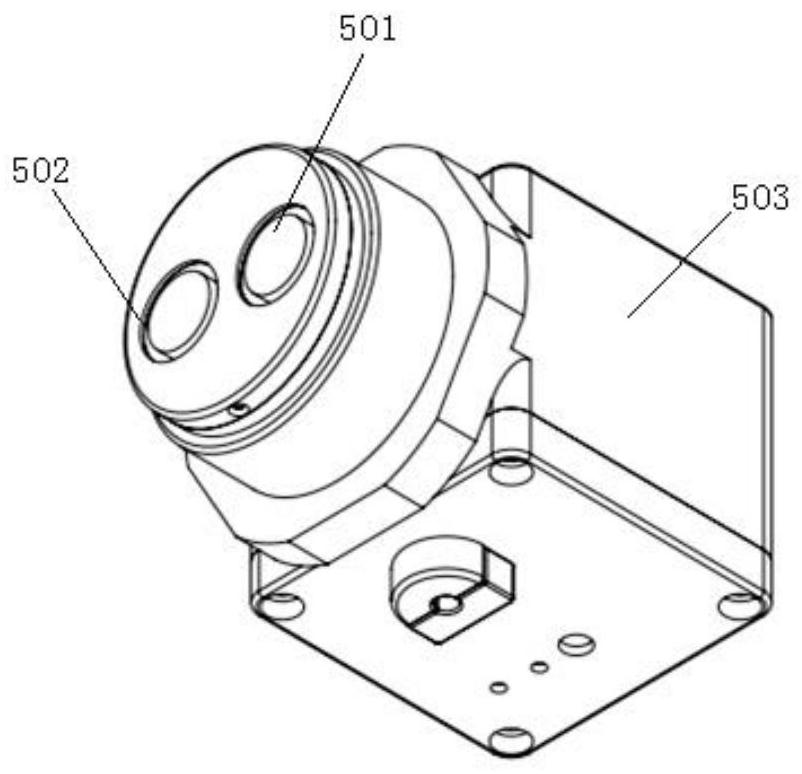

[0030] The oil level potential test unit 5 includes an electric field sensing module 501, an ultrasonic distance measuring module 502 and a data processing module. After the electric field sensing module 501 and the ultrasonic distance measuring module 502 are sealed by glue sealing, the corresponding probes point to the storage tank from the top of the storage tank The internal liq...

Embodiment 2

[0038] An oil level potential monitoring and interlocking control system, which is mainly used in the process of loading and unloading oil products, including oil delivery control unit 1, oil level potential test unit 5, oil delivery control valve 2, oil level potential test unit, Both the electrostatic grounding detection unit and the oil delivery control valve are electronically connected to the oil delivery control unit, the oil delivery control valve is installed on the oil delivery pipeline 3, and the oil level potential test unit 5 is installed at the center of the top of the storage tank 4.

[0039] The oil level potential test unit 5 includes an electric field sensing module 501, an ultrasonic distance measuring module 502 and a data processing module. After the electric field sensing module 501 and the ultrasonic distance measuring module 502 are sealed by glue sealing, the corresponding probes point to the storage tank from the top of the storage tank The internal liq...

Embodiment 3

[0049] An oil level potential monitoring and interlocking control system, which is mainly used in the process of loading and unloading oil products, including oil delivery control unit 1, oil level potential test unit 5, oil delivery control valve 2, oil level potential test unit, Both the electrostatic grounding detection unit and the oil delivery control valve are electronically connected to the oil delivery control unit, the oil delivery control valve is installed on the oil delivery pipeline 3, and the oil level potential test unit 5 is installed at the center of the top of the storage tank 4.

[0050] The oil level potential test unit 5 includes an electric field sensing module 501, an ultrasonic distance measuring module 502 and a data processing module. After the electric field sensing module 501 and the ultrasonic distance measuring module 502 are sealed by glue sealing, the corresponding probes point to the storage tank from the top of the storage tank The internal liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com