A mixing device for building construction

A technology for building construction and mixing device, which is applied in clay preparation devices, cement mixing devices, chemical instruments and methods, etc., can solve the problems of raw material stratification, easy agglomeration, impact on concrete quality, etc., so as to reduce production costs and avoid The effect of layering of raw materials and increasing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

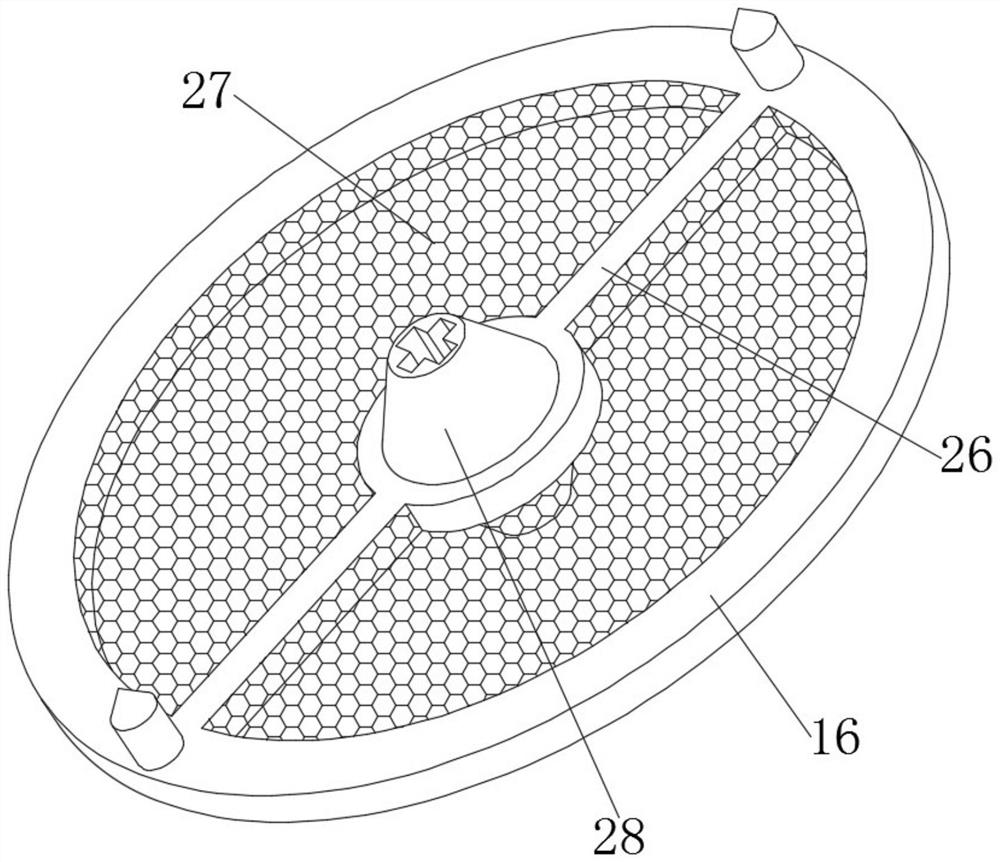

[0017] see Figure 1-4 , the present invention provides a technical solution: a mixing device for building construction, including a connecting seat 1, the connecting seat 1 is an L-shaped structure, the upper right side of the connecting seat 1 is fixedly connected with a connecting plate 2, the connecting plate 2 Rotating drum 3 is connected to the left side, the left side of drum 3 is provided with connecting shell 5, the top of connecting plate 2 is provided with feed inlet, the left side of connecting shell 5 is provided with discharge port, and discharge port is provided with For the valve, the left side of the drum 3 and the right side of the connecting shell 5 are fixedly connected with a connecting platform 6, and the two connecting platforms 6 are connected by bolts. After removing the connecting shell 5, it is convenient to take off the first sleeve 17 and The second sleeve 18 replaces the damaged part. A base 10 is provided below the connecting seat 1. The base 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com