Oblique throwing blasting mining method for gently-inclined thin ore body

A thin ore body, gently inclined technology, used in blasting, surface mining, underground mining and other directions, can solve the problems of ore quality decline, low ore grade, high mining cost, low loss rate, low filling amount, mining cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

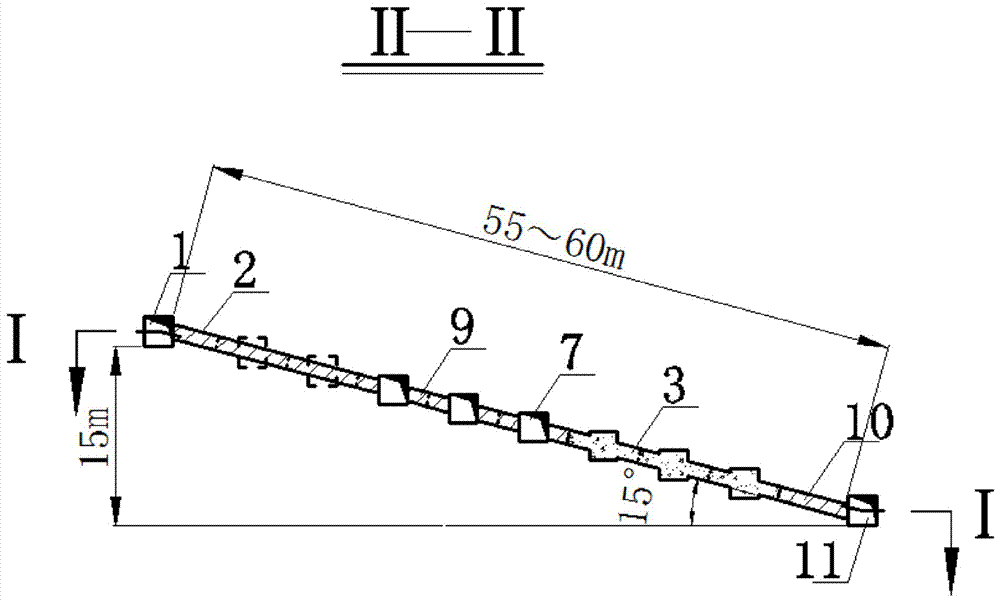

[0027] The present invention is directed at the embodiment of oblique throwing blasting mining method of gently inclined thin ore body, and it comprises the following steps: as figure 1 and figure 2 : Arrange the stope according to the stope structural parameters of the gently inclined thin ore body. After the quasi-construction is completed, the cutting lane 7 will be constructed.

[0028] A. The mining object is a gently inclined thin ore body 9 . The ore body inclination angle of the gently inclined thin ore body 9 is 5°-20°, and the thickness of the ore body is 0.4-1.0 m.

[0029] B. The stope is arranged along the strike of the ore body, and the stope structural parameters of the gently inclined thin ore body: the strike width is 40-45m, the slope length of the stope is 55-60m, the section height is 15m, the top pillar 2 is 3m long, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inclination | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com