Strip steel straightening machine and flattening method

A technology of straightening machine and strip steel, which is applied in the direction of manufacturing tools, metal rolling, metal rolling, etc., can solve the problem that the belt head cannot be threaded smoothly, and achieve the improvement of leveling operation efficiency, strong applicability, and good leveling effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

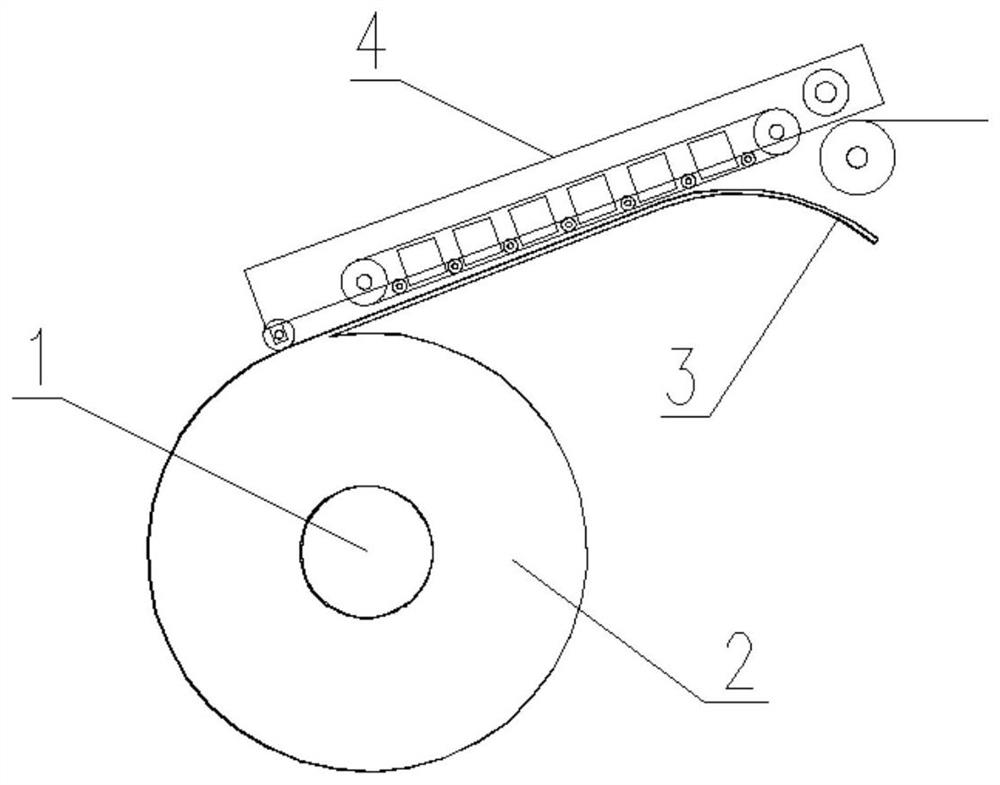

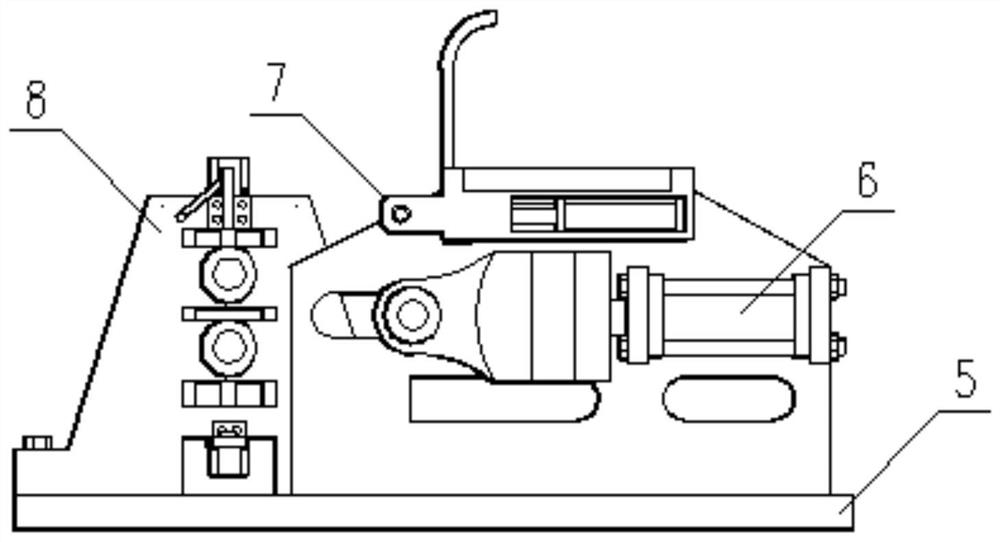

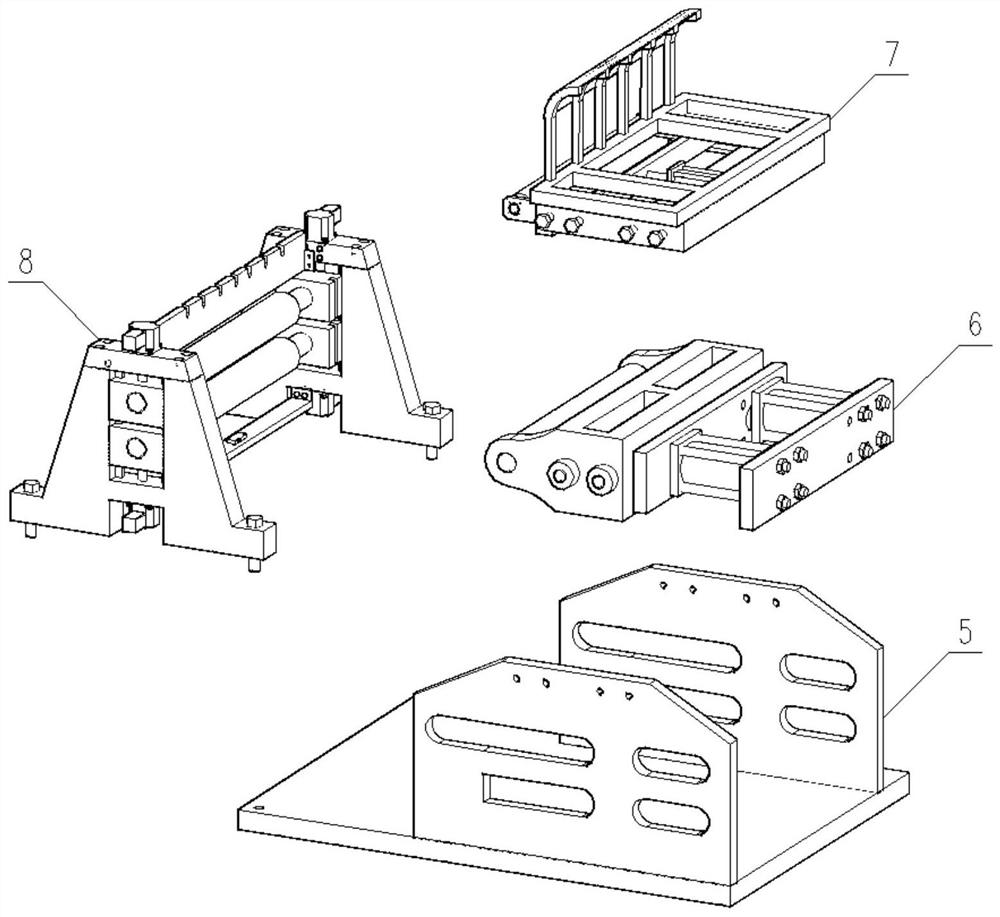

[0039] Embodiment 1: see figure 1 , refer to Figure 1-7 As shown, a strip steel straightening machine includes a base 5, an actuator 6, a magnetic mechanism 7, an adjustment mechanism 8 and the like. The adjusting mechanism 8 is installed at the front end of the base 5 , the actuator 6 is installed at the rear of the base 5 , and the magnetic mechanism 7 is located above the actuator 6 .

[0040] The base 5 is made up of a 10mm rectangular bottom plate and two side welds with a thickness, and guide grooves are arranged on the side plates at both ends thereof. Executing mechanism 6 is made up of leveling cylinder 6-1, support frame 6-2, work roll 6-3, guide wheel 6-4. Leveling cylinder 6-1 is made up of two electric cylinders, and is installed side by side in the middle position of the side plate of base 5 through base plate. The support frame 6-2 is a cavity structure, and its front end is provided with a work roll 6-3, and its rear end is connected with the push rod of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com