Bionic intestinal tract self-peristalsis reactor

A reactor and intestinal technology, applied in the field of reactors, can solve the problems of catalyst deactivation, limited mass transfer, substrate deposition, etc., and achieve the effects of simple operation, elimination of tube wall deposition, and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

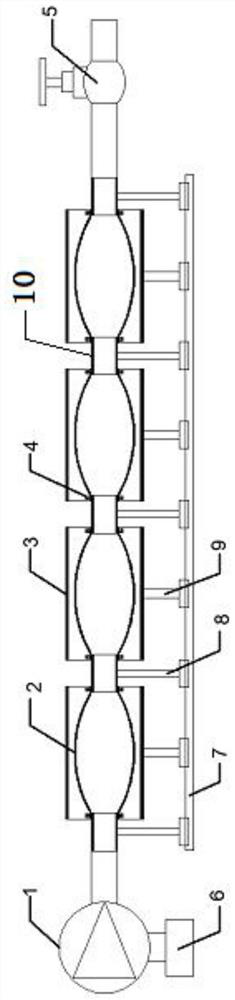

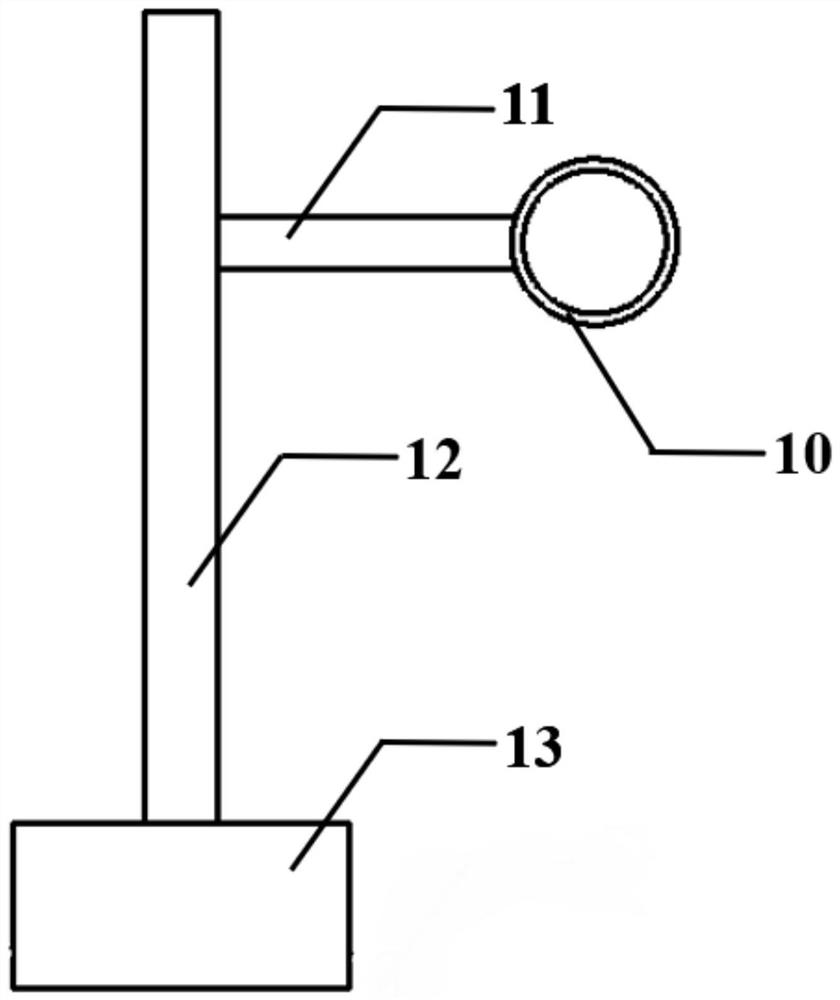

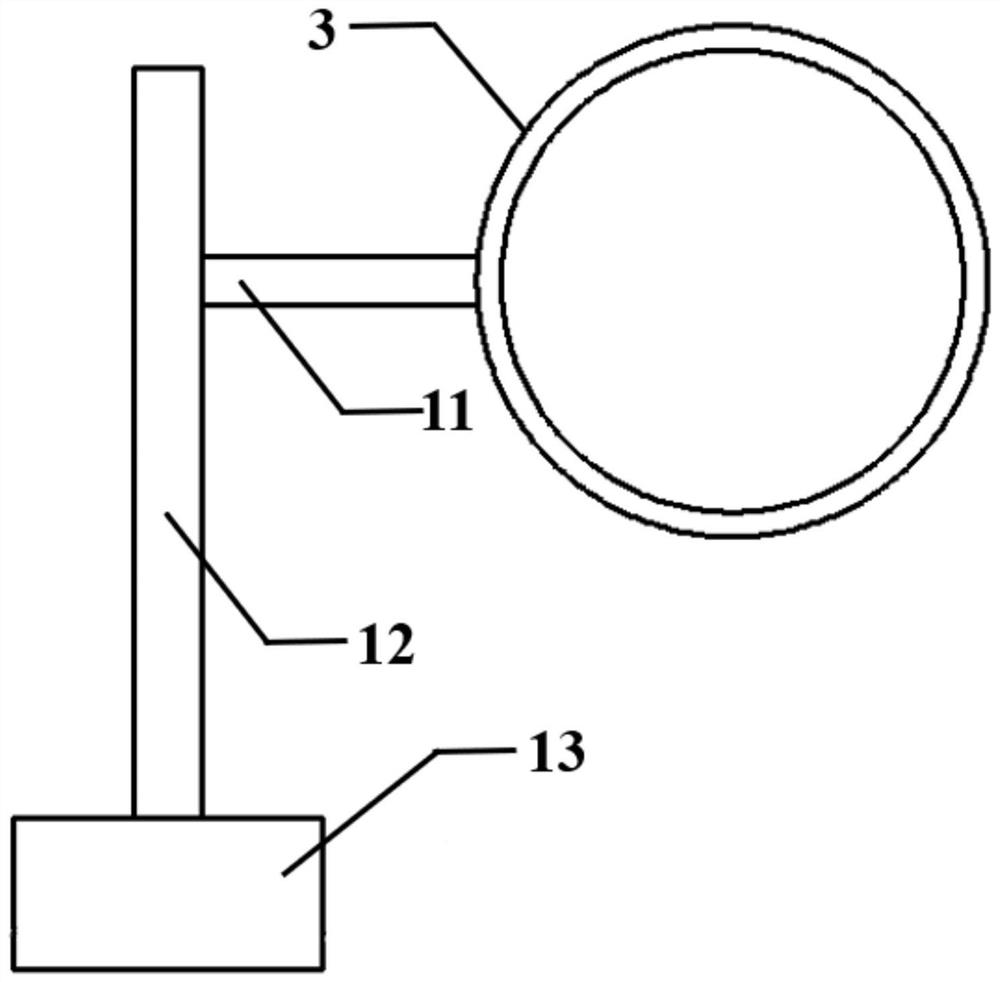

[0015] see Figure 1 to Figure 3 , a bionic intestinal self-peristaltic reactor, comprising a peristaltic driving device 1, several peristaltic sections 2, a hard sleeve 3, a fixing device and a valve 5; it is characterized in that: in the bionic intestinal self-peristaltic reactor, each The peristaltic segments are connected in series to form a bionic intestine; the front end of the bionic intestinal tract is connected to the peristaltic drive device 1, and the tail end of the bionic intestinal tract is connected to the valve 5; each peristaltic section is made of an elastic hose with a certain stretch ratio. The pulsating flow characteristics of the fluid in the elastic hose cause periodic peristalsis of the flexible elastic tube wall of the elastic hose; the outer surface of each section of the elastic hose is sleeved with a hard sleeve 3, and the hard sleeve is used to limit the elastic hose. The maximum peristaltic amplitude; the peristaltic sections of each section are r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com