Yoghourt containing clean label starch and preparation method thereof

A starchy, clean technology, used in milk preparations, dairy products, applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] The preparation of embodiment 1 clean label starch

[0065] Take a certain quality cornstarch sample and prepare it into 30% starch milk; by adding 5%Na 2 CO 3 The solution adjusts the pH value of the starch milk to 8, centrifuges and dehydrates after stirring for a certain period of time, and dries at a temperature of 45°C to obtain a dried sample; grinds the dried sample and dehydrates it at a temperature of 120°C until the moisture content is 5% , and then the temperature was raised to 180°C, and after heat treatment for 1 h according to the state of the sample, the sample was taken out to cool, crushed and sieved (with a particle size of 150 μm) to obtain clean label starch.

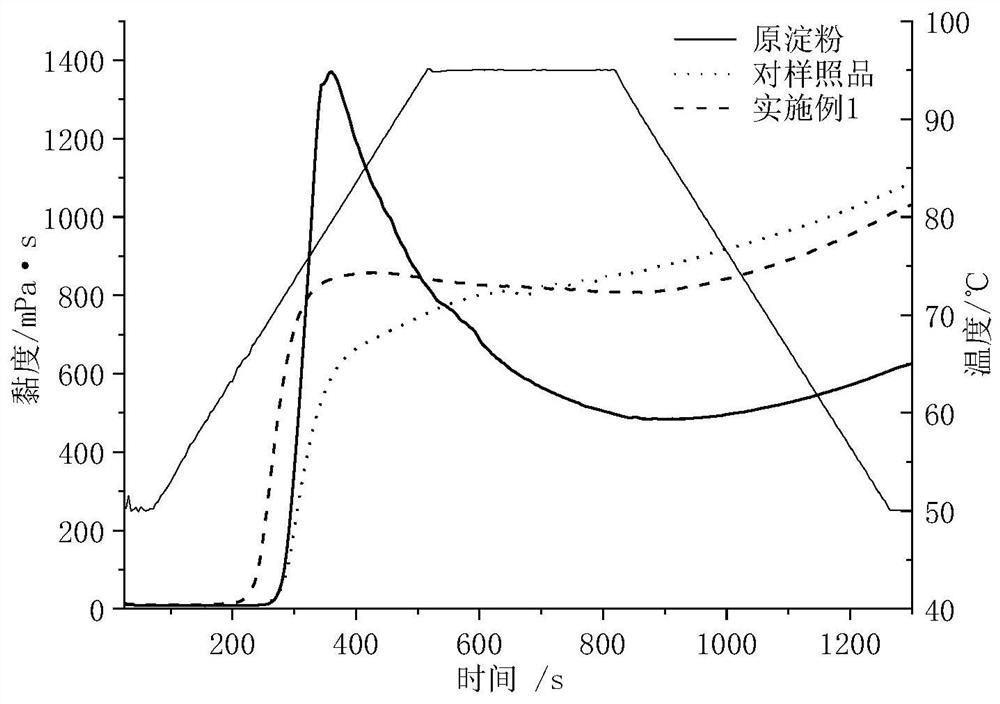

[0066] Measuring the gelatinization properties of the clean label starch prepared in Example 1, the results are shown in Table 1, figure 1 As shown, the control sample is a commercially available chemically modified starch for yogurt (COFCO Jilin Biochemical Co., Ltd., acetylated distarch ph...

Embodiment 2

[0069] The preparation of embodiment 2 clean label starch

[0070] Take a certain amount of waxy corn starch sample and prepare it into 35% starch milk; by adding 5% Na 2 CO 3 The solution adjusts the pH value of the starch milk to 9, centrifuges and dehydrates after stirring for a certain period of time, and dries at a temperature of 45°C to obtain a dried sample; grinds the dried sample and dehydrates it at a temperature of 120°C until the moisture content is less than 1%. , and then the temperature was raised to 160°C, and after heat treatment for 3 hours according to the state of the sample, the sample was taken out to cool, crushed and sieved (with a particle size of 150 μm) to obtain clean label starch.

[0071] Measure the gelatinization properties of the clean label starch prepared by Example 2, the results are as shown in Table 2, figure 2 As shown, the control sample is a commercially available chemically modified starch for yogurt (derived from acetylated distarc...

Embodiment 3

[0074] The preparation of embodiment 3 clean label starch

[0075] Take a certain amount of waxy cornstarch sample and prepare it into 40% starch milk; by adding 5% Na 2 CO 3 The solution adjusts the pH value of the starch milk to 9, centrifuges and dehydrates after stirring for a certain period of time, and dries at a temperature of 45°C to obtain a dried sample; grinds the dried sample and dehydrates it at a temperature of 120°C until the moisture content is less than 1%. , and then the temperature was raised to 170°C, and after heat treatment for 1 h according to the state of the sample, the sample was taken out to cool, crushed and sieved (with a particle size of 150 μm) to obtain clean label starch.

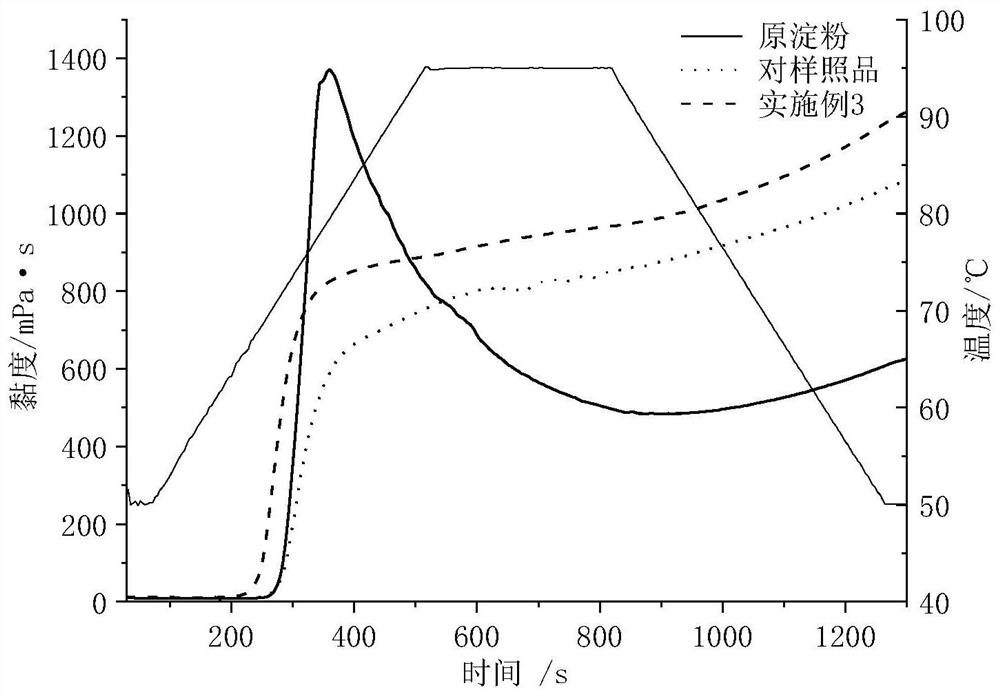

[0076] Measure the gelatinization properties of the clean label starch prepared by Example 3, the results are as shown in Table 3, image 3 As shown, the control sample is a commercially available chemically modified starch for yogurt (COFCO Jilin Biochemical Co., Ltd., ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com