Grouting sleeve grouting defect detection method based on sound wave local resonance scattering characteristics

A grouting sleeve and local resonance technology, which is applied in the direction of material analysis, measuring device, and instrument using sonic/ultrasonic/infrasonic waves, to achieve the effect of simple process, improved accuracy, and elimination of artificial errors or contact surfaces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1 judges whether it is empty through a mathematical model

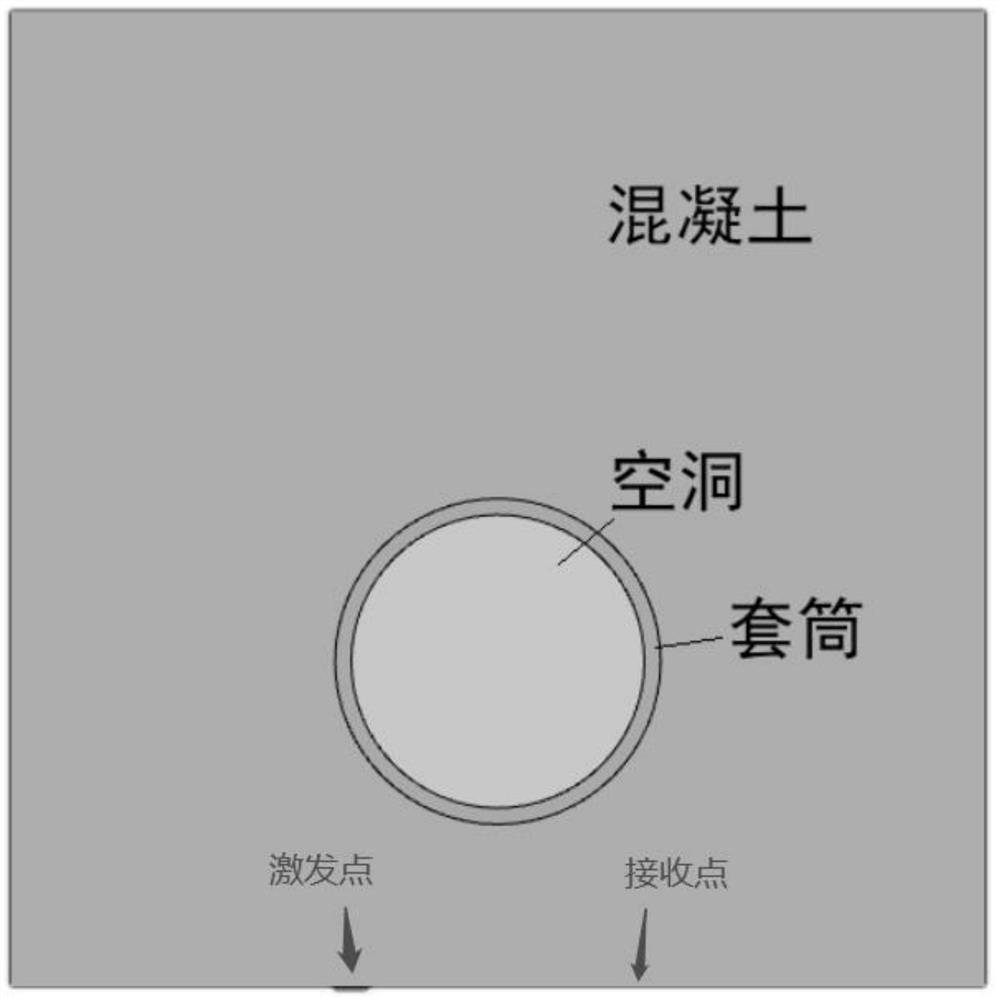

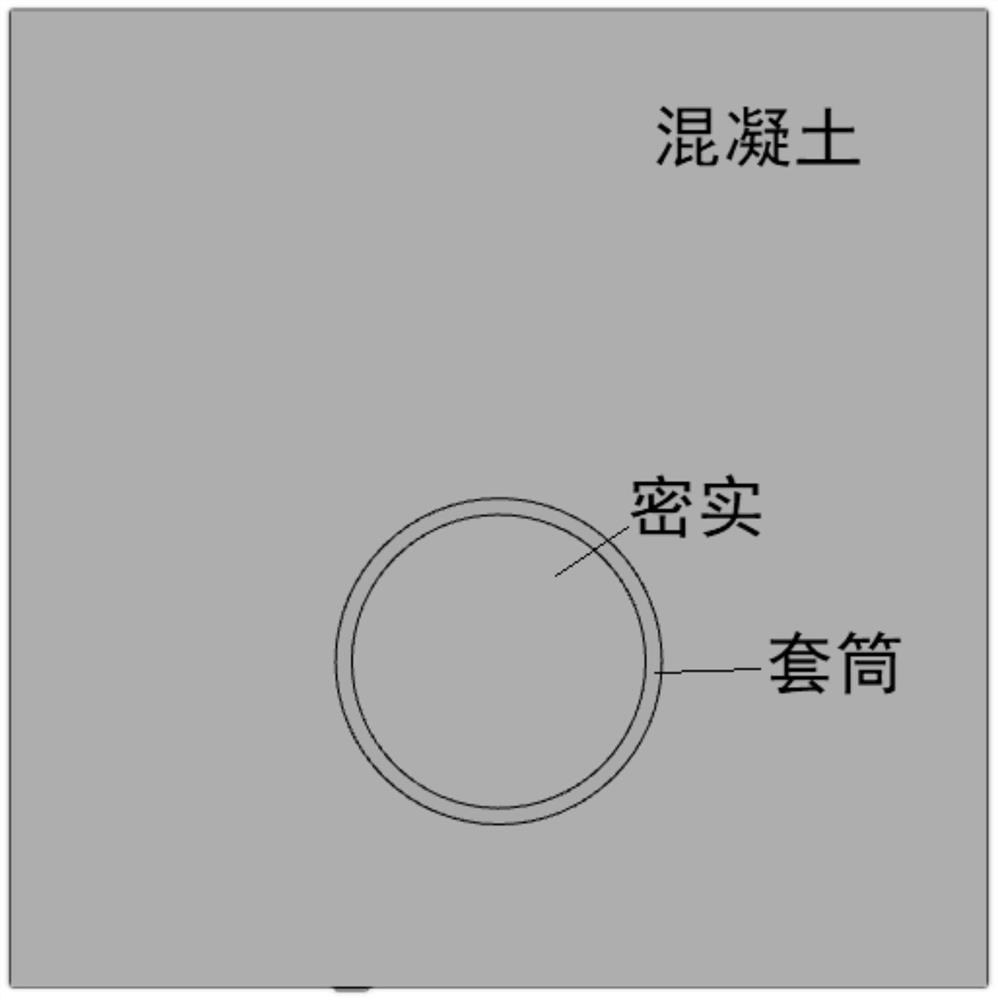

[0042] (1) Establish the finite element model of the steel sleeve grouting structure, simulate the typical steel sleeve grouting defects to select the material model, and set the elastic modulus (E), density (ρ), Poisson’s ratio (v) of the relevant materials according to the actual situation ), the finite element model of the steel sleeve grouting structure is established in COMSOLMultiphysics, and the typical steel sleeve grouting defects are simulated, such as figure 2 , image 3 As shown, the material parameters used are shown in Table 1.

[0043] Table 1

[0044] E(GPa) ρ(kg / m) v concrete 33 2600 0.2 Steel Pipe 200 7850 0.3

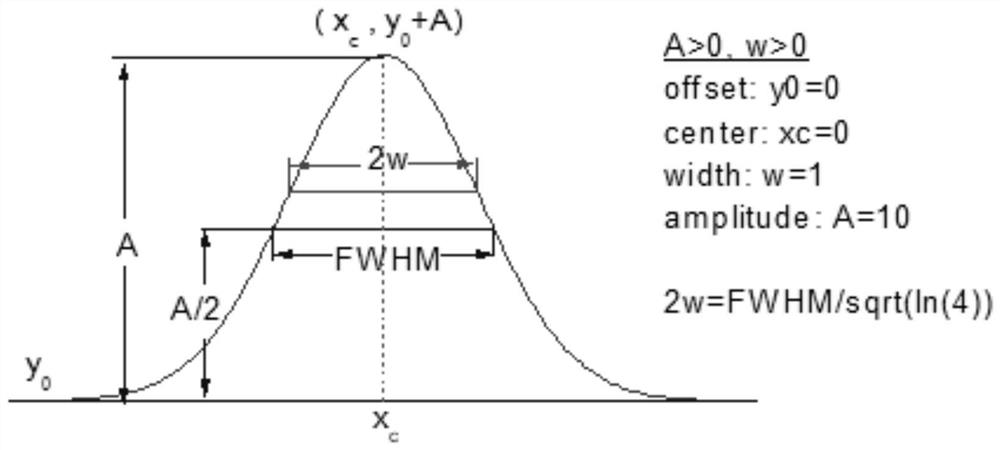

[0045](2) In COMSOL Multiphysics, before exciting the sound wave, it is necessary to set the energy A of the exciting signal, the frequency of the half-sine function, and the position of the exciting point, etc. figure 2 and image 3...

Embodiment 2

[0054] Embodiment 2 judges whether it is empty by physical experiment

[0055] In this embodiment, a TH402 bellows grouting quality non-destructive tester is used for acoustic detection and analysis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com