Method for improving Suda saline-alkali soil and generating biochemical fulvic acid raw material

A technology for biochemical fulvic acid and soda saline-alkali soil, applied in chemical instruments and methods, organic fertilizers, fertilizer mixtures, etc., to achieve the effects of eliminating soil compaction, enhancing salt resistance, and enhancing soil fertilizer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

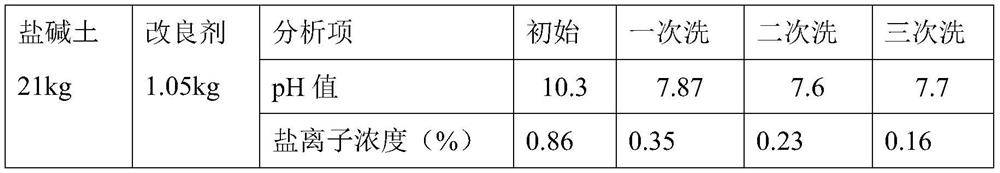

Embodiment 1

[0034] Include the following steps:

[0035] (1) Making steam puffed straw

[0036] Crush the remaining part of the material after harvesting the corn seeds, remove the soil from the material, convey it into the tank with a belt, add steam, pressurize it, and spray it into the puffing bin to obtain steam puffed straw. The puffing process pressure is 0.4Mpa, temperature is 140°C, The time is 40min, spraying instantly;

[0037] (2) Production of biochemical fulvic acid raw materials

[0038] Steam puffed straw is mixed with compound bacteria, the temperature is 50-55°C, fermented for 5 days, dried by a low-temperature drying system, the temperature is 20°C, the moisture content is <10%, stored at room temperature, crushed, and passed through a 40-mesh sieve to obtain Biochemical fulvic acid raw material, sealed and stored at low temperature;

[0039] The composite bacteria are: Bacillus megaterium: Bacillus subtilis: Bacillus flexure=1:1:1;

[0040] (3) Saline-alkaline soil mu...

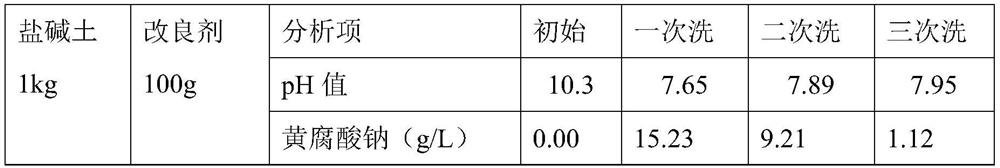

Embodiment 2

[0045] Include the following steps:

[0046] (1) Making steam puffed straw

[0047] Crush the remaining part of the corn after harvesting the seeds, remove the soil from the material, convey it into the tank with a belt, add steam, pressurize it, and spray it into the puffing bin to obtain steam puffed straw. The puffing process pressure is 1.2Mpa, temperature is 170°C, The time is 25 minutes, and it is sprayed instantly;

[0048] (2) Production of biochemical fulvic acid raw materials

[0049] Steam puffed straw is added with compound bacteria and mixed evenly, the temperature is 60-65°C, fermented for 6 days, dried by a low-temperature drying system, the temperature is 45°C, the moisture content is <10%, stored in a low-temperature seal, crushed, and passed through a 60-mesh sieve. The raw material of biochemical fulvic acid is obtained, and it is sealed and stored at low temperature;

[0050] The composite bacteria are: Bacillus megaterium: Bacillus subtilis: Bacillus fl...

Embodiment 3

[0056] Include the following steps:

[0057] (1) Making steam puffed straw

[0058] Crush the remaining part of the material after harvesting the corn seeds, remove the soil from the material, convey it into the tank with a belt, add steam, pressurize it, and spray it to the puffing bin to obtain steam puffed straw. The puffing process pressure is 2.0Mpa, temperature is 200°C, The time is 5 minutes, and it is sprayed instantly;

[0059] (2) Production of biochemical fulvic acid raw materials

[0060] Steam-expanded straw is added with compound bacteria and mixed evenly, at a temperature of 70-75°C, fermented for 7 days, dried by a low-temperature drying system at a temperature of 75°C, with a moisture content of <10%, stored at room temperature, crushed, and passed through a 100-mesh sieve to obtain Biochemical fulvic acid raw material, sealed and stored at low temperature;

[0061] The composite bacteria are: Bacillus megaterium: Bacillus subtilis: Bacillus flexure=1:1:1; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com