Three-point welding placing support positioning structure

A positioning structure and positioning groove technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of welding slag affecting welding quality, welding slag welding quality, easy running of brackets, etc., to achieve structural Simplification, precise positioning, and accurate corresponding effect of welding points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

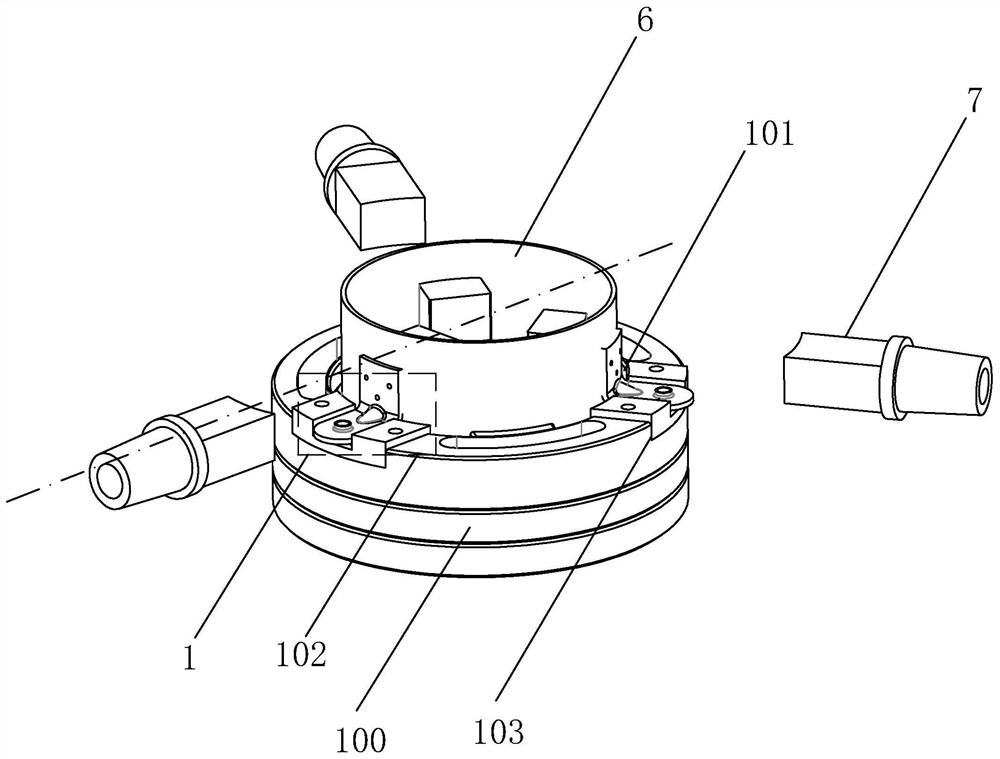

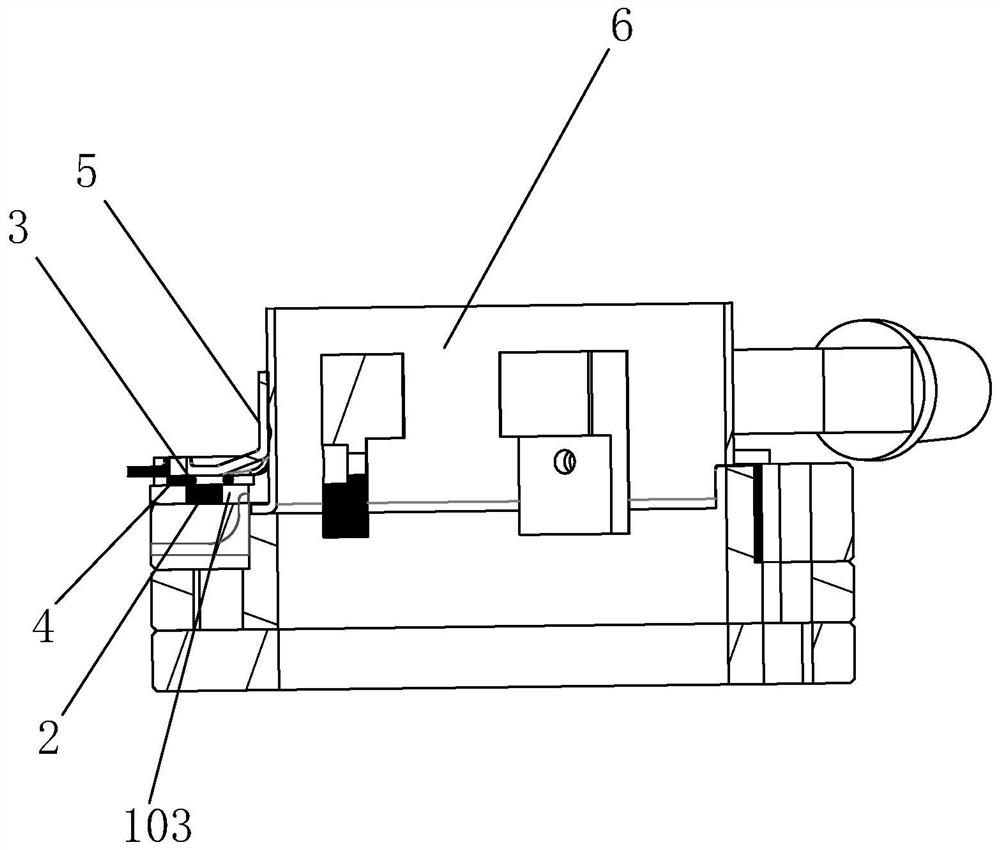

[0021] Such as figure 1 , 2 As shown, a three-point welding placement bracket positioning structure includes a positioning base 100 with a placement groove 101 in the middle, a base 102 is provided on the positioning base 100, and a magnet 2 is arranged in the base 102. The weldment supporting assembly 1 is arranged on the top of the base layer 102 . The magnet 2 can be fixed after the weldment support 5 is placed on the positioning abutment 100, so that no weldment running phenomenon occurs; and the weldment support separates the weldment support 5 from the positioning abutment 100, relying on The gap generated by the separation cooperates with the magnet 2 to absorb and collect the welding slag generated in the welding process of the weldment bracket 5, so as to prevent the welding slag from adhering to the vicinity of the weld bead and affect the welding quality, and effectively improve the welding accuracy and welding quality. The magnet 2 in this embodiment is a permane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com