Preparation method of epoxy coiled material joint mixture

A technology of epoxy coil material and caulking agent, which is applied in the field of caulking agent, can solve the problems of laborious stirring by a stirring device, affecting the synthesis of finished products, and large consistency of caulking agent, and achieves the effect of uniform mixing and uniform mixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of preparation method of epoxy coil joint filler, concrete steps are as follows:

[0034] S1: Ensure that the inside of the main body 1 of the original mixing device is dry, feed the powder into the mixing device through the No. 1 feed port 3 according to the proportion of ingredients, and control the main motor 7 to rotate evenly to obtain a premixed uniform powder;

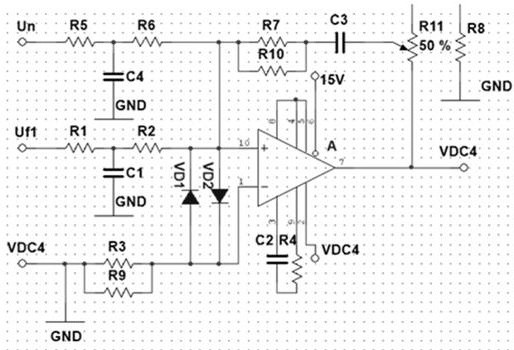

[0035] S2: Weigh a certain amount of liquid material according to the formula and add it to the stirring device. By controlling the ratio of the added powder material to the liquid material, the electric control box 6 is controlled to make the internal raw materials evenly stirred, and the joint filler is obtained;

[0036] The powder material includes quartz sand, shell powder and polysiloxane, and the liquid material includes epoxy resin emulsion, epoxy resin curing agent, resin glue and isopropanol, in parts by weight: 50-100 parts of quartz sand, 100 parts of shell powder -300 parts, polysiloxa...

Embodiment 2

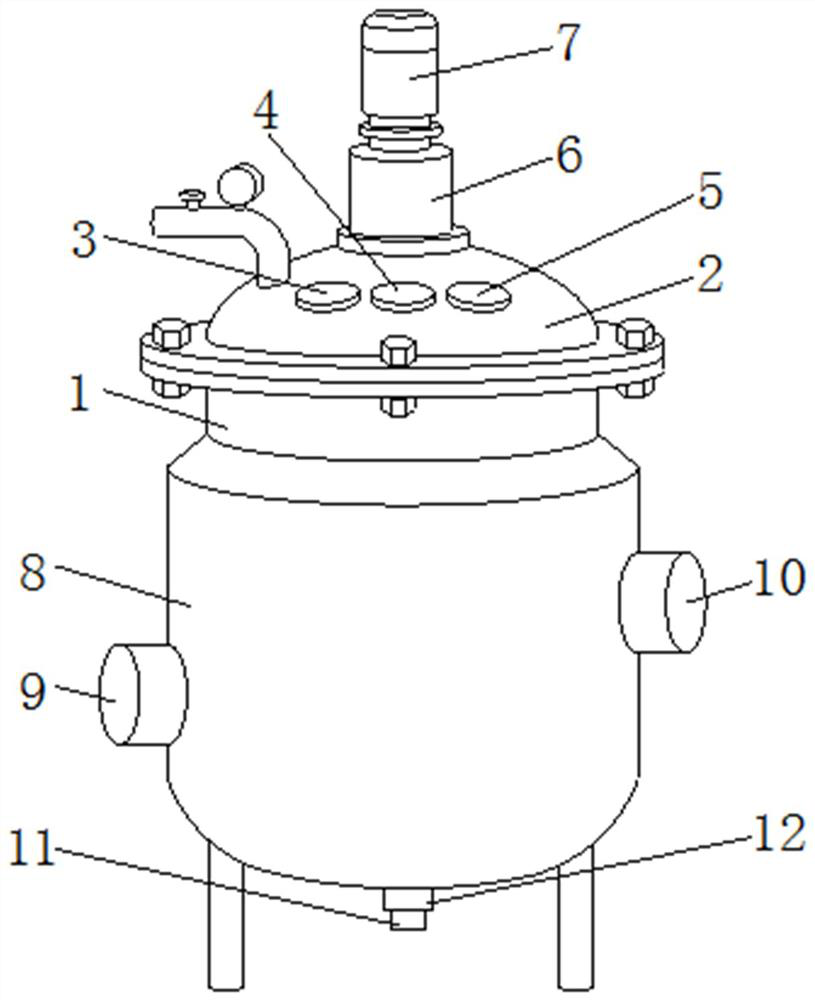

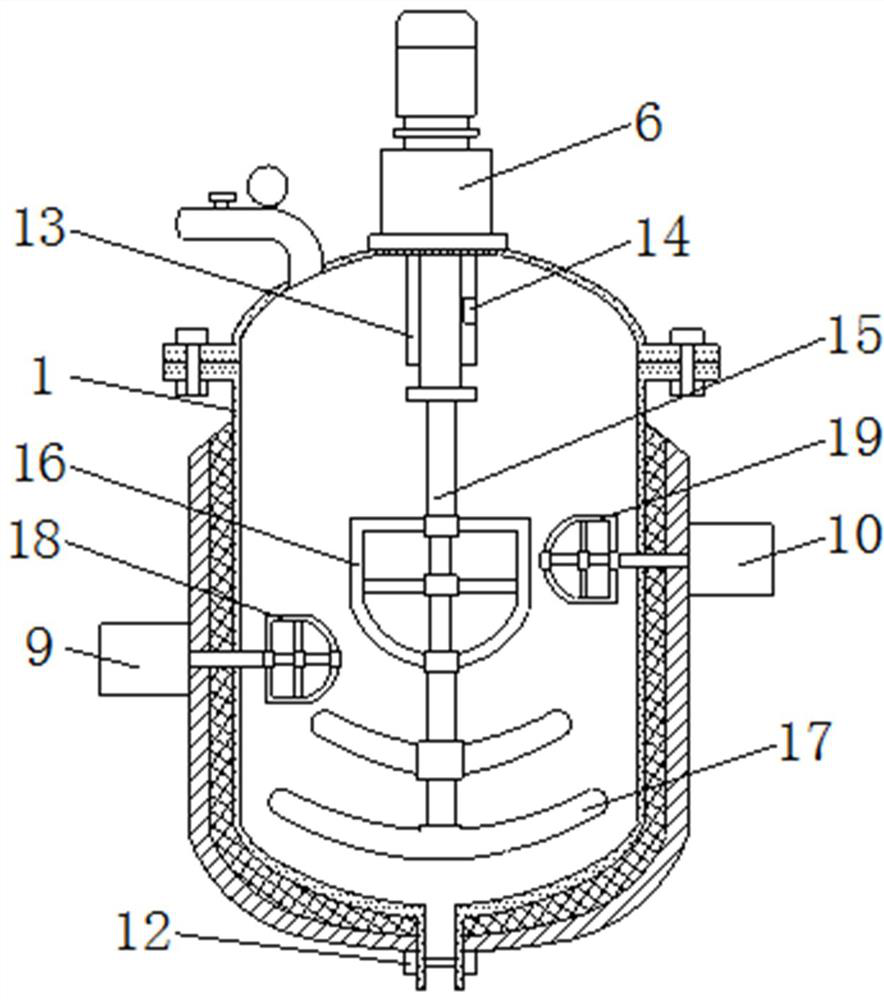

[0039] Such as Figure 1-3 As shown, the present invention also provides a stirring device for acid and alkali resistant epoxy coil sealant, comprising a stirring device main body 1 and an upper cover 2, the upper end of the stirring device main body 1 is fixedly installed with an upper installation Roland, and the lower end of the upper cover 2 The lower installation Roland is fixedly installed, and the upper installation Roland and the lower installation Roland are fixedly connected by bolts. It is characterized in that an electric control box 6 is fixedly installed on the upper end of the upper cover 2, and a control panel is fixedly installed on the outer surface of the front end of the electric control box 6. , the upper end of the upper cover 2 is also provided with No. 1 feed port 3, No. 2 feed port 4 and No. 3 feed port 5, and No. 1 feed port 3, No. 2 feed port 4 and No. 3 feed port 5 They are all located at the front end of the electric control box 6, and the outer su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com