Dough kneading machine system

A technology of dough mixer and hardware system, applied in the field of dough mixer system, can solve the problems of low degree of automation of dough mixer, inability to be processed in time, low per capita production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention and its beneficial technical effects will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments. The A, B, C, and D suffixes of the integrated circuit numbers appearing in the accompanying drawings indicate the functional unit circuits of the integrated circuits. For the convenience of expression, some parts of the circuit diagrams in the attached drawings use network symbols instead of electrical connecting lines. The dough mixer structure of the electromechanical device of the hardware system is an existing technology, and the applicant can refer to the patent application number "CN201820532126.7" and the utility model patent named "Dough Mixer".

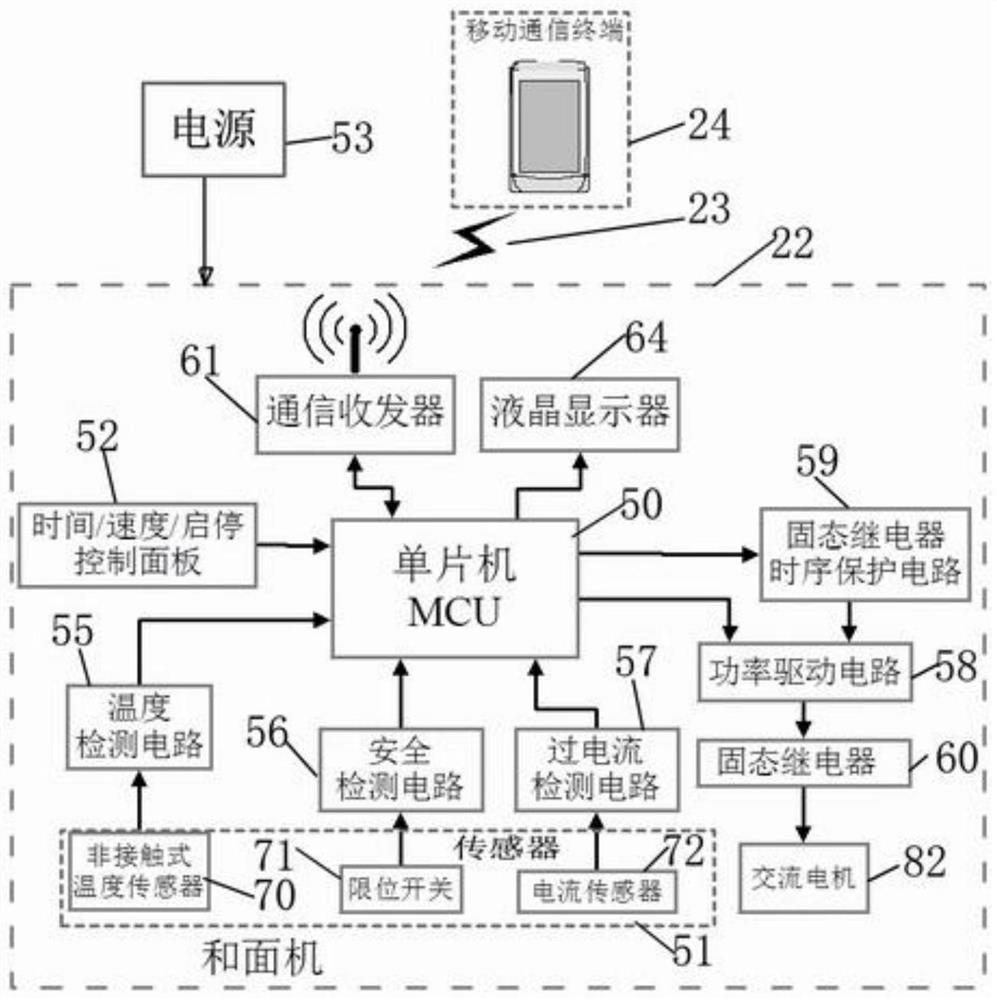

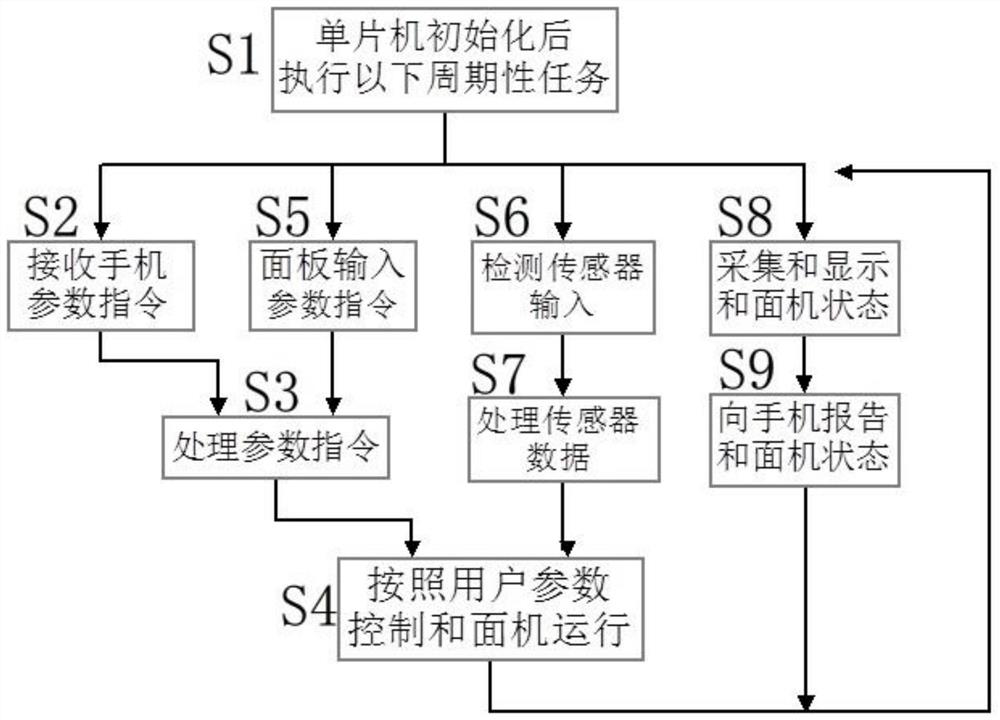

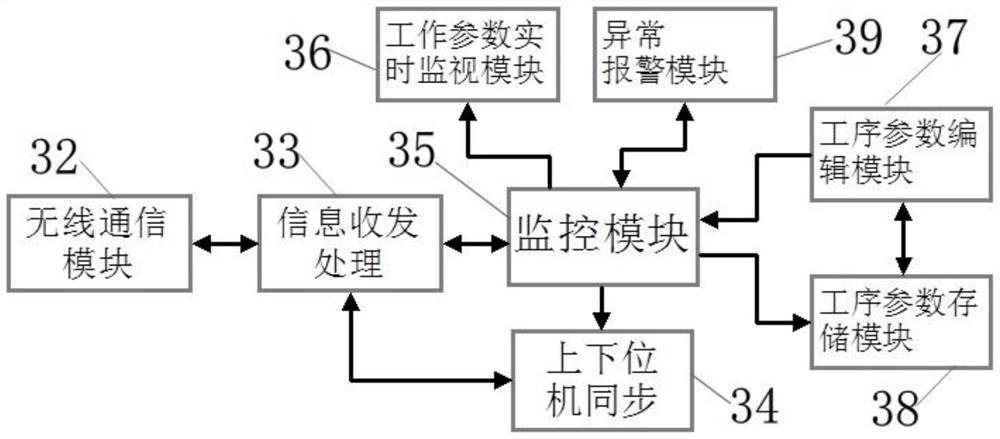

[0061] see figure 1 , a dough mixing machine system, comprising a dough mixing machine hardware system 22, a wireless network system 23, and a control system; The communication terminal 24, the mobile communication terminal 24 and the controller a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com