Bearing axial play detection mechanism

A technology of axial clearance and detection mechanism, which is applied in the direction of mechanical clearance measurement, measuring devices, and mechanical devices, etc., can solve the problems of reduced work efficiency, damage, and no fixed bearing, etc., and achieves the advantages of easy fixed placement and prevention of dumping damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

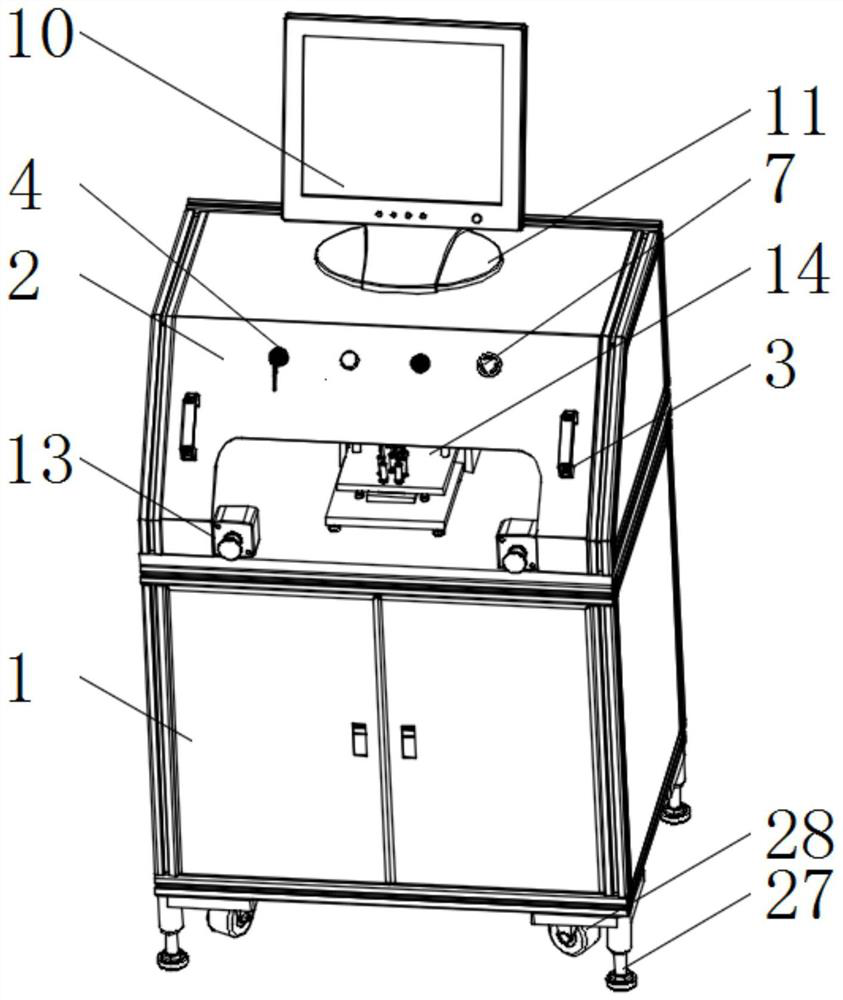

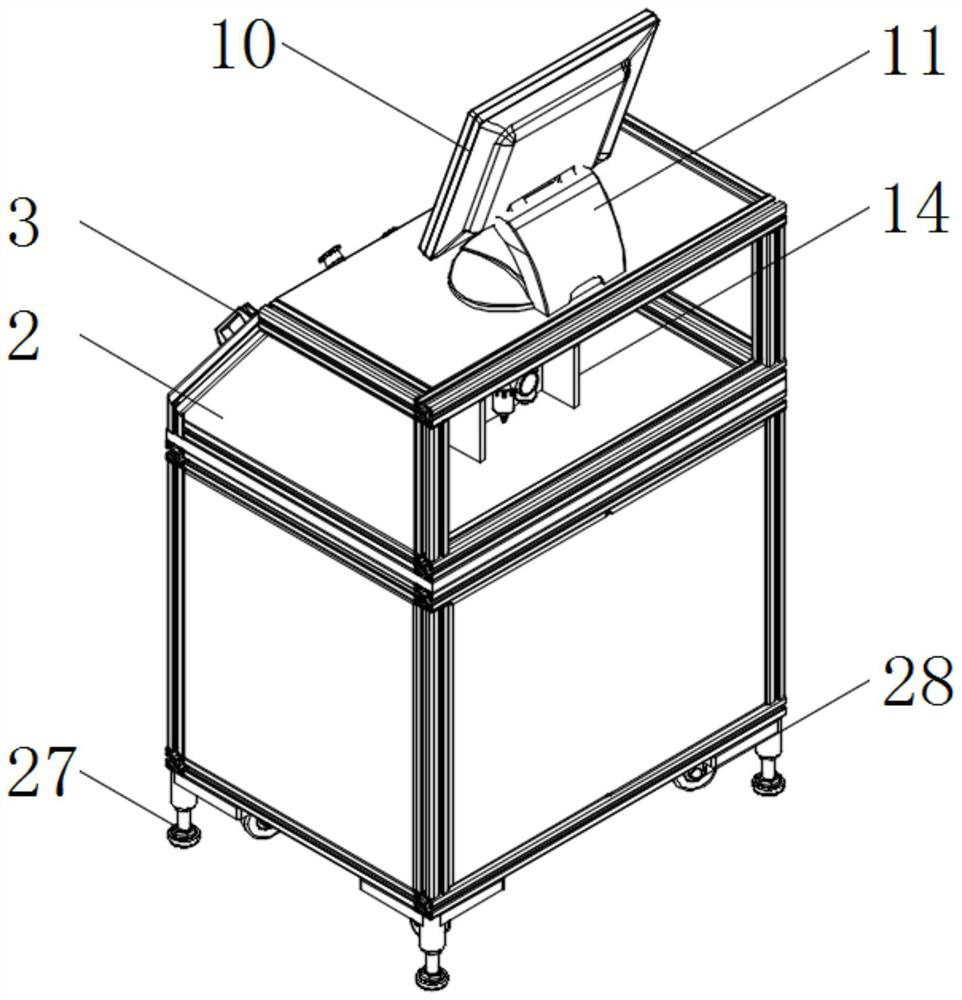

[0029] Such as figure 1 , 3 As shown, a bearing axial clearance detection mechanism includes a mechanism main body 1, a protective cover 2 is provided on the outer surface of the upper end of the main body 1, a connecting groove 8 is provided on the outer surface of the upper end of the protective cover 2, and the inside and outside of the connecting groove 8 are The surface is provided with a mounting groove 9, the upper side of the protective cover 2 is provided with a display screen 10, the outer surface of the lower end of the display screen 10 is provided with a support frame 11, the outer surface of the lower end of the support frame 11 is provided with a mounting column 12, and the upper end of the mechanism body 1 A detection device 14 is arranged near the lower end of the protective cover 2, a support platform 15 is provided on the outer surface of the upper end of the detection device 14, an auxiliary sleeve 16 is provided on the outer surface of the support platform...

Embodiment 2

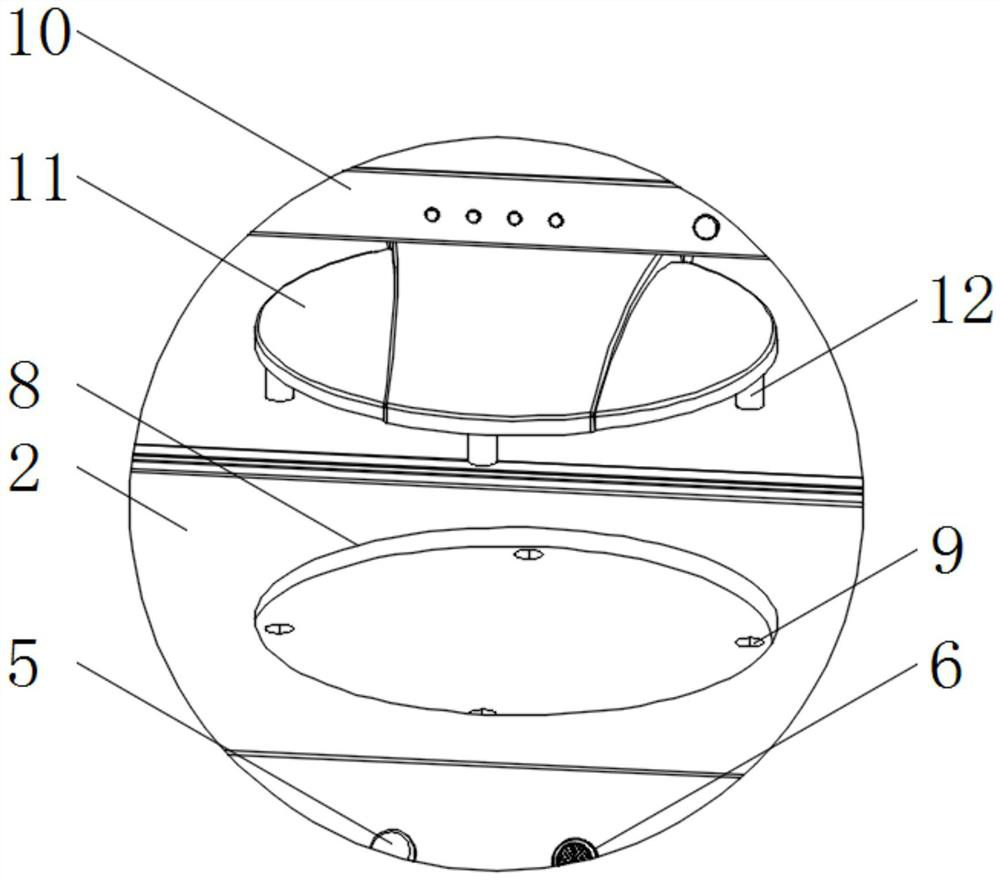

[0032]On the basis of Example 1, as figure 2 As shown, the main body of the mechanism 1 and the protective cover 2 are fixedly connected, and the protective cover 2 is made of non-metallic material. There is an indicator light 5, and a buzzer 6 is provided on the outer surface of the front end of the protective cover 2 close to the indicator light 5, and the buzzer 6 is electrically connected to the main body 1 of the mechanism, and the outer surface of the front end of the protective cover 2 is close to the buzzer. One side of the buzzer 6 is provided with an emergency stop button 7, and the emergency stop button 7 has a cylinder rotation pressing structure, which is beneficial to the use of the buzzer 6 and the emergency stop button 7 during the use of the mechanism main body 1.

[0033] There is a fixed connection between the protective cover 2 and the display screen 10, and a conductive connection between the display screen 10 and the mechanism main body 1, and a fixed co...

Embodiment 3

[0035] On the basis of embodiment one and embodiment two, such as Figure 4 , 5 , 6, the mechanism main body 1 and the detection device 14 are flexibly connected, and the detection device 14 is made of metal material, and the detection device 14 and the support platform 15 are fixedly connected, and the width of the support platform 15 is the same as that of the detection device. 14 have the same width, the outer surface of the supporting platform 15 is provided with auxiliary sleeves 16, and the number of auxiliary sleeves 16 is arranged in two groups, and the inner side of the auxiliary sleeves 16 is movably connected with auxiliary rods 17, and the auxiliary rods 17 are The cylindrical structure is convenient for moving and using the detection fixed plate 18, and the number of auxiliary rods 17 is arranged in two groups symmetrically, which is beneficial to the placement and use of the detection device 14.

[0036] The auxiliary rod 17 is fixedly connected with the detecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com