A miniature two-stage vortex pump hydraulic thruster

A flow propeller, hydraulic technology, applied in the direction of pumps, axial flow pumps, pump components, etc., can solve the problems of short service life, high operating cost, high maintenance cost, weak anti-corrosion performance of electric flow propeller, etc., and achieves easy on-site installation. , to meet anti-corrosion requirements, to meet the effect of explosion-proof requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0116] The present invention will be described in more detail below with reference to schematic diagrams, wherein preferred embodiments of the present invention are shown, and it should be understood that those skilled in the art can modify the present invention described herein while still achieving the advantageous effects of the present invention. Therefore, the following description should be understood as the broad knowledge of those skilled in the art, but not as a limitation of the present invention.

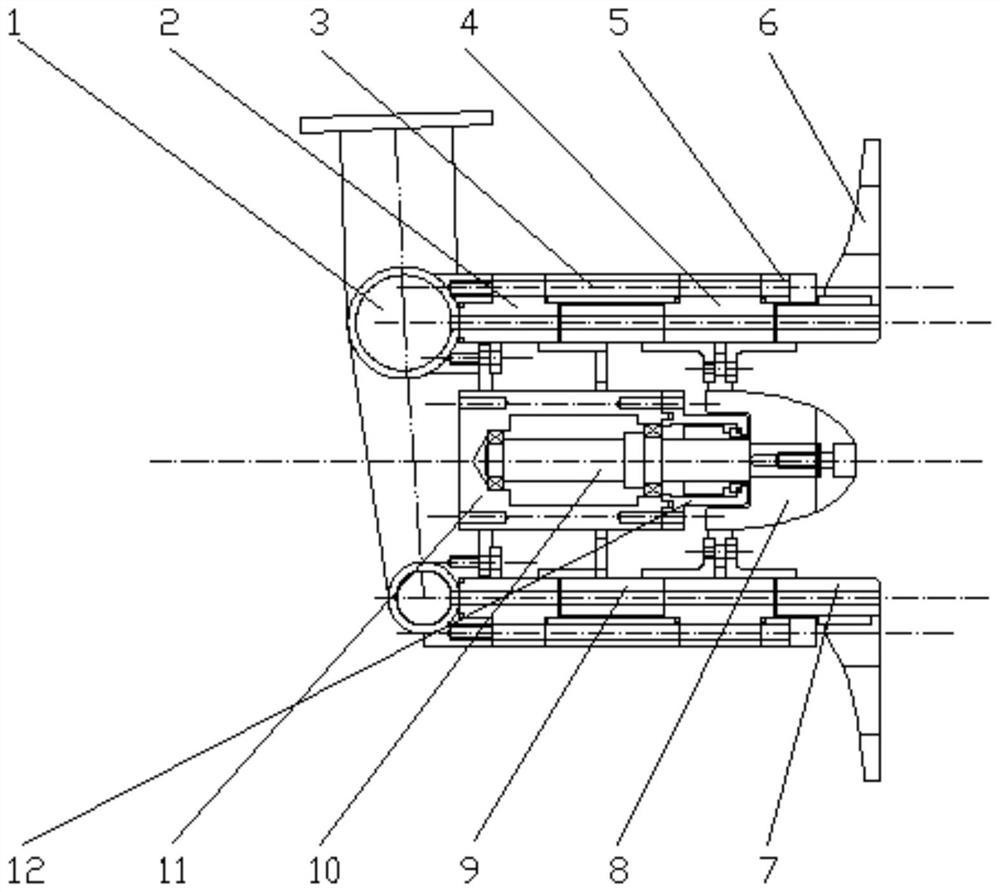

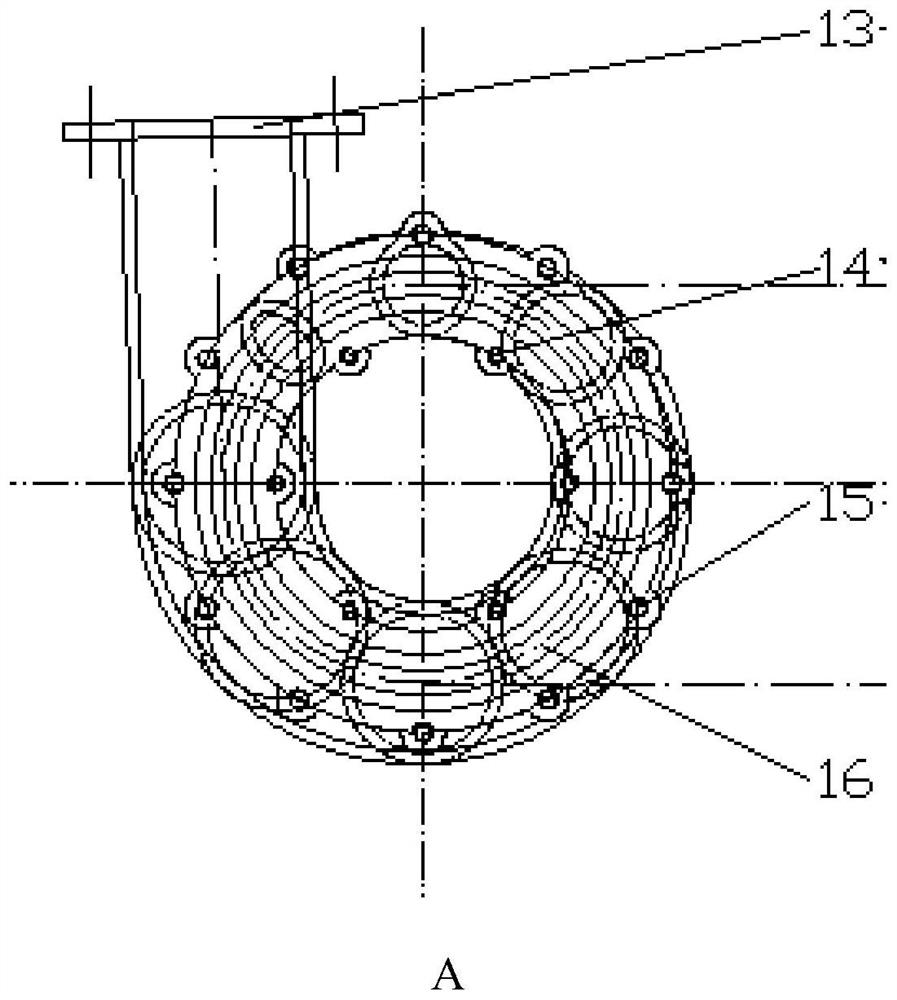

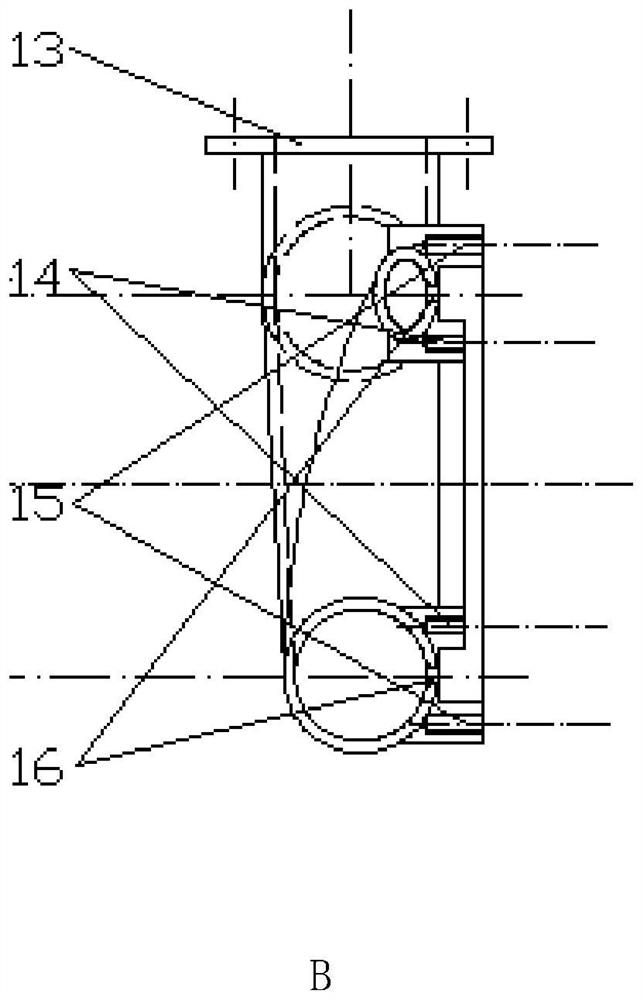

[0117]A miniature two-stage vortex pump hydraulic thruster developed for a sewage treatment plant that requires the input shaft power of the thruster to be 2.5 kilowatts, with a speed of 680 rpm and a cascade of two-stage turbines. The flow rate is 54.41 cubic meters per hour. In order to reduce the flow rate as much as possible, the miniature two-stage vortex pump hydraulic thruster turbine invented by cascading two-stage turbines is adopted. The unit specific speed is 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com