Nano rhenium molybdenum alloy-graphene composite lubricating oil additive

A lubricating oil additive and graphene composite technology, applied in the direction of additives, petroleum industry, lubricating composition, etc., can solve the problem of easy aging or damage of lubricating film, and achieve the protection of metal surface, good lubricity and wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

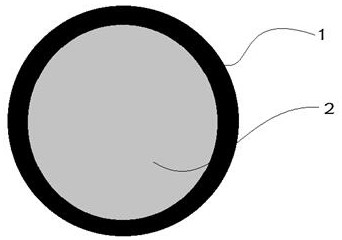

Image

Examples

Embodiment 1

[0037] (1) Add graphene oxide into ethanol, and disperse evenly to obtain an ethanol dispersion of graphene oxide with a concentration of 10%;

[0038] (2) Spray a hydrogen peroxide solution with a mass concentration of 35% on the surface of the nano-rhenium-molybdenum alloy powder. The amount of hydrogen peroxide solution is 1.5% of the mass of the nano-rhenium-molybdenum alloy powder to make the nano-rhenium-molybdenum alloy powder slightly wet, and then Static treatment for 2.5h, so that defects appear on the surface of the nano-rhenium-molybdenum alloy powder, and obtain nano-rhenium-molybdenum alloy powder with surface defects;

[0039] (3) Add 32.5 kg of surface-defect nano-rhenium-molybdenum alloy powder into 100 kg of graphene oxide ethanol dispersion, then add 2 kg of sodium dodecylbenzene sulfonate, and disperse ultrasonically for 25 min with a power of 800 W and a frequency of 25 kHz, so that Graphene oxide is dispersed on the surface of nano-rhenium-molybdenum allo...

Embodiment 2

[0043] (1) Add graphene oxide into ethanol and disperse evenly to obtain an ethanol dispersion of graphene oxide with a concentration of 8%;

[0044] (2) Spray a hydrogen peroxide solution with a mass concentration of 32% on the surface of the nano-rhenium-molybdenum alloy powder. The amount of hydrogen peroxide solution is 1.2% of the mass of the nano-rhenium-molybdenum alloy powder to make the nano-rhenium-molybdenum alloy powder slightly wet, and then Static treatment for 2 hours, so that defects appear on the surface of the nano-rhenium-molybdenum alloy powder, and obtain nano-rhenium-molybdenum alloy powder with surface defects;

[0045] (3) Add 31kg of nano-rhenium-molybdenum alloy powder with surface defects into 100kg of graphene oxide ethanol dispersion, then add 1.5kg of sodium dodecylbenzenesulfonate, and disperse ultrasonically for 28min with a power of 760W and a frequency of 22kHz, so that Graphene oxide is dispersed on the surface of nano-rhenium-molybdenum allo...

Embodiment 3

[0049] (1) Add graphene oxide into ethanol, and disperse evenly to obtain an ethanol dispersion of graphene oxide with a concentration of 12%;

[0050] (2) Spray a hydrogen peroxide solution with a mass concentration of 38% on the surface of the nano-rhenium-molybdenum alloy powder. The amount of hydrogen peroxide solution is 1.8% of the mass of the nano-rhenium-molybdenum alloy powder to make the nano-rhenium-molybdenum alloy powder slightly wet, and then Static treatment for 3 hours, so that defects appear on the surface of the nano-rhenium-molybdenum alloy powder, and obtain nano-rhenium-molybdenum alloy powder with surface defects;

[0051] (3) Add 34kg of nano-rhenium-molybdenum alloy powder with surface defects into 100kg of graphene oxide ethanol dispersion, then add 2.5kg of sodium dodecylbenzenesulfonate, and ultrasonically disperse for 22min with a power of 840W and a frequency of 28kHz, so that Graphene oxide is dispersed on the surface of nano-rhenium-molybdenum al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com