Electrochemical water removal method and system for stripping liquid waste liquid

A stripping solution and electrochemical technology, applied in chemical instruments and methods, separation methods, water/sewage treatment, etc., can solve the problem of high energy consumption, and achieve the effect of realizing waste liquid recovery, zero energy consumption, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

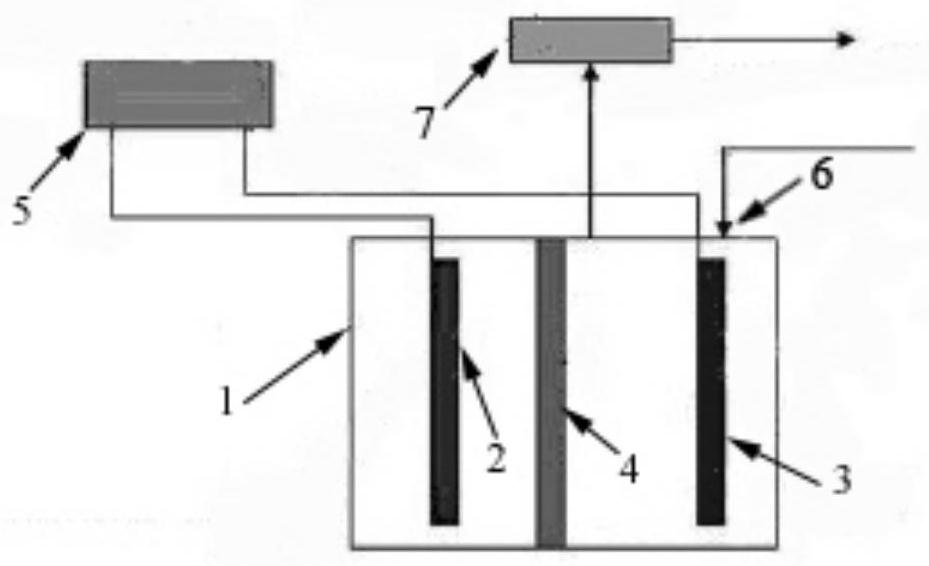

[0028] An electrochemical water removal system for stripping liquid waste liquid, the structure is as follows figure 1 shown. Depend on figure 1 It can be seen that the system includes an external power supply, a battery assembly, a waste liquid storage tank and a finished product storage tank; the battery assembly includes an electrochemical reaction cell casing 1, an air cathode 2, a metal anode 3 and an insulating diaphragm 4; the connection between the metal anode 3 and the air cathode 2 There is an insulating diaphragm 4 between them, the insulating diaphragm is a selectively permeable film, the material of the insulating diaphragm is thermosetting epoxy resin, and the insulating diaphragm is chemically compatible with the stripping liquid waste liquid.

[0029] Electrochemical reaction tank shell 1 is filled with electrolyte, which is the waste liquid of the stripper to be treated; metal anode 3 and air cathode 2 are connected to external power supply 5; electrochemical...

Embodiment 2

[0035] The electrochemical dewatering system in Example 1 is used to dewater the stripping liquid waste liquid. The stripping liquid waste liquid enters the inside of the electrochemical dewatering system through the liquid inlet and then flows through the metal anode, air cathode and insulating diaphragm. Consumed in the reaction process The anode metal and the water in the stripper waste liquid simultaneously form reactants in a precipitated state, achieving the purpose of material separation and water removal at the same time. Specifically include the following steps:

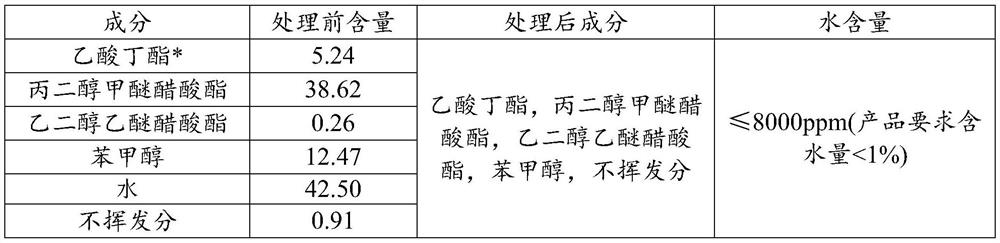

[0036] (1) The metal anode and the air cathode are connected to the external power supply respectively, and the water-containing stripping solution waste liquid (the composition of the Thinner100% dilution liquid waste liquid is shown in Table 1) enters the electrochemical water removal system through the liquid inlet of the shell, and simultaneously with The metal anode, the air cathode and the gas passing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com